[0002] In the

civil engineering, thermal insulation, and

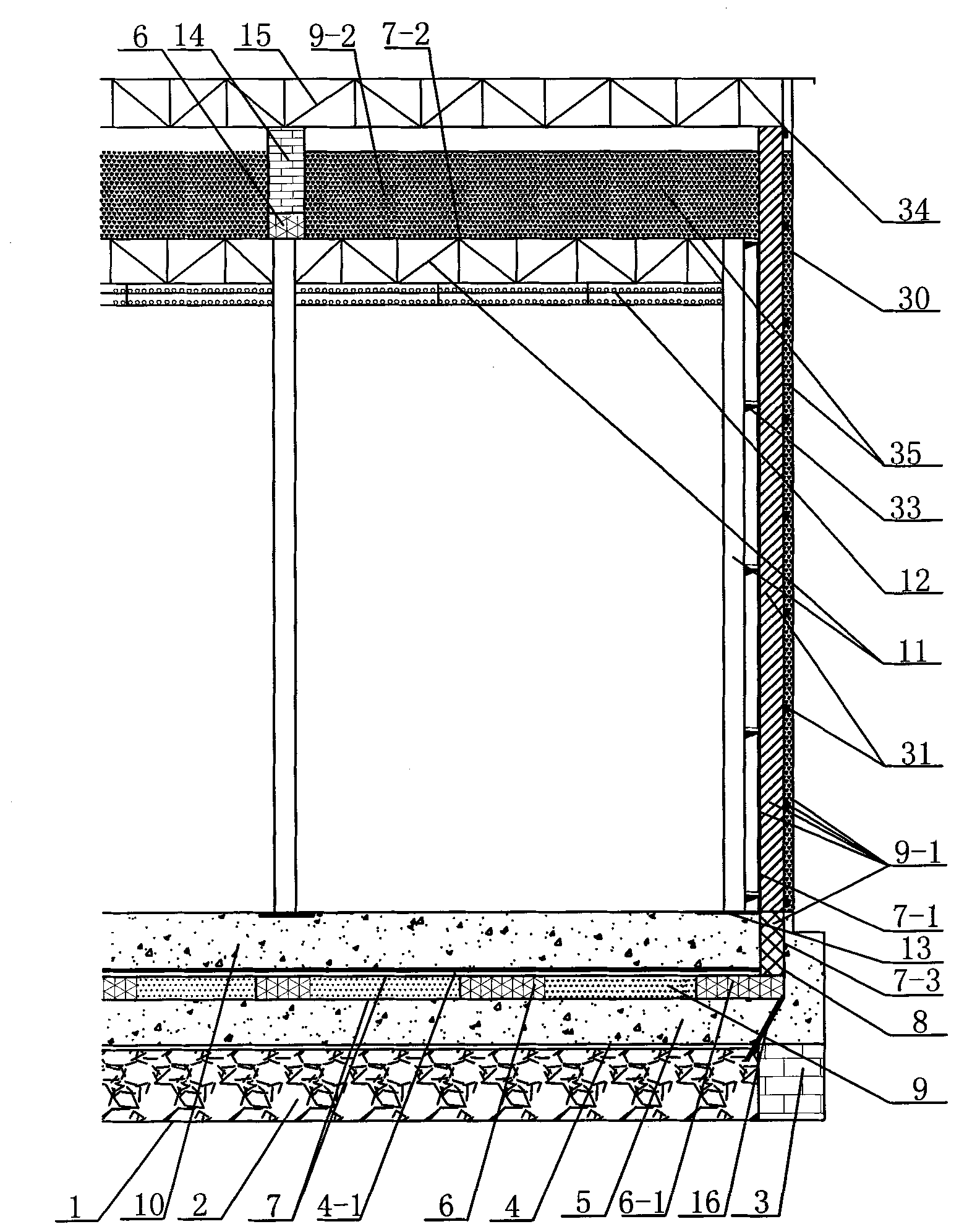

refrigeration systems of the existing civil steel structure slab thermal insulation cold storage, due to the lack of a fully enclosed waterproof and

moisture barrier system for protecting the thermal insulation layer, or only fragmentary waterproof and

moisture barrier layers, the existing civil steel structure Since the day when the plate-type thermal insulation cold storage was established, its insulation layer material has been soaked by the moisture inside and outside the cold storage to the insulation layer material, so that the insulation function of the insulation material has been continuously reduced; the insulation layer material in the ground is fully enclosed waterproof and moisture-proof , the top and bottom of the insulation layer are soaked by water inside and outside the cold storage; the connection between the insulation layer material in the ground and the wall insulation board forms a gap, the connection gap between the wall and roof insulation board and the fixed insulation board. , easy to soak and conduct cold; the wall and roof insulation boards are internally and externally pressed color

steel plates, and internally bonded with thermal insulation materials. The connection between the boards is a hook connection, and the boards are fixed on the steel structure with nylon or plastic bolts , which itself has insurmountable defects. One of the protruding parts of the inner color steel plate is protruding from the insulation layer, which reduces the thickness of the insulation layer; the connection between the second board and the board is a hook connection. It is impossible to fill in the insulation material again, there are no gaps and the size of the gaps cannot be known, forming a natural cooling gap; the maximum width of the three boards is about 1 meter, and after the completion of the warehouse, multiple connection gaps are formed, which are easy to conduct cold; the four nylon or plastic The bolts pass through the insulation board and are fixed on the steel structure, and the gap formed by the passage is easy to soak in moisture and conduct cold; the pressure-shaped color steel inside and outside the five-wall and roof insulation board is directly bonded to the insulation material, which is a material that is easy to conduct cold. That is, the cold inside the warehouse is easily conducted to the pressure-shaped color steel plate inside the warehouse, and the heat outside the warehouse is easily transmitted to the pressure-shaped color steel plate outside the warehouse.

And because there is no Rubik's Cube support in the ground insulation layer of the existing civil steel structure slab cold storage, the material of the insulation layer is insufficient for the

reinforced concrete on the load-bearing ground and the goods carried. Cracks are formed, which are easy to soak and conduct cold; the Rubik's Cube is a

solid cube composed of non-easy cold conduction materials, which also has the functions of heat preservation and support. In the layer, there is an independent fully enclosed waterproof and moisture-proof layer system for thermal insulation and load-bearing objects; the steel structure of the existing civil steel structure slab thermal insulation cold storage is mainly to support the storage plate, and the distance between the roofs is mostly about 4 meters. This structure cannot The pipes of the cold storage are hoisted, so the cooling part is mostly air-cooled by the

evaporator. The inherent defects of the air-cooled

evaporator are: the

evaporation area is small, the

frost must be continuously heated, the

power consumption and the storage temperature are continuously increased, and the storage temperature is unstable. The cold wind is easy to dry the stored goods, and form wind and

dust pollution, and the quality of

refrigeration is poor; the roof waterproof of the existing civil steel structure plate cold storage is to build a layer of steel structure color steel plate waterproof on the roof insulation board, and the roof waterproof steel structure is fixed in the warehouse On the steel structure, the load-bearing part is the roof color steel insulation board, the roof color steel insulation board is not waterproof, the roof steel structure color steel plate is waterproof, after installation, it will deform and become thinner, and the fixed roof color steel structure is formed through the roof color steel insulation board The gaps are easy to get wet and lead to cold; the existing civil

engineering steel structure slab thermal insulation cold storage has formed a congenital lack of a fully enclosed waterproof and

moisture barrier system that must be included in the thermal insulation layer since the day it was established, and the cold storage system is incomplete; resulting in freezing, The quality of cold storage keeps declining, the daily

temperature difference is large, the

economic benefits are gradually reduced, the cold storage consumes a lot of

electricity, the cold energy is lost quickly, the production cost is high, and the construction cost is high

Login to View More

Login to View More  Login to View More

Login to View More