Gear pump

一种齿轮泵、齿轮花的技术,应用在泵、皮带/链条/齿轮、活塞泵等方向,能够解决部件数量增加、大型化、齿轮泵周边构造复杂化等问题,达到抑制部件数量、抑制增加的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

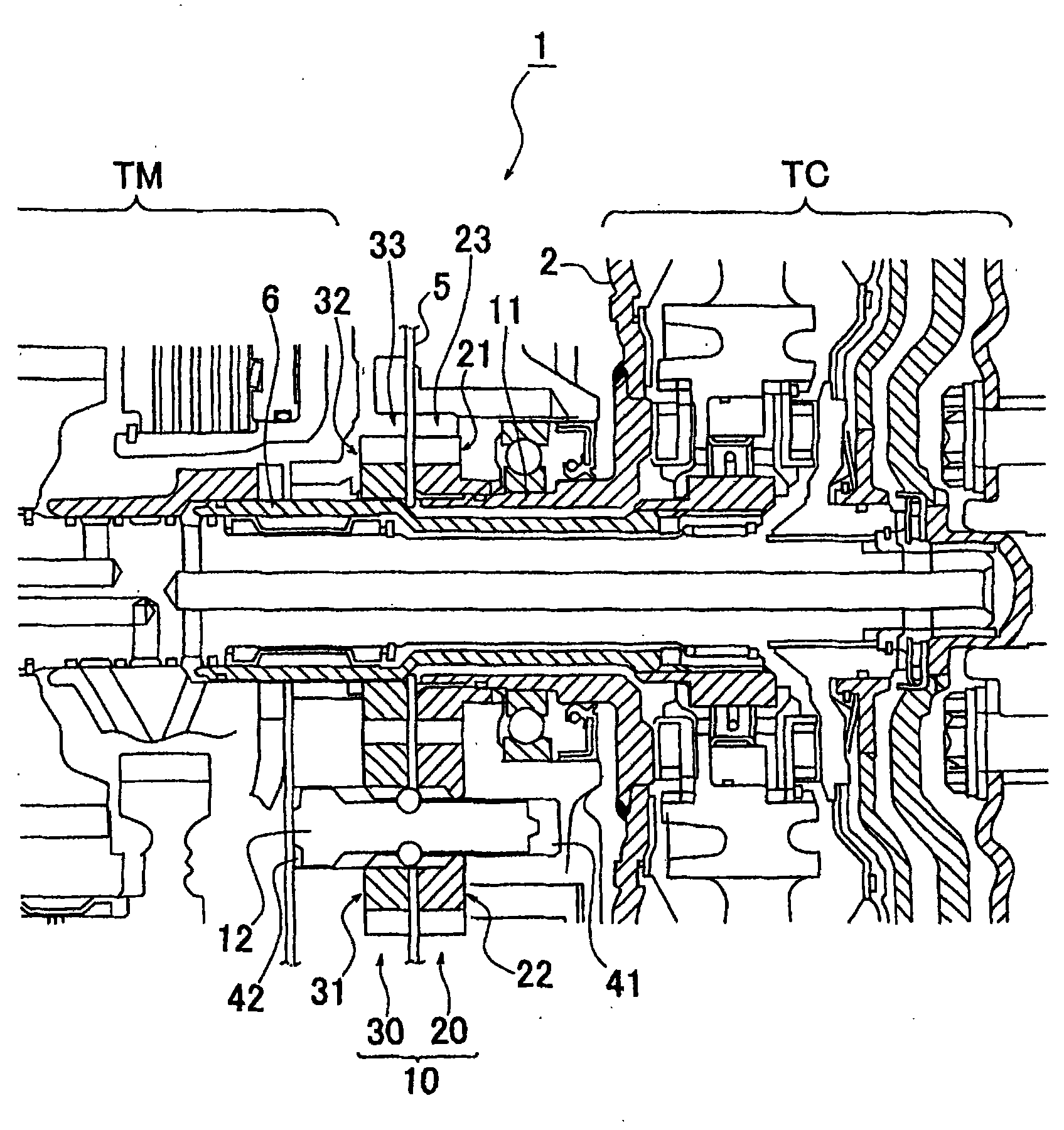

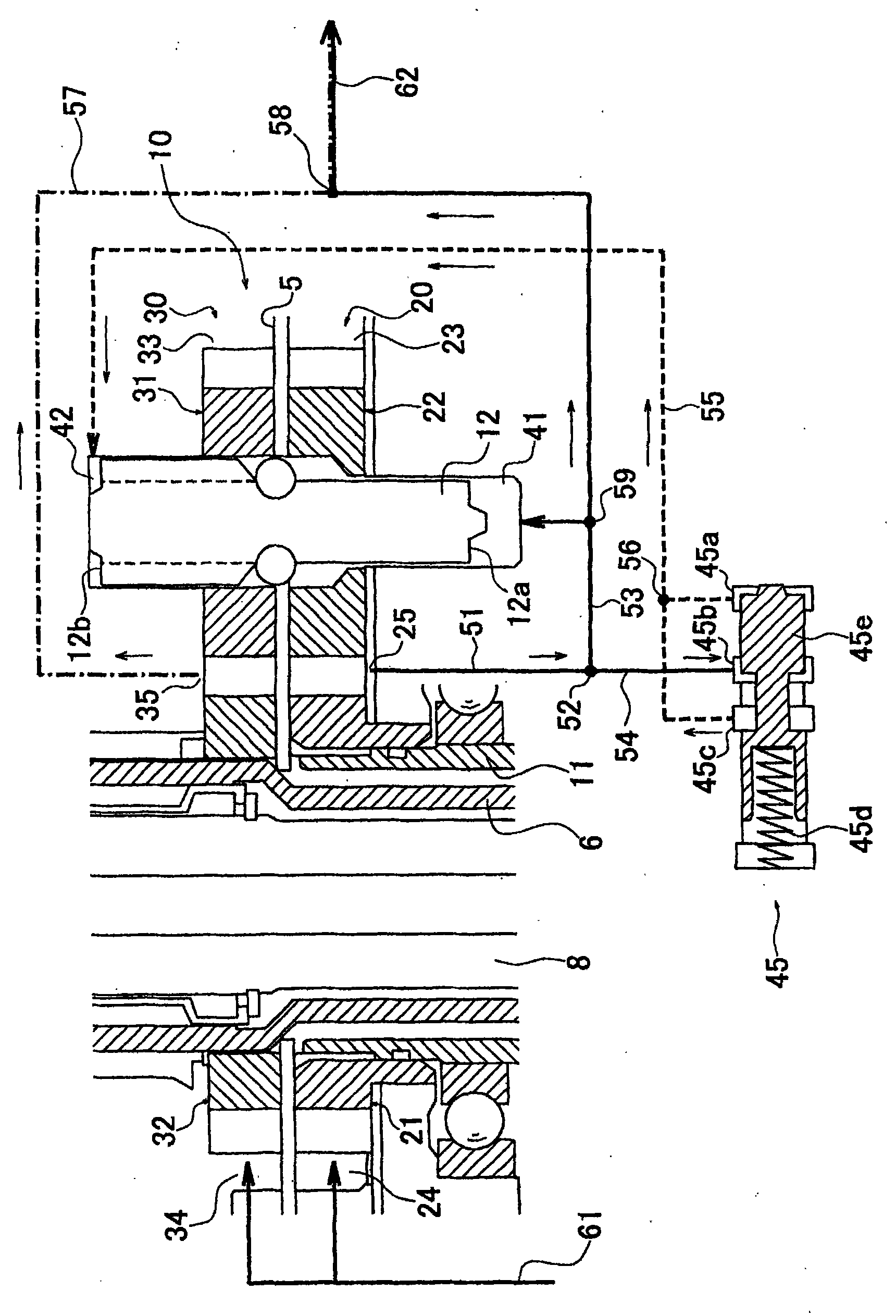

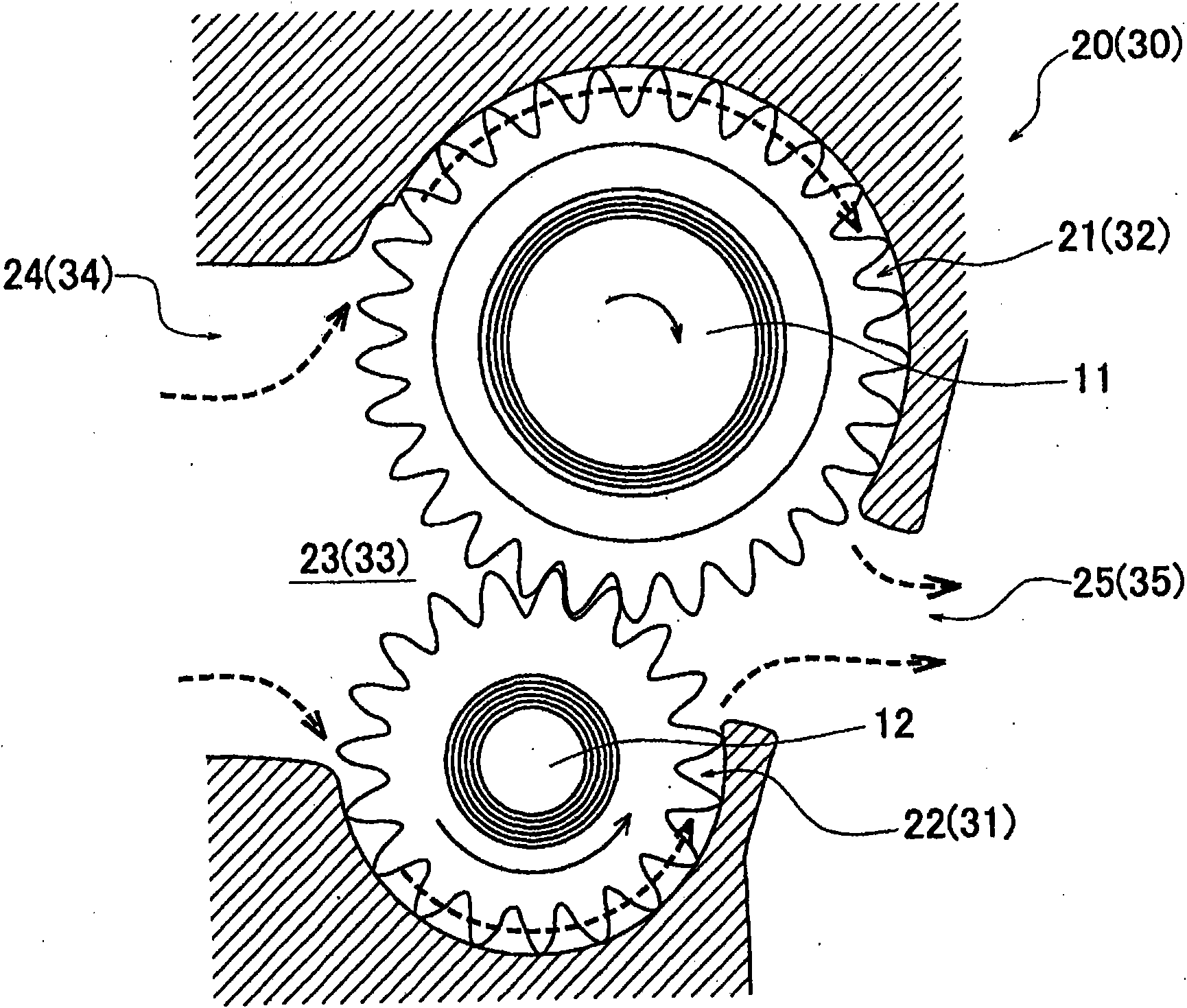

[0026] figure 1 It is a partial side cross-sectional view of an automatic transmission including an oil pump (gear pump) 10 according to the first embodiment of the present invention. and, figure 2 is a side sectional view for explaining the detailed structure of the oil pump 10, image 3 It is a schematic side view of the oil pump 10 viewed from the axial direction of the drive shaft 11 and the rotation shaft 12 described later. figure 1 The illustrated automatic transmission 1 includes a torque converter TC for amplifying and outputting torque input from an engine (not shown), a transmission mechanism TM for realizing predetermined shift speeds, and further includes a torque converter TC for amplifying and outputting torque input to each of the automatic transmission 1 . An oil pump 10 that partially supplies working oil and lubricating oil (hereinafter both are referred to as "working oil").

[0027] Oil pump 10 is provided between torque converter TC and transmission m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com