Construction method of cast-in-situ oblique arc-suspended concrete shear wall

A technology for concrete shear walls and construction methods, which is applied to the preparation of walls, formwork/formwork/work frames, and building components on site, and can solve the problem of complex design and installation of formwork and its supports, steel formwork and horizontal corrugation. Low utilization rate, difficulty in concrete pouring construction and other problems, to achieve the effect of easy promotion, fast construction process, simple and fast operation procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

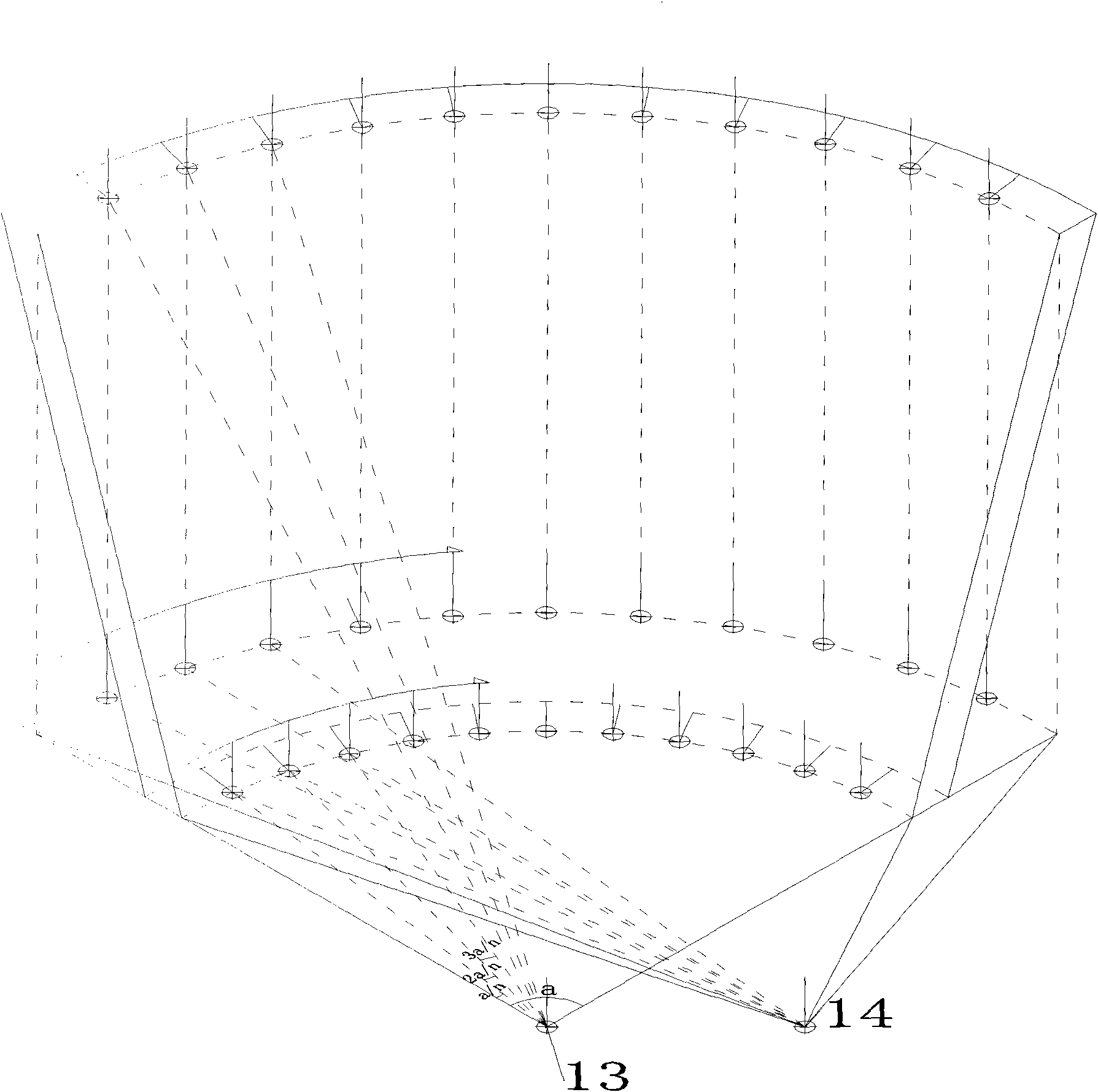

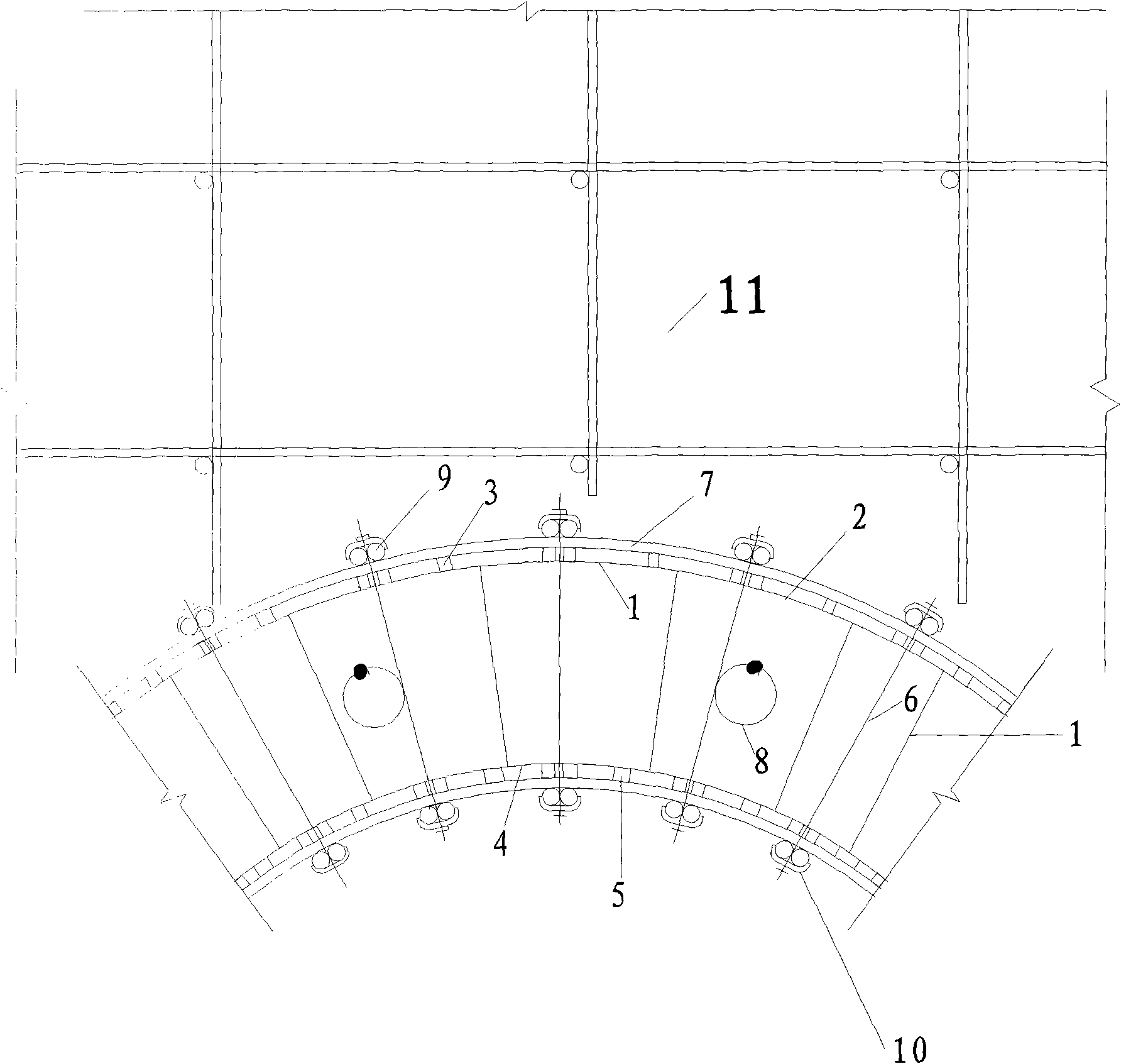

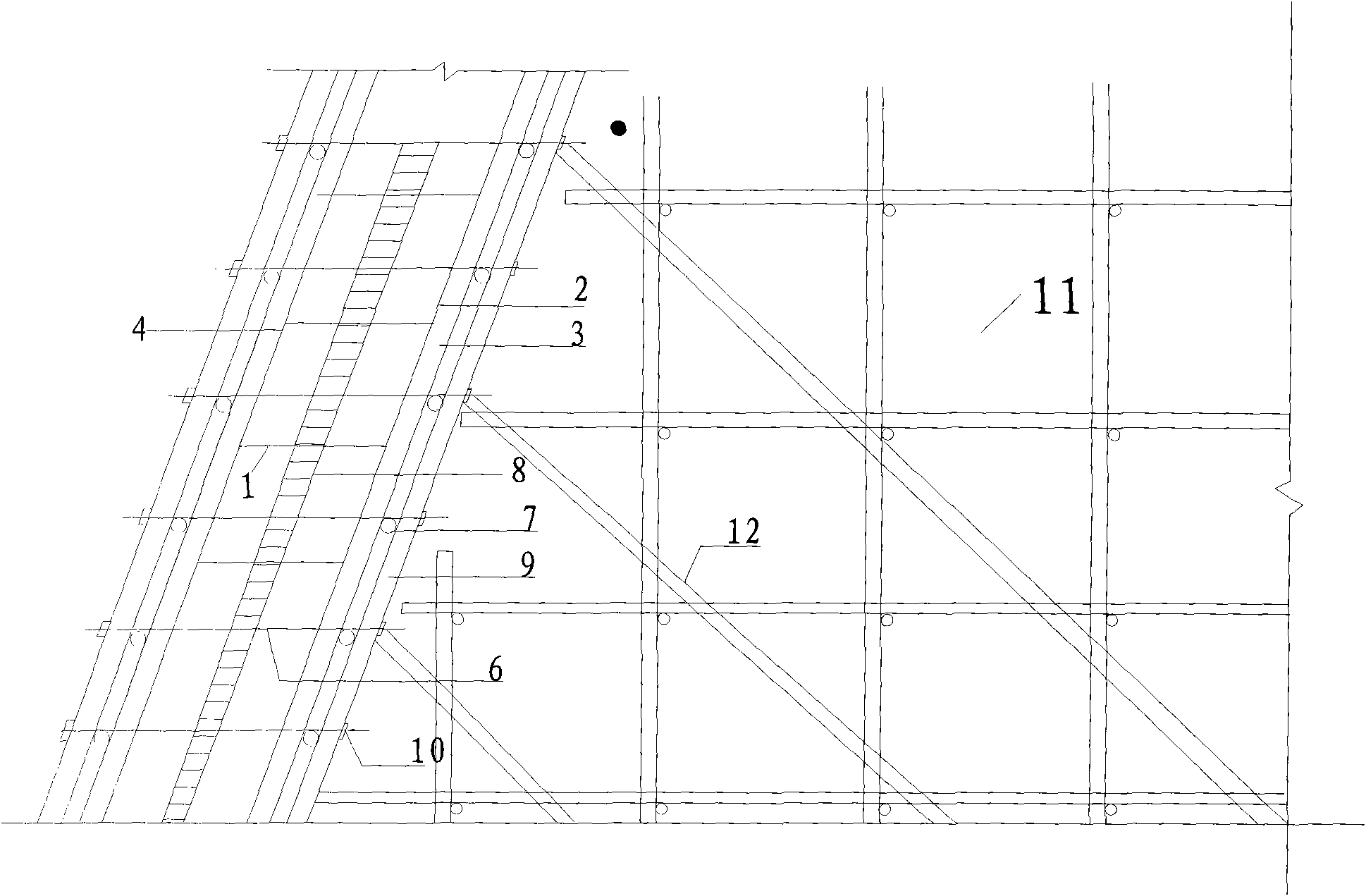

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0022] The construction method of the cast-in-place inclined cantilevered arc concrete shear wall works in the following principles: use CAD software and a total station to perform projection positioning of the outer edge of the inner and outer arc formwork at the foot of the inclined cantilevered arc concrete shear wall, and the outer edge of the inner and outer arc formwork at the top of the wall, and the inner and outer arcs Use threaded steel as a circular arc to position ribs and control the radian. The vibrating rod guide cage is installed in the shear wall to facilitate concrete vibration,

[0023] A method for the construction of cast-in-situ inclined hanging arc concrete shear walls, the specific steps of which are:

[0024] 1. Using CAD software, divide the projection of the outer edge of the inner and outer arc formwork at the foot of the inclined suspensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com