Optimization method of natural distortion micro-modification for helical gear grinding with worm grinding wheel

A technology of worm grinding wheel and helical gear, which is applied in the field of mechanical structure, can solve the problems affecting the acoustic and vibration roughness of the gearbox, the roughness performance, the inability to control or compensate the distortion of the tooth surface of the grinding tooth, and the reduction of meshing transmission accuracy, etc., to achieve improvement Effects of gear load-carrying performance, improvement of NVH level, and reduction of tooth crowning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

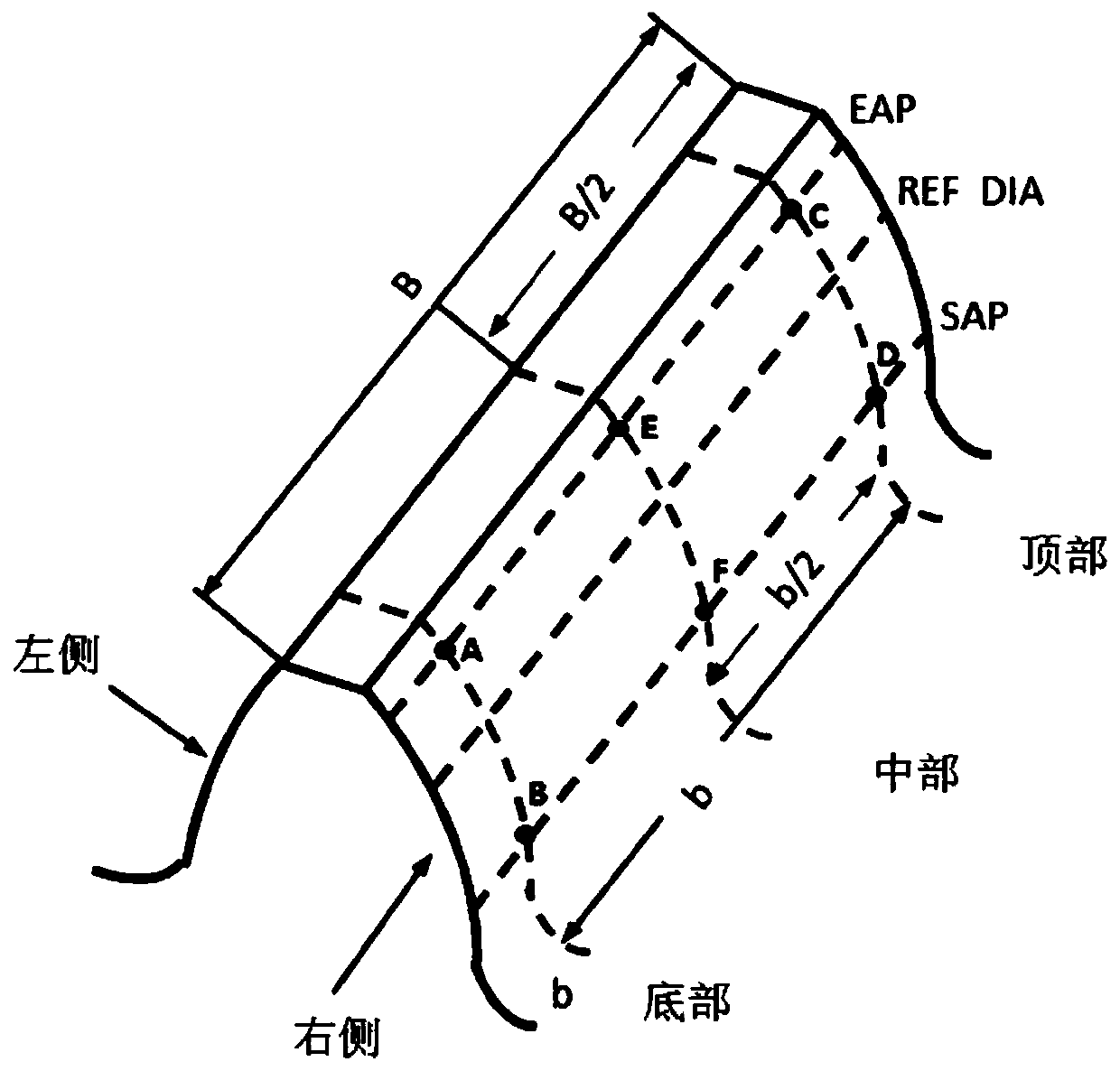

[0033] Such as Figure 6 As shown, this embodiment specifically includes the following steps:

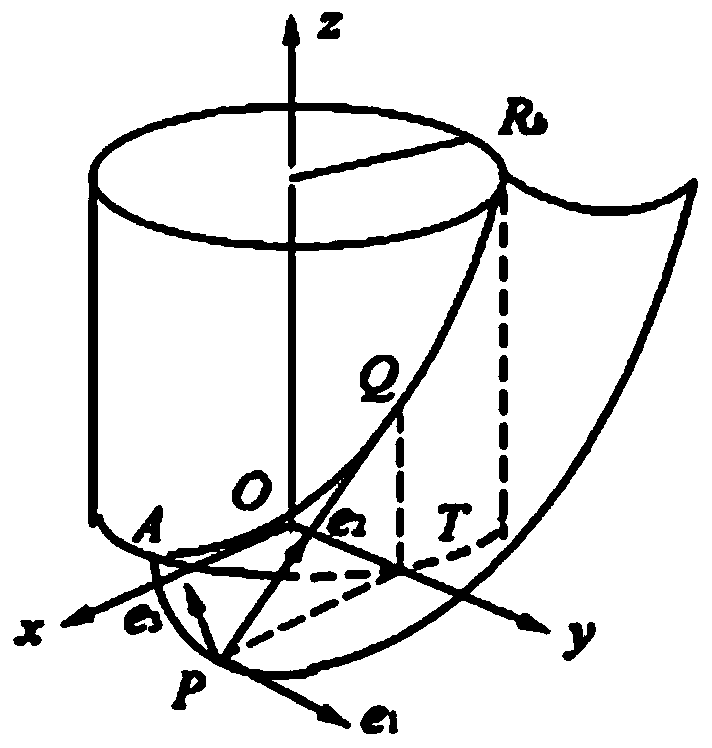

[0034] Construct the meshing model of helical gears with worm grinding wheel, derive the contact trace equation, select the evaluation range of tooth shape and direction, establish the tooth surface distortion model, and obtain the tooth profile angle deviation under the natural distortion of worm grinding wheel grinding helical gears Gear angle deviation value details as follows:

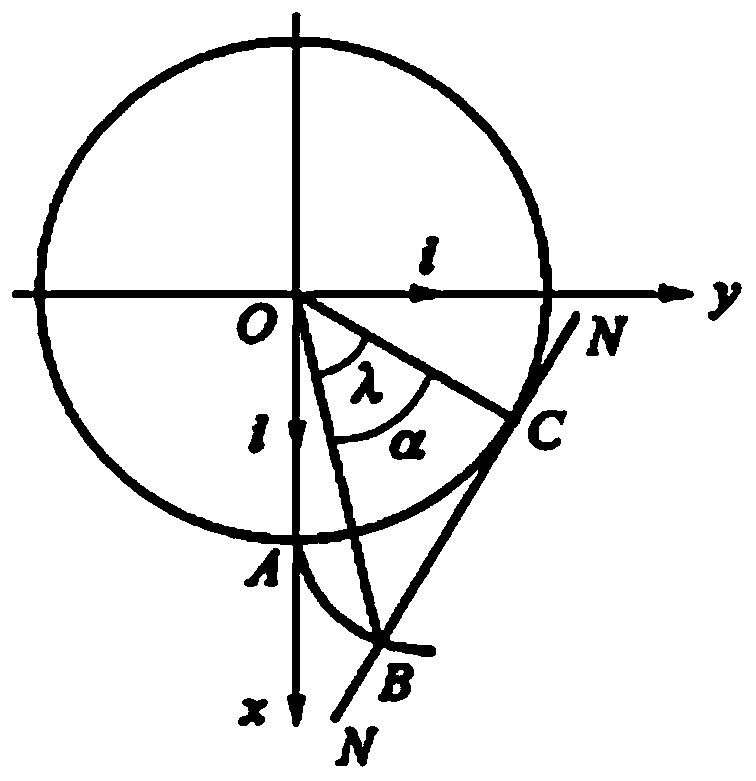

[0035] The contact trace on the helical profile surface can be regarded as a collection of points satisfying the contact condition on the involute helical surface. Therefore, in order to derive the contact trace equation, it is necessary to give the involute helicoid equation and contact conditions first. where: r b is the radius of the base circle, r p is the radius of the pitch circle, r i is the radius of any circle on the gear, β b is the base circle helix angle, β p is the pitch circle hel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com