Precipitation method of horizontal flow tank

A technology of advection tanks and retaining walls, applied in separation methods, chemical instruments and methods, settling tanks, etc., can solve problems such as poor sedimentation effect and poor sedimentation effect of advection tanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

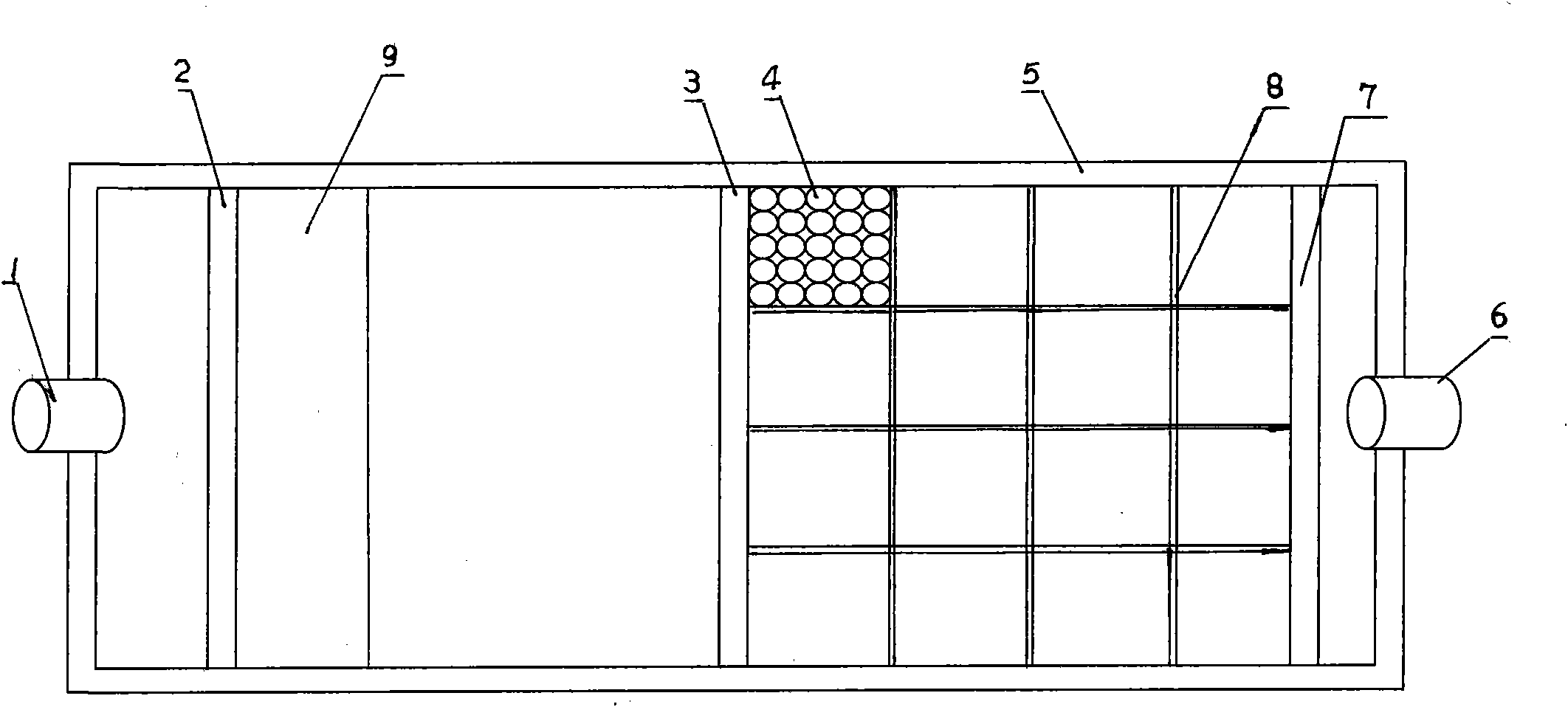

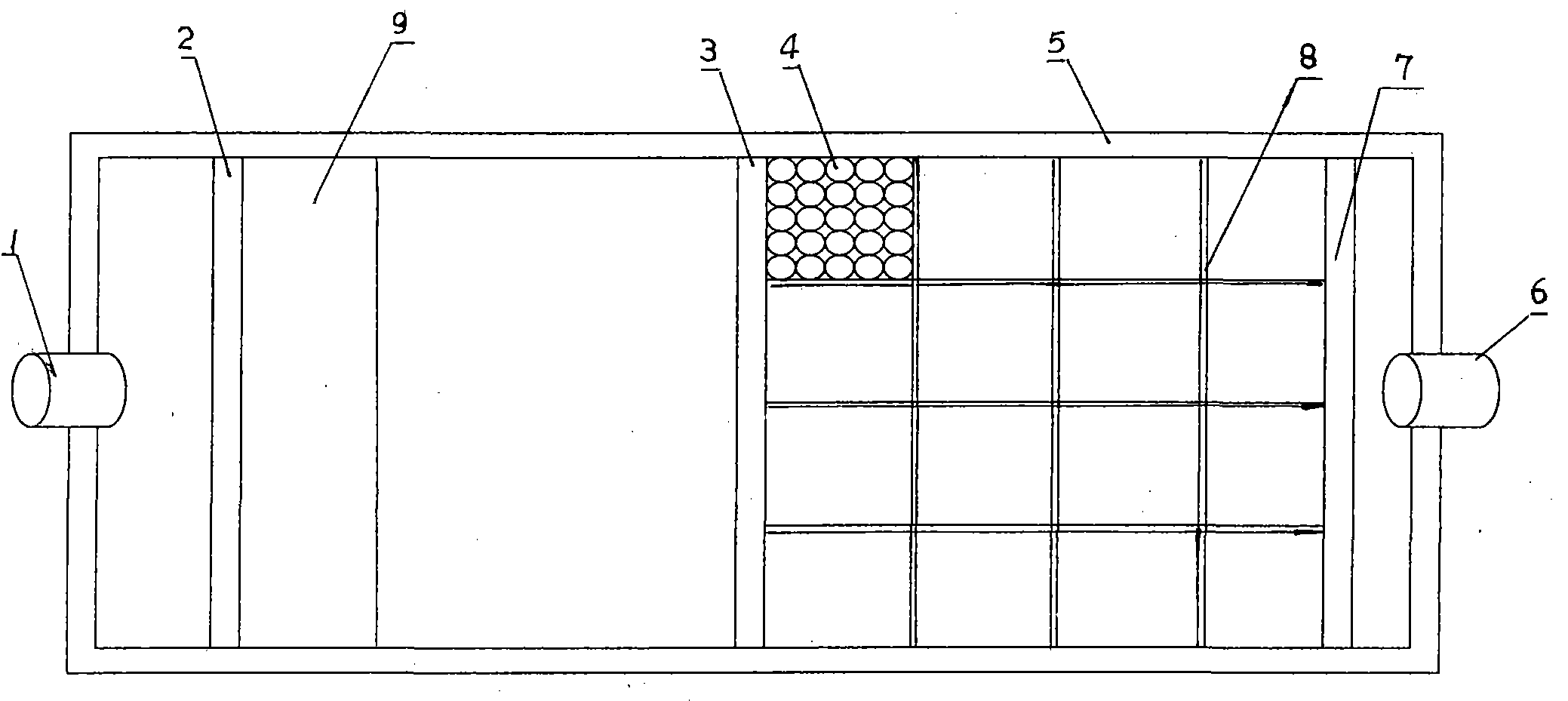

[0011] The present invention is put on trial in the turbid ring advection pool of the mixed line pumping station of Taiyuan Iron and Steel Energy Power Plant, and the designed water treatment capacity of the advection pool is 300-350m 3 / h, upstream water SS≤100mg / l, due to production speed up, water consumption increased to 350--425m 3 / h, and due to changes in the rolling plate, the upstream water SS increases, reaching a maximum of 210mg / l. As a result, the water treatment capacity of the system is insufficient, and the SS of the effluent seriously exceeds the standard. In order to ensure the quality of the effluent, a 175m3 / h filter was added, and the quality of the effluent was improved, but still exceeded the standard. The main reason is that the water flow in the advection pool is too fast and the sedimentation effect is poor, but the advection pool cannot be expanded due to geographical limitations.

[0012] The advection pool is 10 meters long, oriented north-south,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com