Self-making device of whole rotor winding of high-power generator

An integral rotor and generator technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems that the true shaft rotor core cannot be wound with coils, and the rotor core of more than 1 ton cannot be wound, so as to achieve weight reduction. Reduce the clamping time, the effect of uniform speed ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

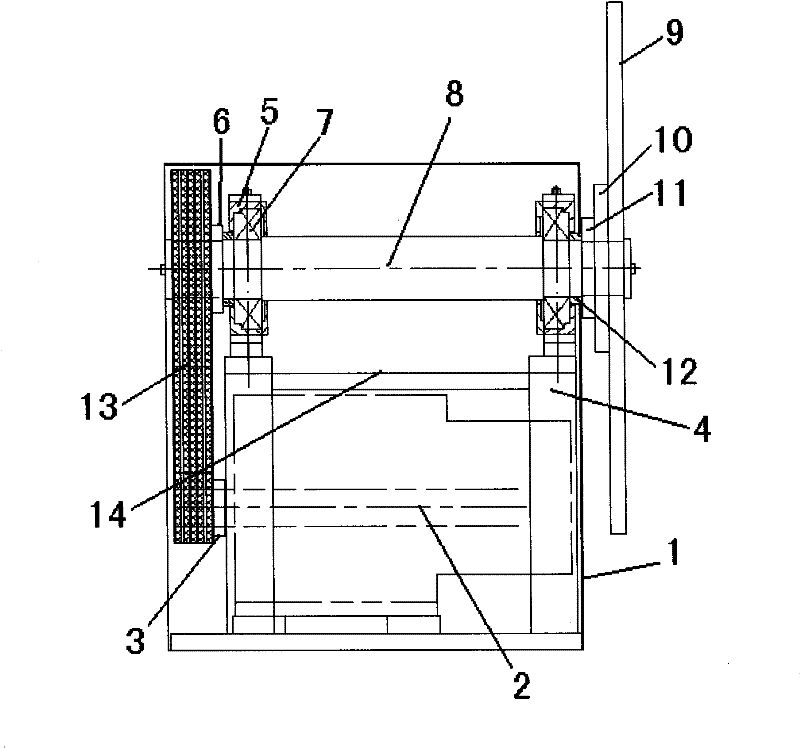

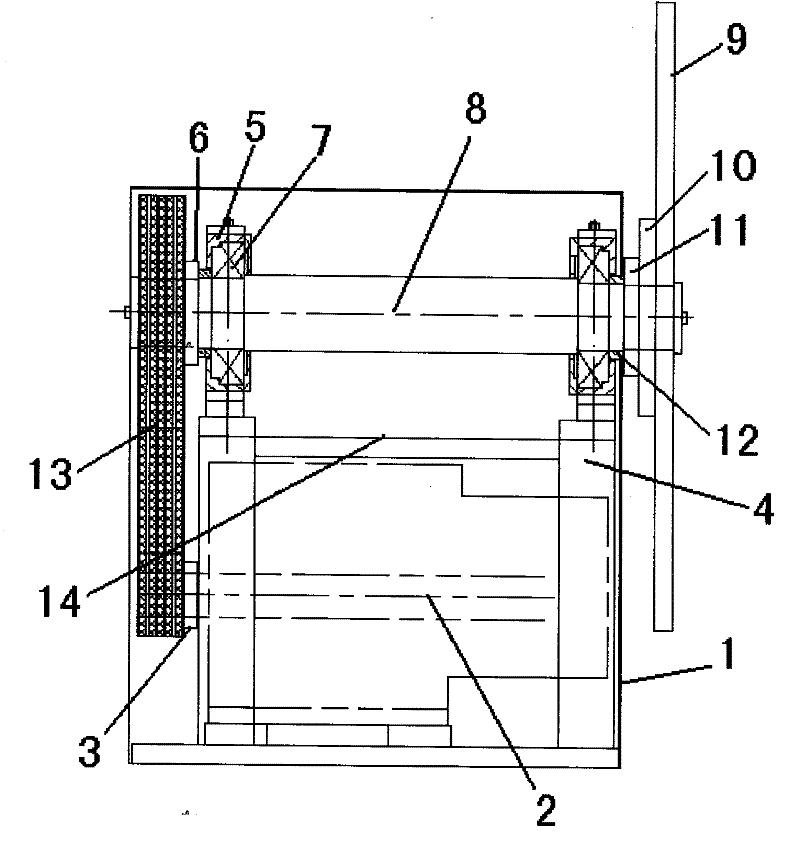

[0009] Such as figure 1 As shown, the present invention is realized in this way, the bottom end of the bracket 1 is fixedly connected with a cycloid pinwheel reducer 2, the output shaft of the cycloid pinwheel reducer 2 is coaxially connected with a small pulley 3, and both sides of the bracket 1 Each support frame 4 is provided with a bearing seat 5 fixedly connected to the two support frames 4, a single row tapered roller bearing 7 is connected in the bearing seat 5, and a rotating shaft 8 is connected between the two single row tapered roller bearings 7 One end of 8 is connected to the long arm 9, C-type ordinary flat key 10, coupling plate 11 and bearing retainer ring 12 in sequence from the outside to the inside. The other end of the rotating shaft 8 is connected to a large pulley 6, which is connected to the small pulley through a belt 13. 3. A screw 14 is connected between the supporting frames 4. When working, use a crane to lift the rotor core so that the shaft extens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com