Gear with epicycloid-shaped tooth trace

A technology of epicycloids and gears, applied to components with teeth, belts/chains/gears, portable lifting devices, etc., can solve the problems of increasing friction loss of transmission devices, generating axial thrust, etc., and achieve long service life , small meshing impact and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

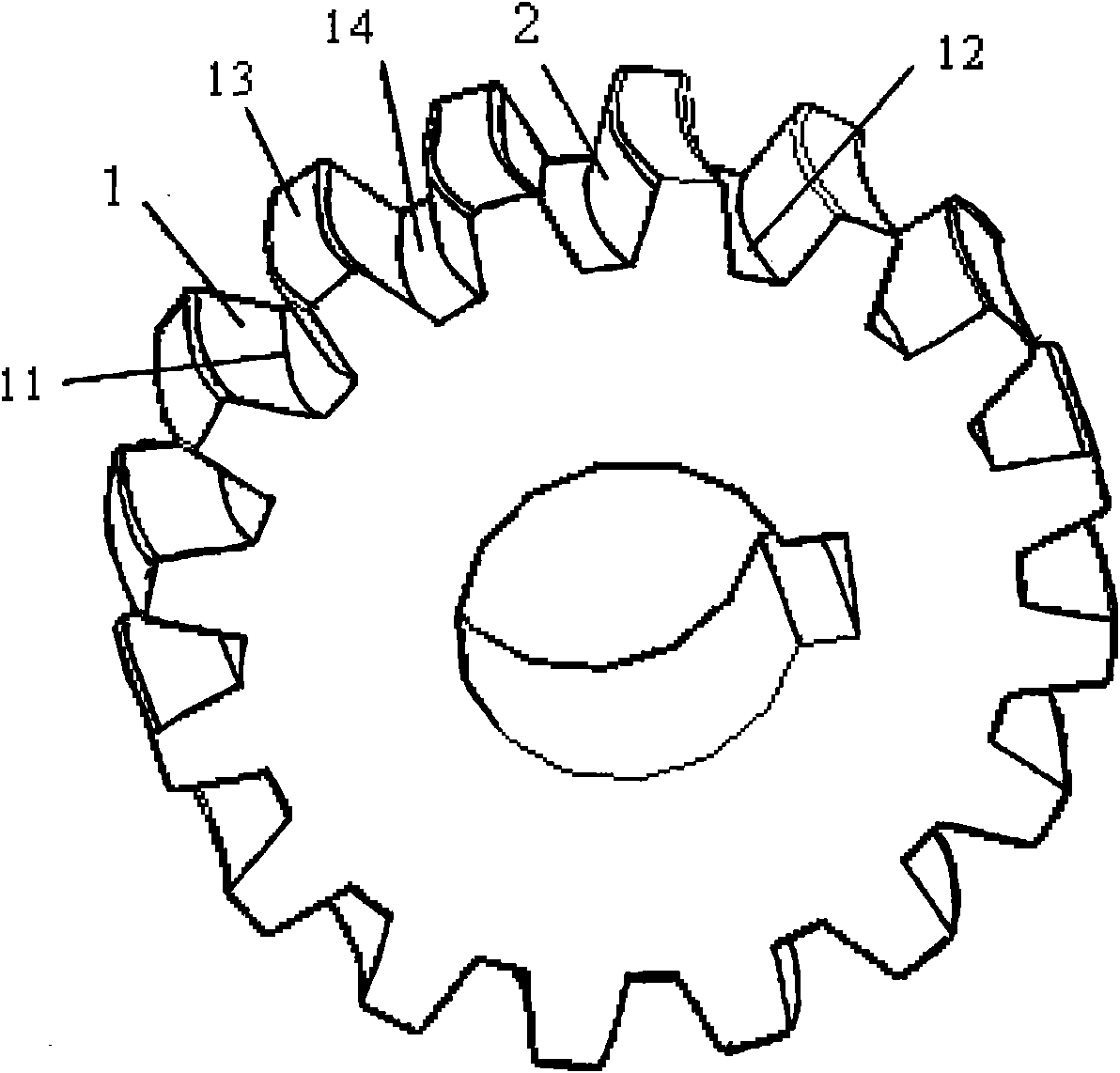

[0017] Such as figure 1 , the gear of the present invention is composed of a convex tooth surface, a concave tooth surface, a dedendum cylindrical surface, and an addendum cylindrical surface. Both are long-length epicycloids.

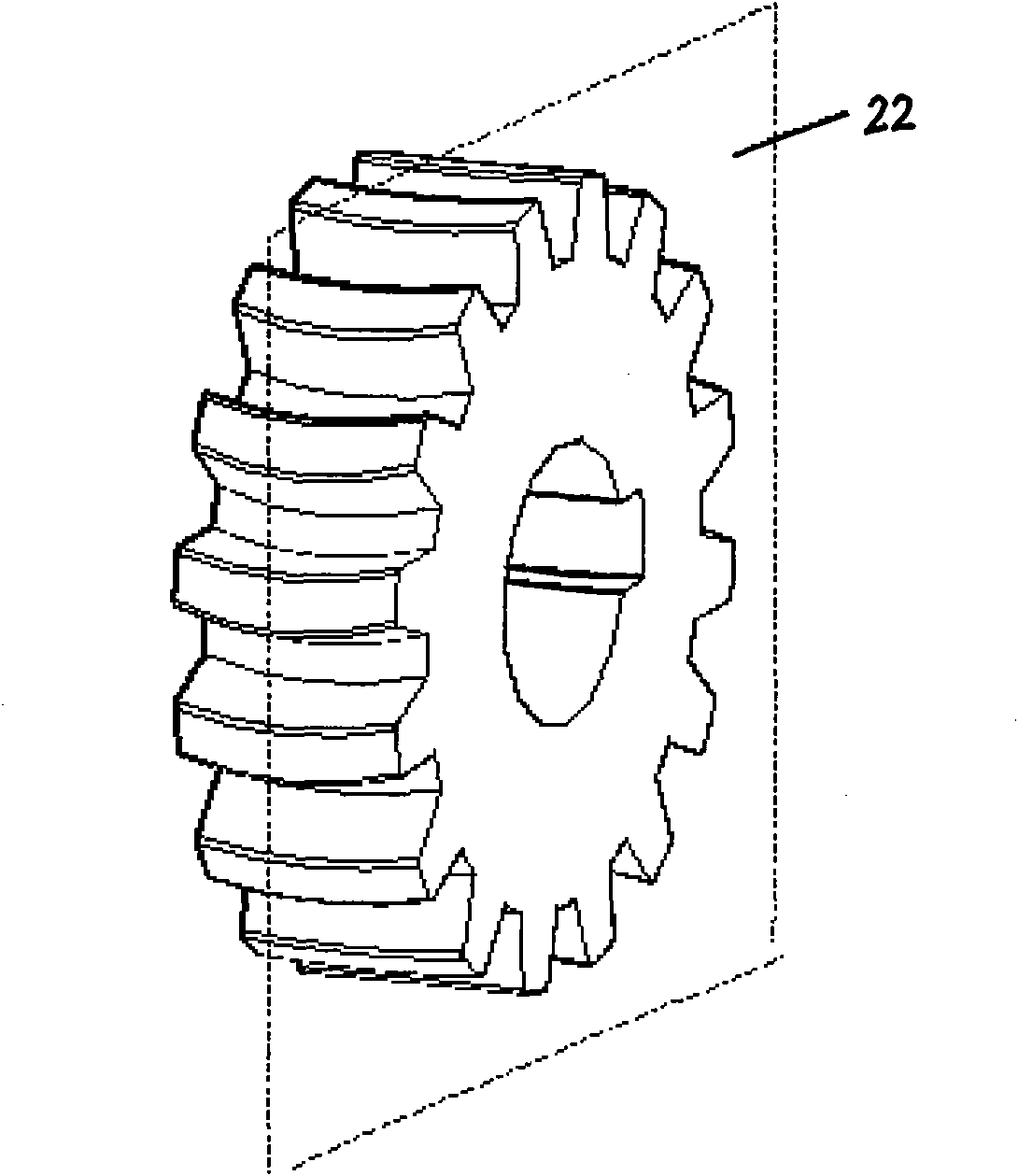

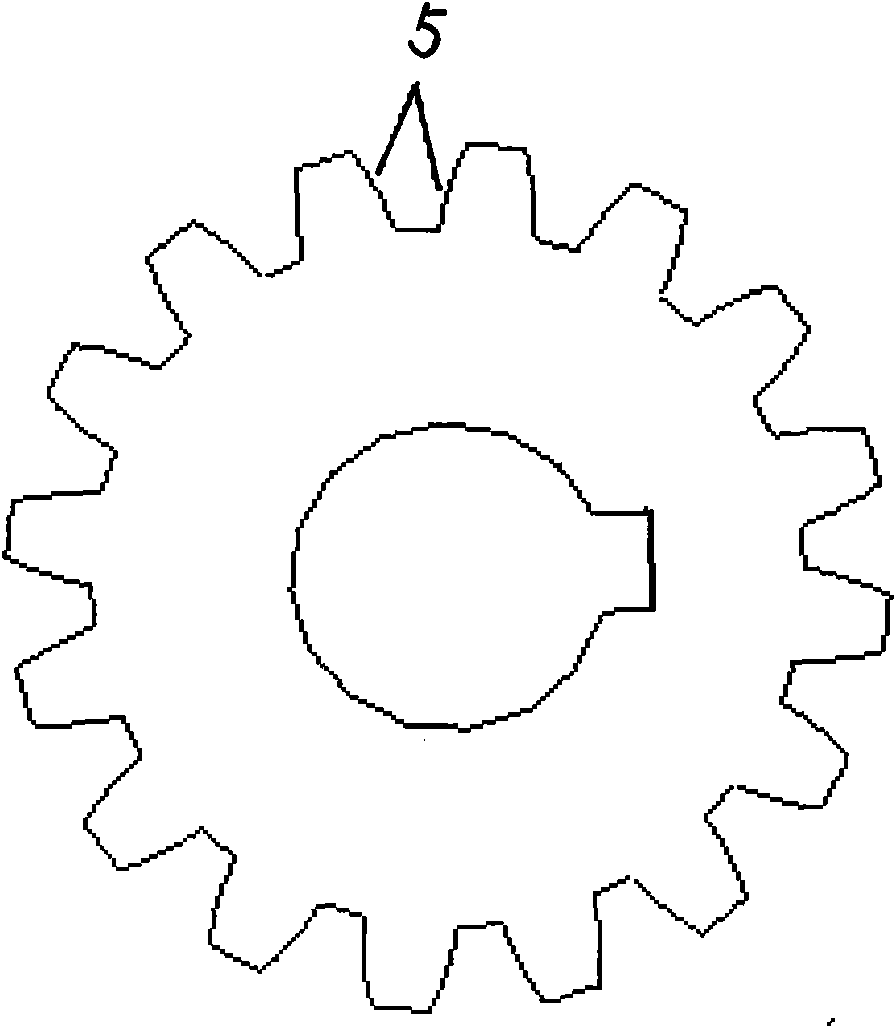

[0018] see figure 2 and image 3 , in the central section in the tooth width direction, the tooth profile curve of each tooth of the present invention is an involute, and the tooth profile curve of each tooth of the cylindrical gear meshed with the present invention is also an involute. That is, in the above-mentioned central section, the meshing between the two is equivalent to the meshing between the traditional involute gears, so it has a constant transmission ratio, and the central section can be used as a benchmark for calculating the geometric dimensions of the gear transmission. The convex tooth surface and the concave tooth surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com