Complex-terrain long-distance iron ore concentrate conveying pipeline multi-level demagnetizing system

A complex terrain, long-distance technology, applied in the direction of pipeline systems, magnetic objects, electrical components, etc., can solve the problems of pipeline blockage, affecting normal production, etc., achieve the effect of improving service life and avoiding magnetic agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

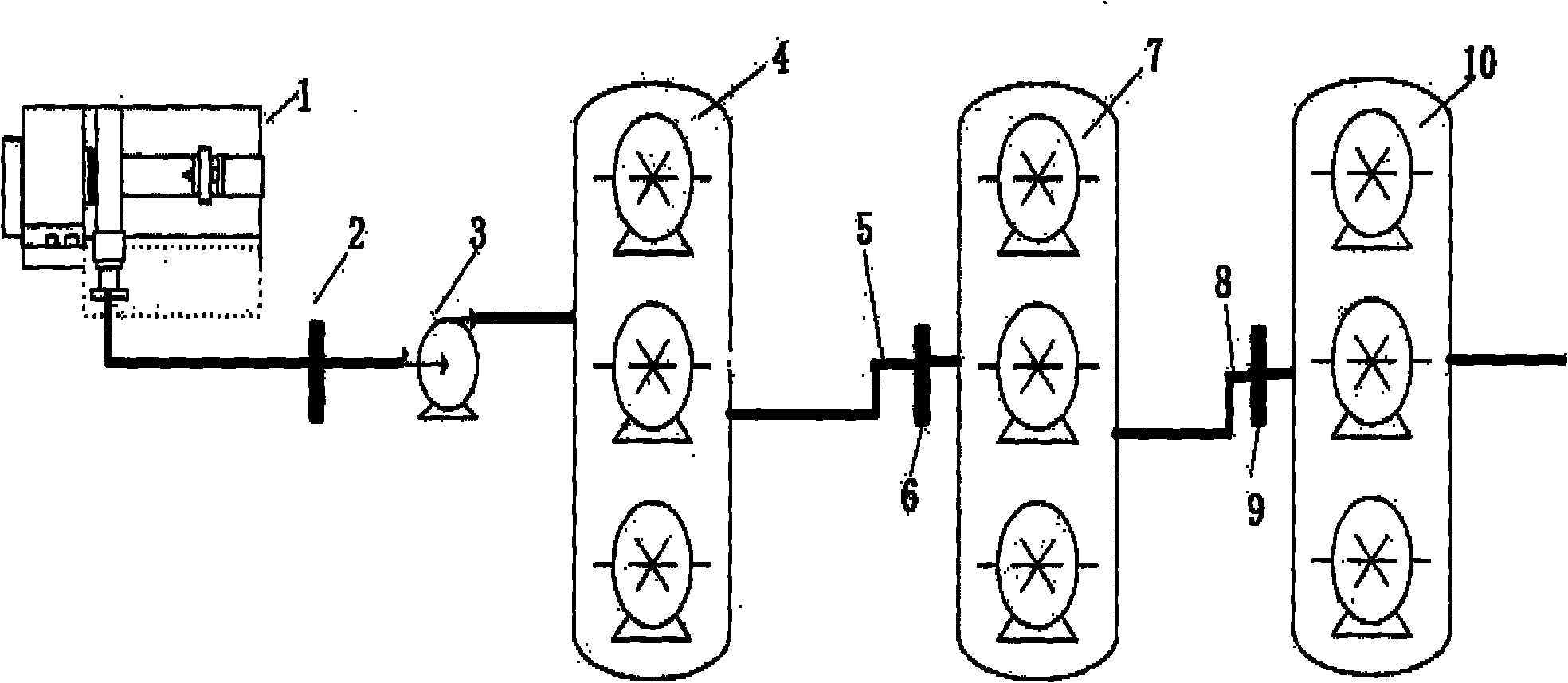

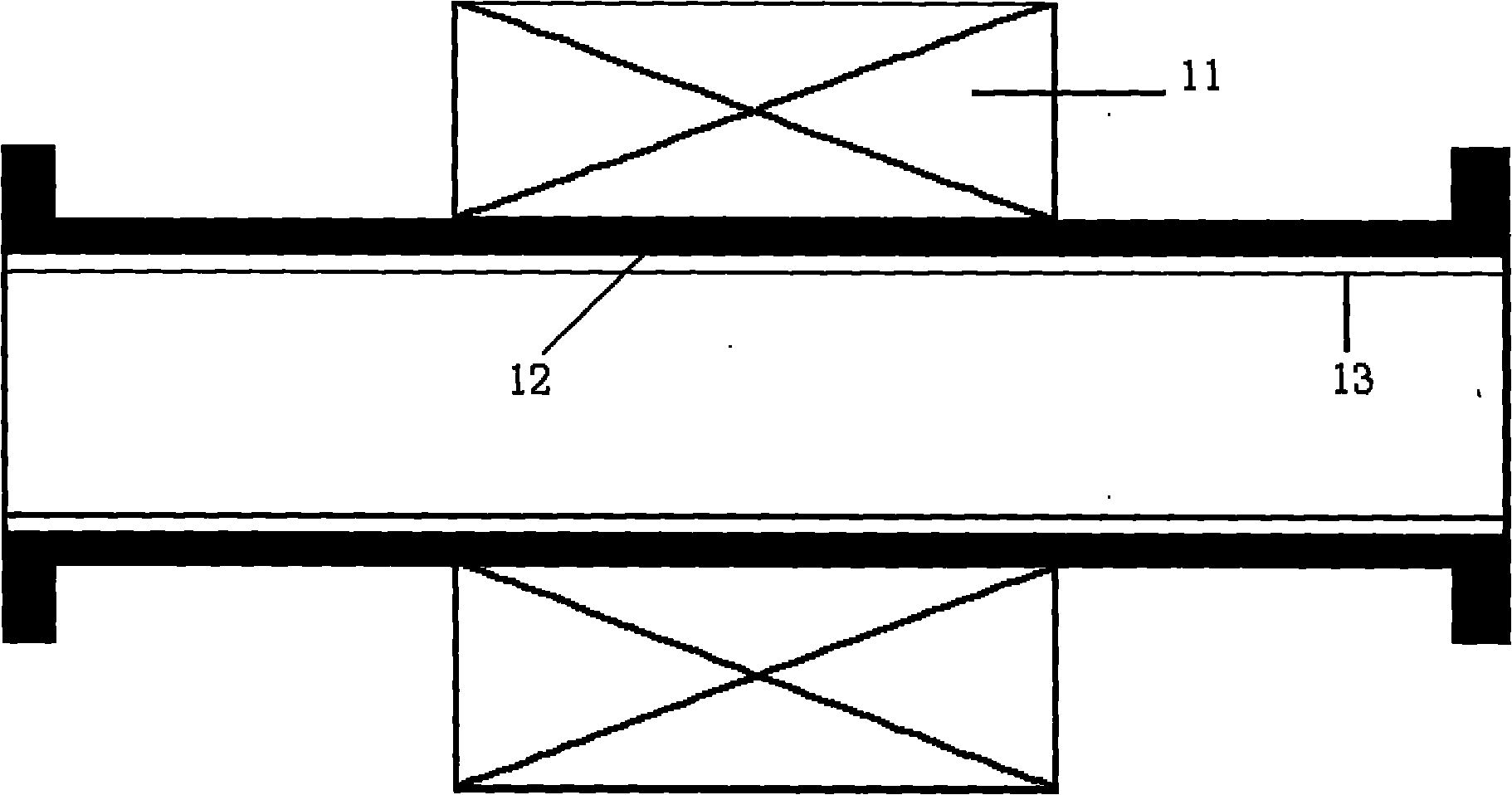

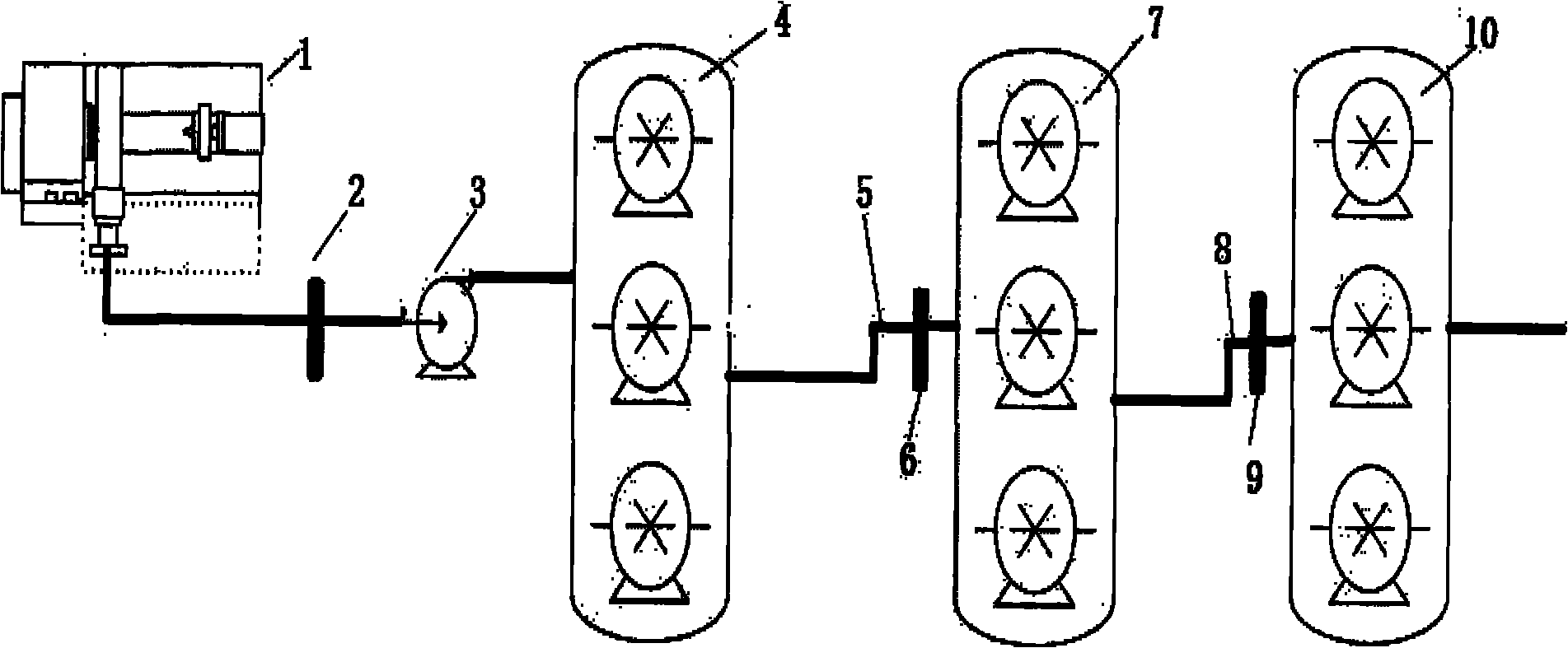

[0016] Combine below figure 1 and figure 2 , the present invention is further described:

[0017] A multi-stage demagnetization system for long-distance iron ore concentrate slurry pipelines with complex terrain, including a concentrator 1, an underflow pump 3 and multiple pump stations 4, 7, 10, the output end of the concentrator 1 is connected to the underflow pump 3 The input end of the underflow pump 3 is connected through a pipeline, and the output end of the underflow pump 3 is connected to the multiple pumping stations 4, 7, 10 through pipelines in turn. On the connecting pipeline between the thickener 1 and the underflow pump 3, Demagnetizer 2.

[0018] Demagnetizers 6 and 9 are also provided on the pipelines connected to two adjacent pumping stations. The demagnetizers 6 and 9 provided on the pipelines connected to two adjacent pumping stations are located on the inlet pipelines of the pumping stations.

[0019] Such as figure 1 As shown, the multiple pumping st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com