Thermal transfer apparatus, system and method

A heat transfer system and heat source technology, applied in the field of heat transfer systems, can solve problems such as system hazards and affecting the performance of cooling system heat transfer systems, and achieve low manufacturing and assembly time and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

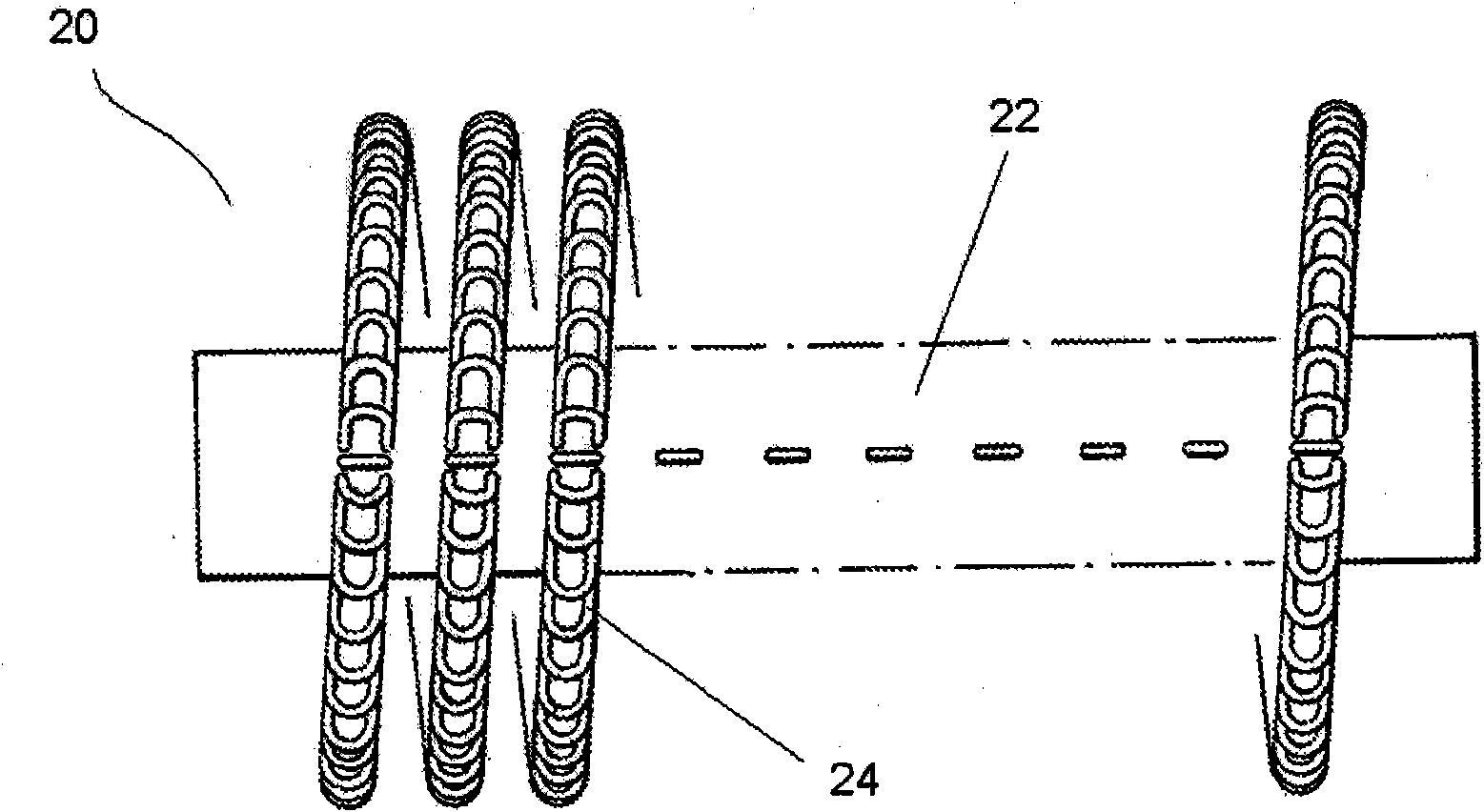

[0080] refer to image 3 , the overall cooling circuit (40, 41, 42) includes fluidly in series: a fluid supply conduit portion (41) having a fluid inlet (54) for connecting to a fluid outlet of a heat source (14); a heat exchange portion ( 40), comprising a heat exchange tube having at least one heat exchange element disposed thereon; and a fluid transfer pipe portion (42), having a fluid outlet (52) for connecting to an inlet of a storage tank (12) to transfer fluid Return to heat source (14). Accordingly, the fluid supply conduit section (41), heat exchange tube and fluid transfer tube section (42) are integrally formed to form a common tube structure (40, 41, 42) manufactured from a single material, eg as a single extrusion.

[0081] An integral cooling circuit (40, 41, 42) may be connected between the heat source (14) and a separate storage tank (12), wherein the fluid inlet (54) of the integral cooling circuit (40, 41 , 42) is connected to the heat source ( 14), and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com