Bi-pitch and variable-pitch tooth-shaped conveyer chain

A conveyor chain and variable pitch technology, which is applied in the field of conveyor chains, can solve the problems of toothed chain conveyor chains, such as heavy weight, serious chain jamming, and high processing costs, so as to improve service life, reduce polygonal effects, and reduce meshing impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

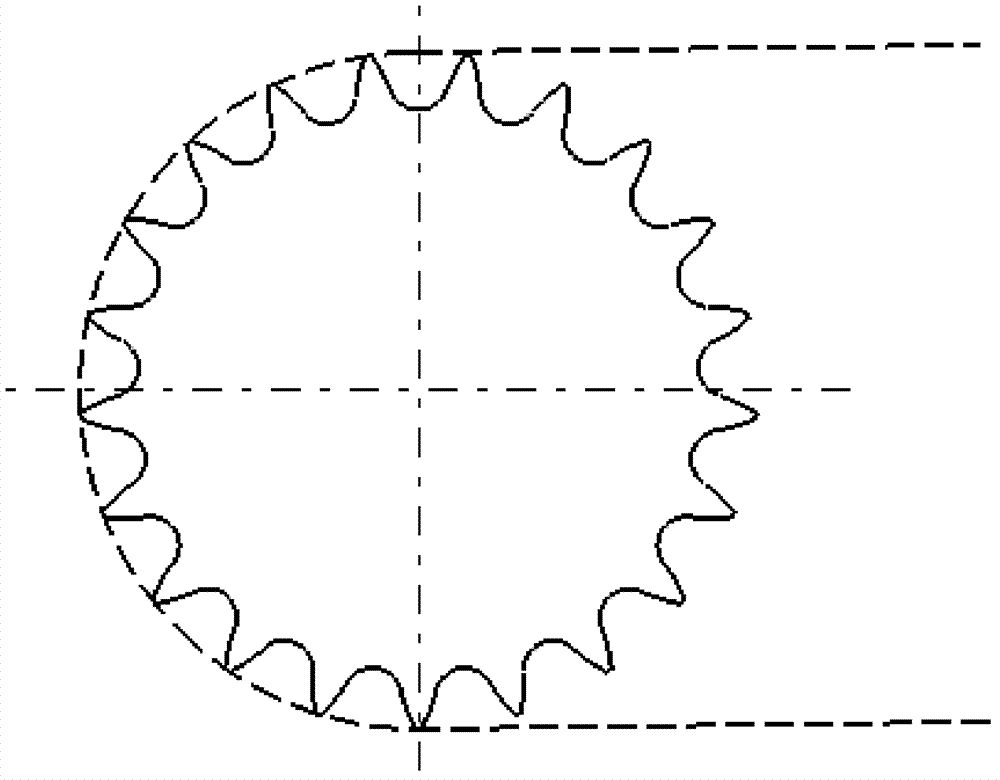

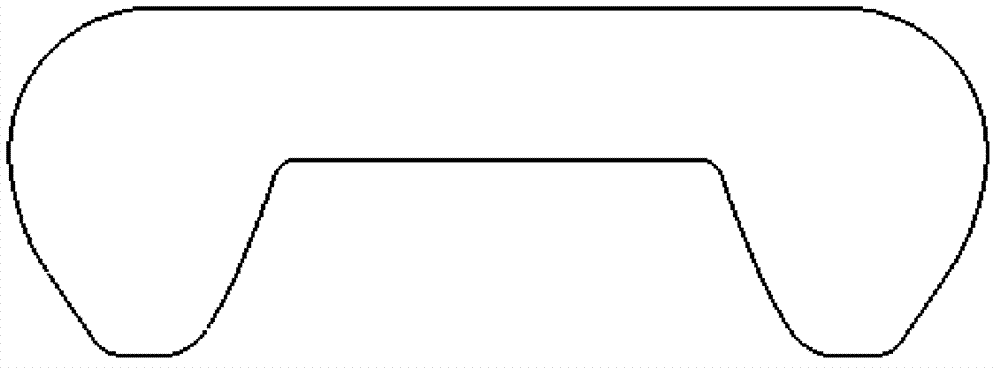

[0044] In one embodiment of the present invention, among the three tooth profiles of the chain plate, the inner tooth profiles of the two teeth at both ends are concave-convex curves, the outer tooth profiles are straight lines, and the tooth profiles of the middle teeth are all straight lines.

[0045] In one embodiment of the present invention, the chain plate has a double pitch on the meshing line with the sprocket, and the difference between the hole center distance and twice the pitch of the sprocket meshing with it is approximately equal to 2P( 1-cos(π / Z)).

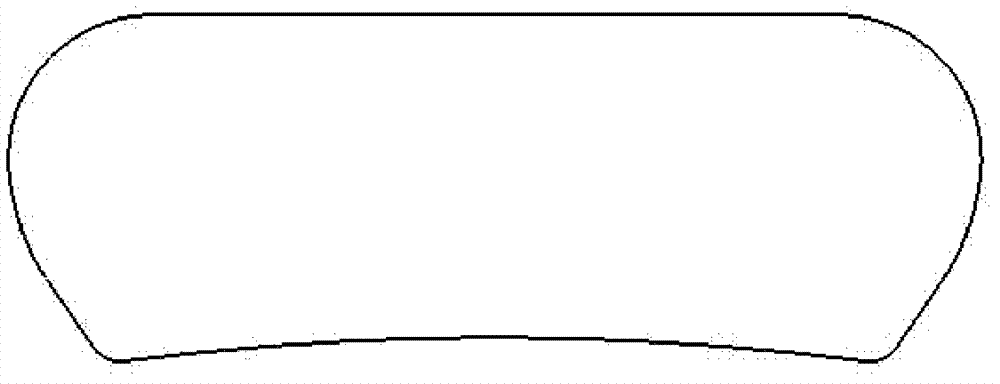

[0046] In one embodiment of the present invention, the two ends of the chain plate have two pin holes of different sizes and shapes, wherein the smaller pin hole has an interference fit with the special-shaped pin shaft, and the larger pin hole has an interference fit with the special-shaped pin shaft. The rolling engagement of the pin shaft and the effective profile of the pin shaft meshing is a curve that makes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com