Oil pump device of pipe cutter

A pipe cutting machine and oil pump technology, which is applied in the field of oil pumps, can solve the problems that the jack cannot achieve fast feed, the machine cannot work normally, and the pressure cannot be adjusted, so as to achieve the effects of compact structure, improved life, and preventing oil from entering the oil cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, patent of the present invention is described further.

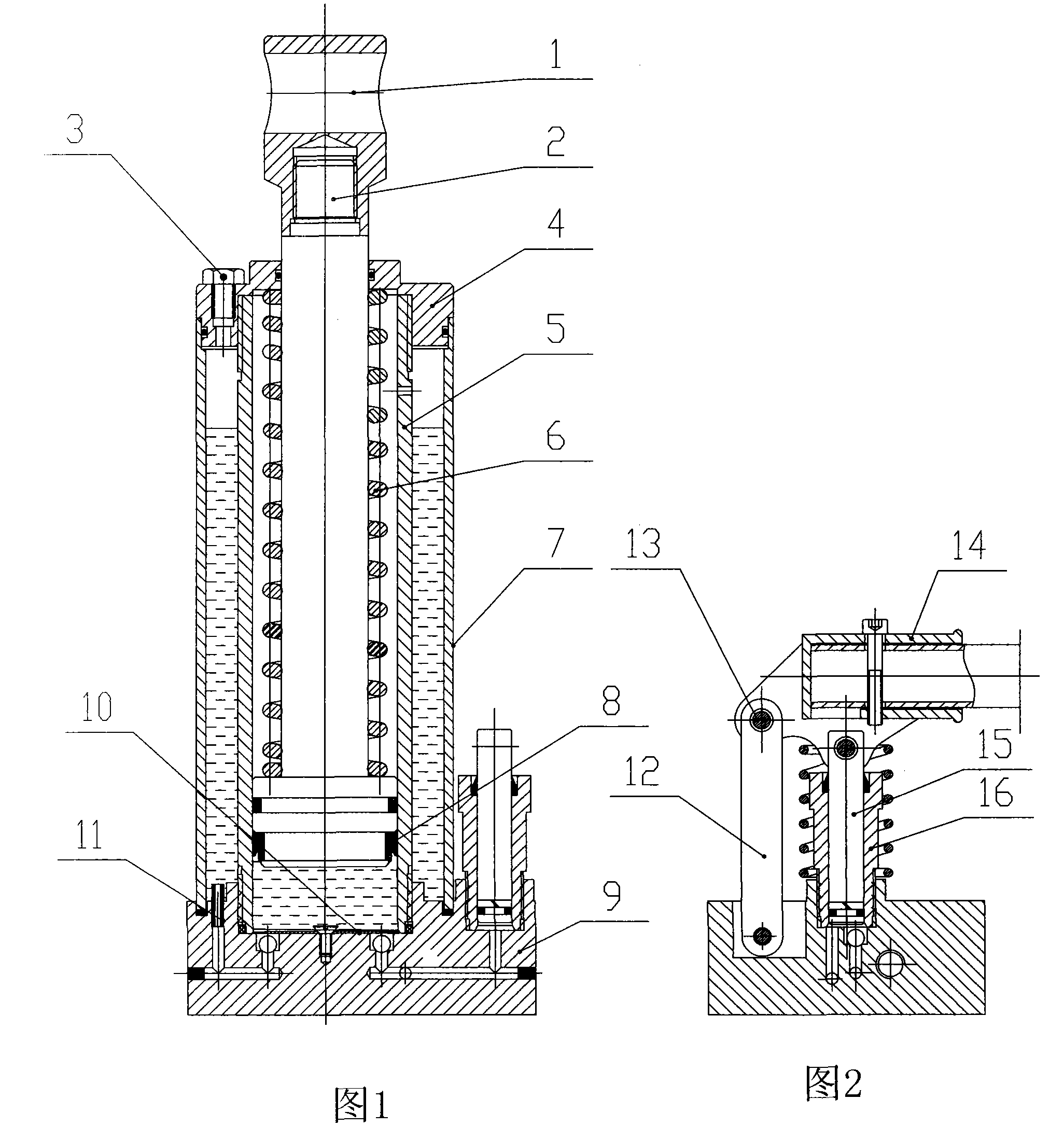

[0021] see figure 1 , figure 2 , image 3 , Figure 4 :

[0022] The oil pump invented this time is mainly composed of the following structures: hydraulic plug 1, piston 2, ventilation screw 3, top cover 4, cylinder body 5, compression spring 6, cylinder body 7, sealing ring 8, base 9, pressure plate 10, plastic soft Pipe 11, pole 12, pin 13, handle 14, small piston 15, pump body 16,

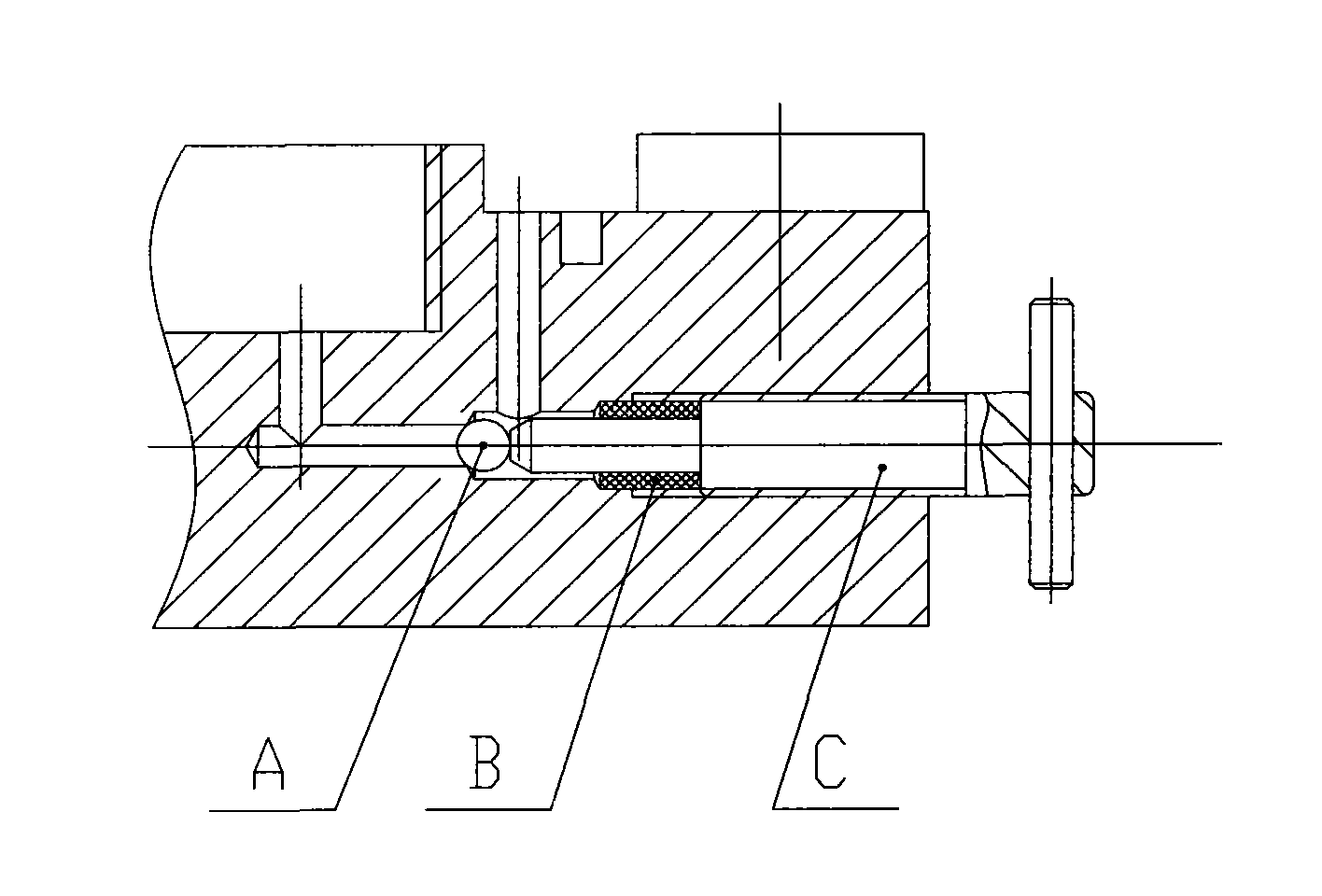

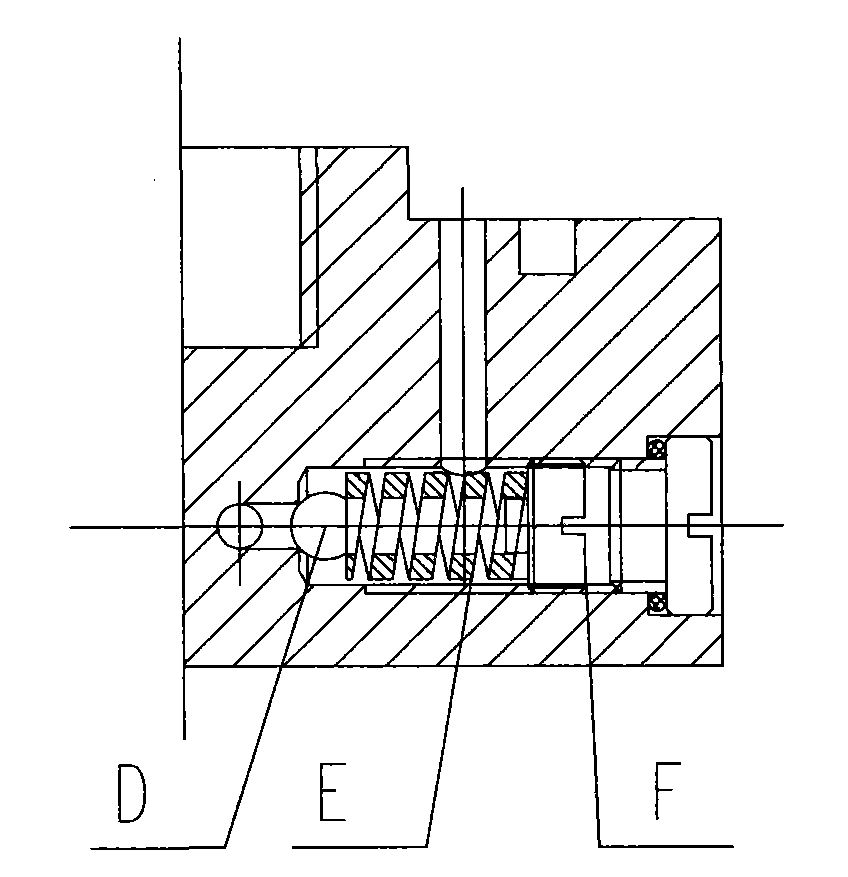

[0023] image 3 oil return circuit and Figure 4 The pressure regulating oil circuit, as well as other seals and standard parts.

[0024] The oil return route is composed of A. steel ball, B. sealing sleeve, and C. jacking screw, and the jacking screw passes through the sealing sleeve to top the steel ball.

[0025] The pressure regulating oil is composed of D. steel ball E. rectangular compression spring F. adjustment screw, and the adjustment screw, rectangular compression sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com