Silicon rubber insulation wind power motor leading and connecting flexible cable and preparation method thereof

A technology of silicone rubber insulation and silicone rubber insulation layer, applied in the direction of insulated cables, cable/conductor manufacturing, insulated conductors, etc., can solve the problem of easy scratches and cracks on the silicone rubber insulation layer, damage to the silicone rubber insulation layer, and poor mechanical properties and other issues, to achieve the effect of wide temperature range, improved wear resistance, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

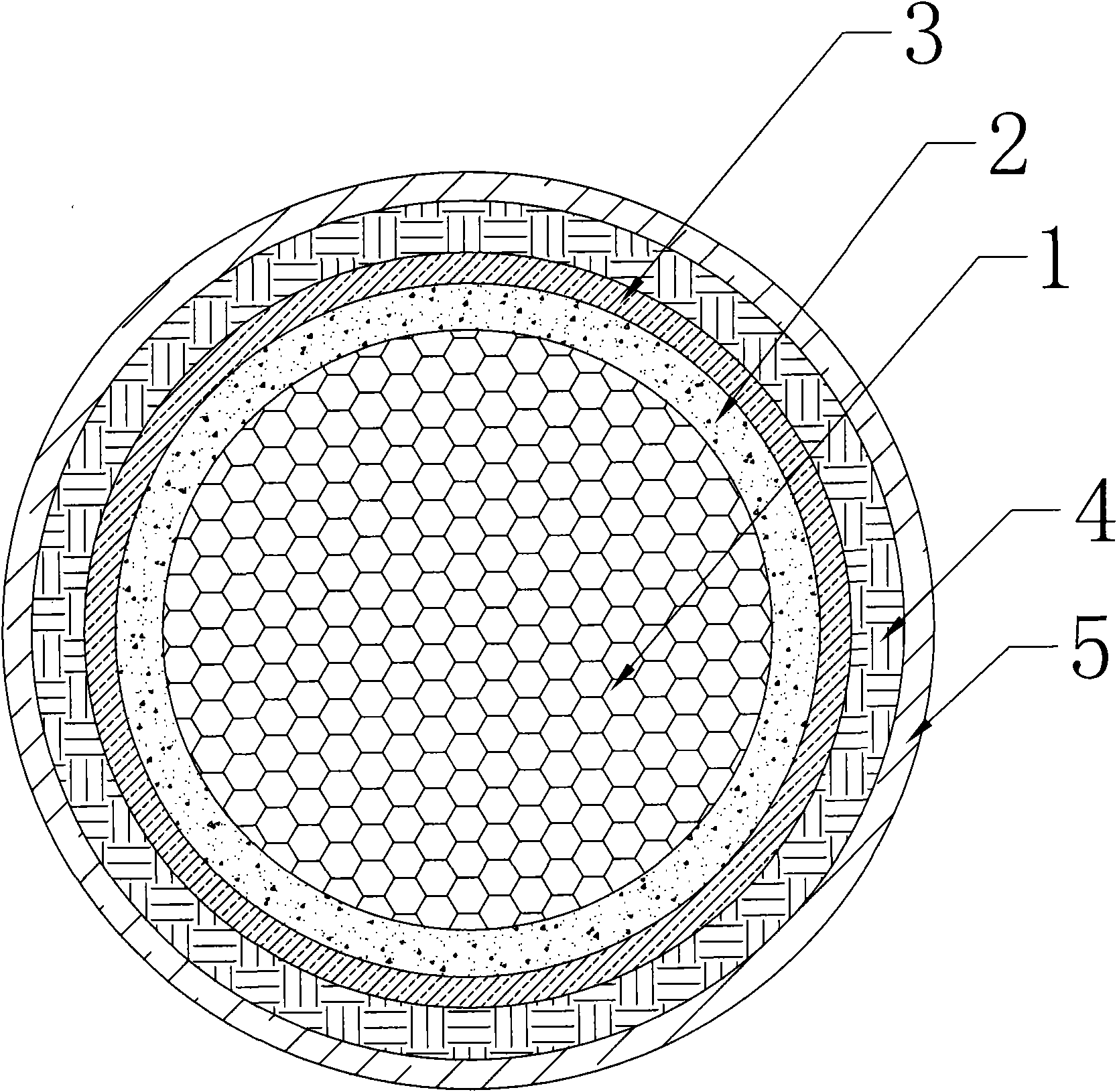

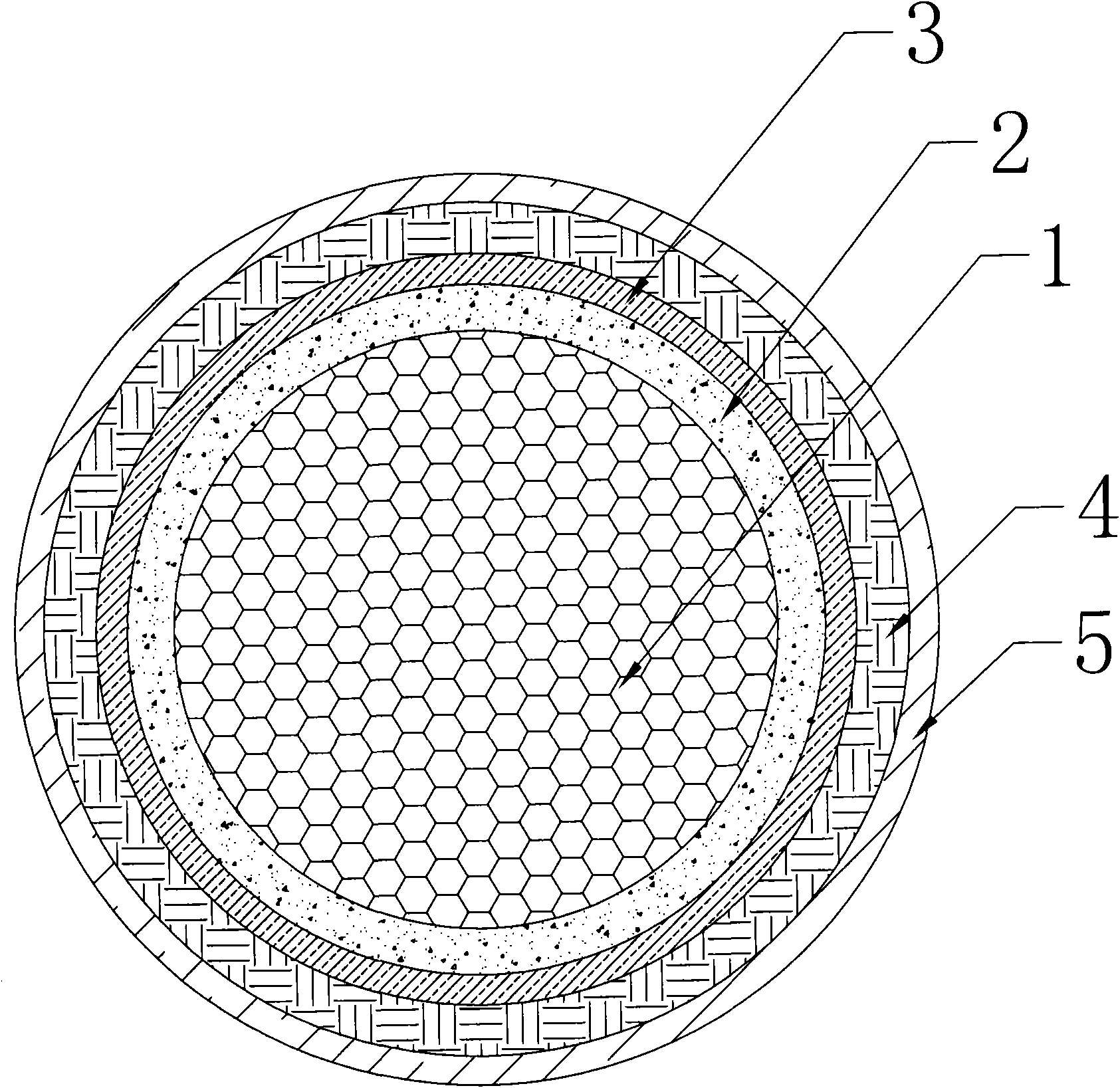

[0016] Example 1, (1), the outer surface of the silicone rubber cable is wrapped with polyester film, the thickness of the polyester film is 0.25mm, so that it produces a layer of isolation layer; the silicone rubber cable consists of 950 copper wires of Φ0.40mm Copper conductor and silicone rubber insulation layer extruded outside the copper conductor;

[0017] (2), put the 4500D aramid fiber into 24 braided wraps on the polyester film surface of the cable after wrapping the polyester film, so that the weaving density of the aramid fiber on the polyester film reaches more than 90%;

[0018] (3) The surface of the aramid fiber of the cable prepared in step (2) is sprayed with a layer of impregnated insulating resin, and then baked at 100°C for 2 minutes to cure the impregnated insulating resin, and the finished silicone rubber insulated wind power motor leads soft The cable; the impregnated insulating resin is grade F impregnated insulating resin 319-5F produced by Jiangyin De...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com