Magnetic engine

An engine and magnetic technology, applied in the direction of generators/motors, electrical components, etc., can solve the problems of serious pollution and high energy consumption, and achieve the effect of wide application, convenient installation and processing, and easy replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

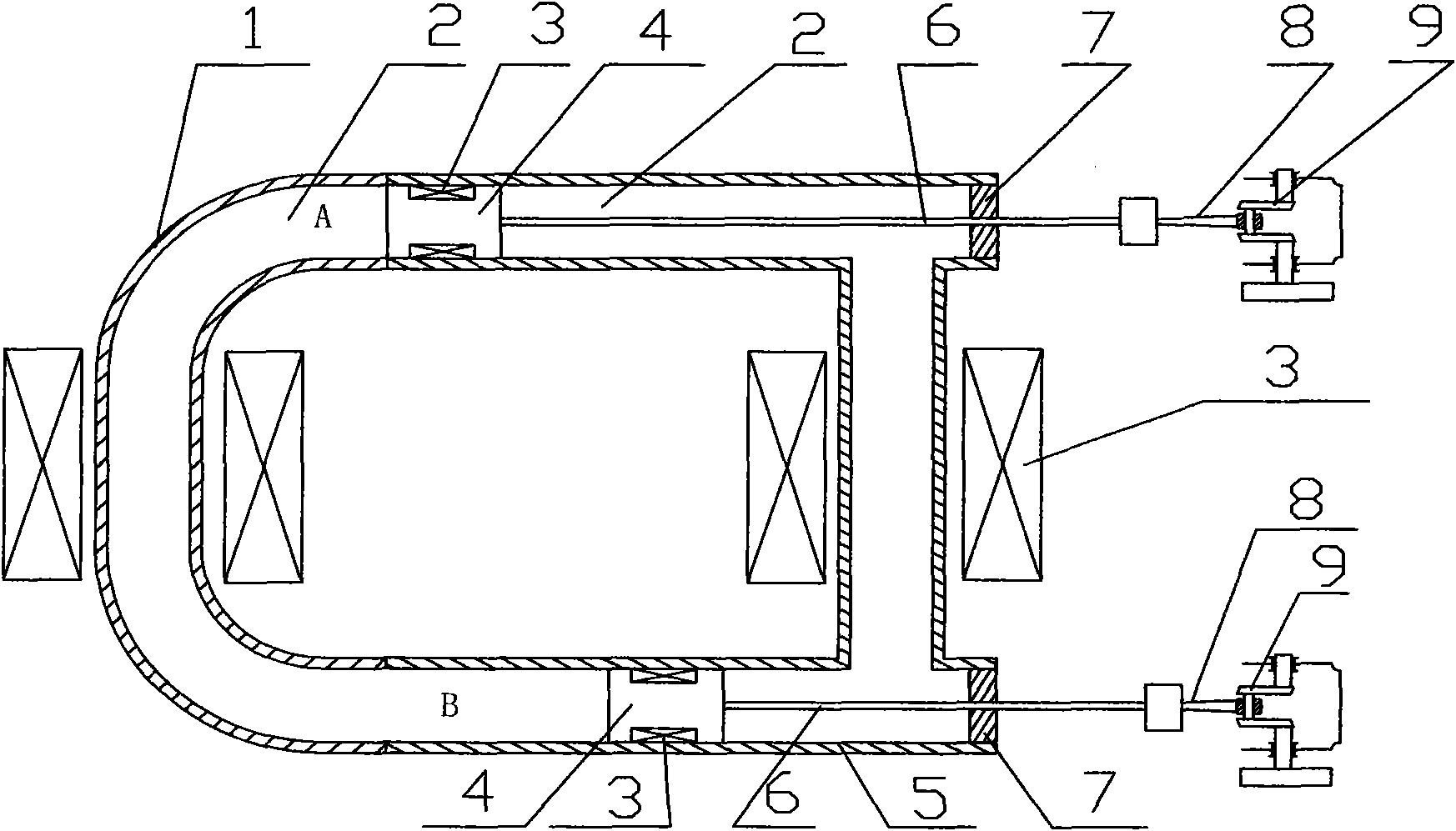

[0071] Embodiment 1: a kind of magnetic motor (referring to attached figure 1 ), including a U-shaped pipe 1, an I-shaped pipe 5, two pistons 4 and an output shaft 6 connected to the piston 4, two ports of the U-shaped pipe 1 are respectively connected with two ports on one side of the I-shaped pipe 5, and U The straight section in the middle of the tube 5 is wrapped with a coil 3 and the coil 3 is fixed; the straight section in the middle of the I-shaped tube 5 is wrapped with a coil 3 and fixed; the piston 4 is arranged between the I-shaped tube 5 and the U-shaped tube. The joint of the tube 1 is matched with the I-shaped tube 5, one end of the output shaft 6 is fixed in the middle of the corresponding end face of the piston 4, and the other end of the output shaft 6 passes through the through hole of the I-shaped tube 5 and is connected from the I-shaped tube 5. The other side protrudes from the port; the coil 3 is wrapped around the piston 4 with the moving direction of th...

Embodiment 2

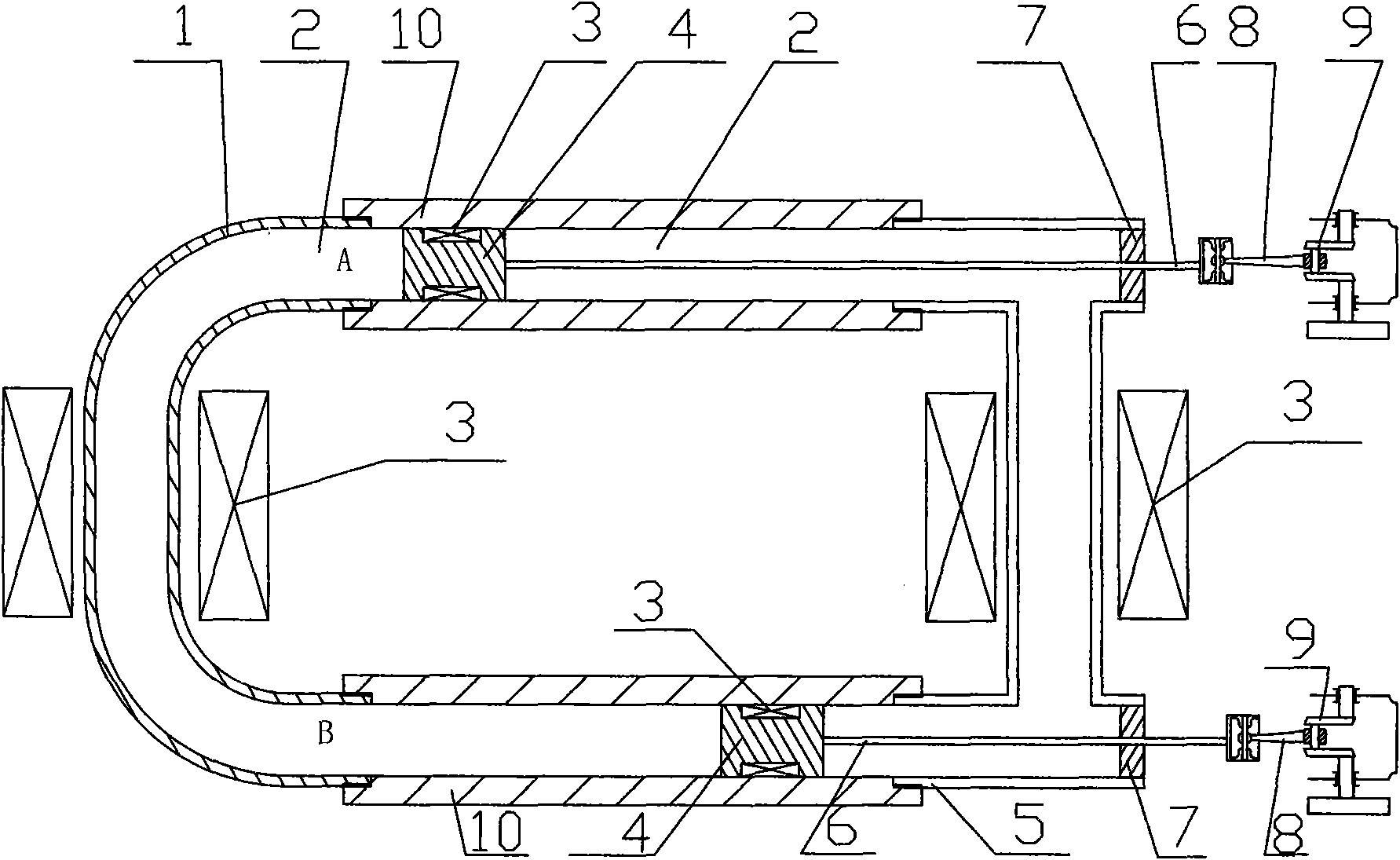

[0074] Embodiment 2: a kind of magnetic motor (referring to attached figure 2 ), its basic structure is the same as embodiment 1, and the difference is: the junction of U-shaped pipe 1 and I-shaped pipe 5 is provided with straight pipe 10, and the two ends of straight pipe 10 are connected with U-shaped pipe 1 and I-shaped pipe respectively. The type pipe 5 is threaded, the piston 4 is arranged in the straight pipe 10 and the piston 4 is matched with the straight pipe 10.

Embodiment 3

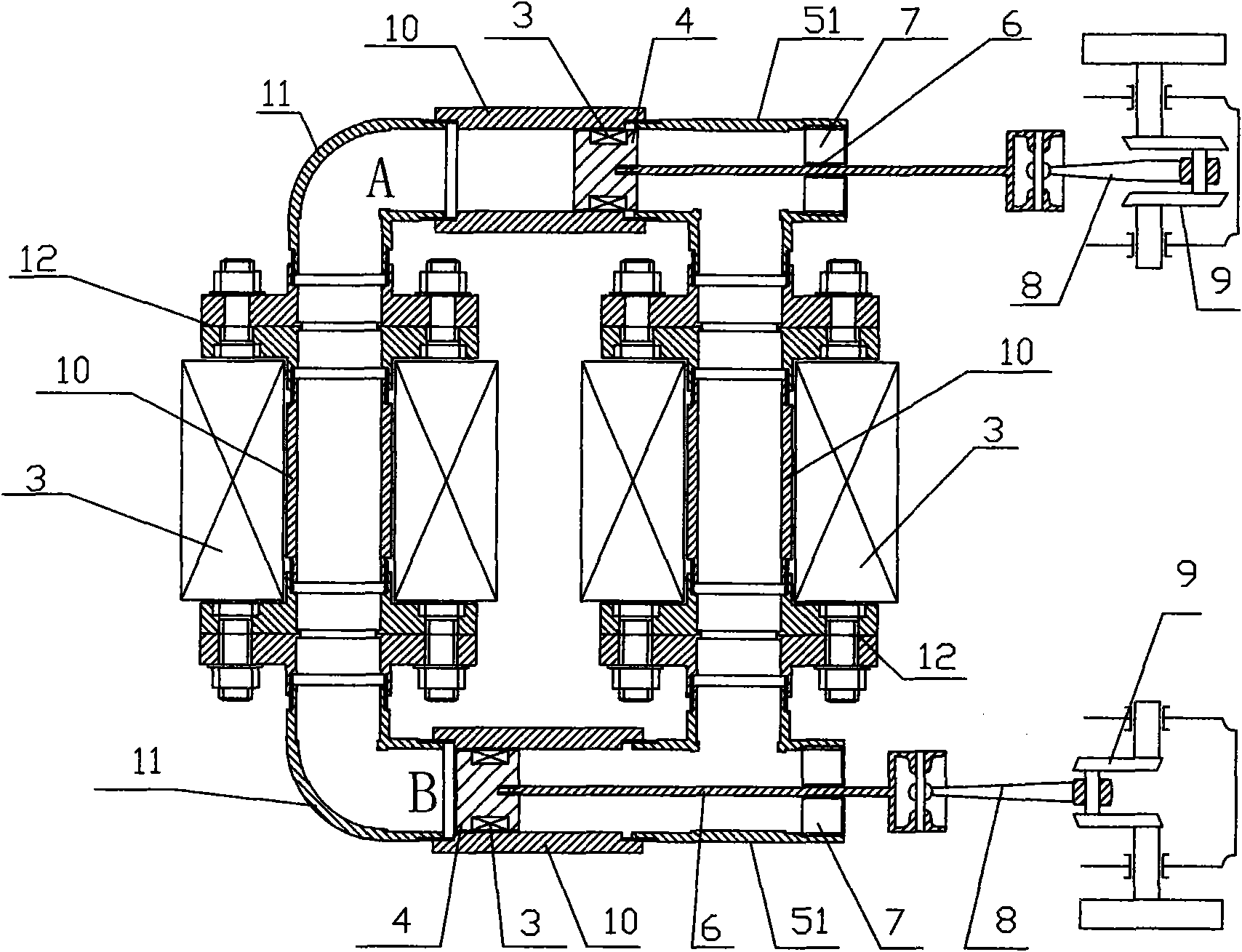

[0075] Embodiment 3: a kind of magnetic motor (referring to attached image 3 ), its basic structure is the same as that of Embodiment 2, and the difference is: U-shaped pipe 1 includes a straight pipe 10 and two 90-degree elbows 11, and the two ends of the straight pipe 10 are connected with the two 90-degree elbows 11 respectively. One end is threaded; the I-shaped pipe 5 includes two 90-degree tees 51 and a straight pipe 10, and the two ends of the straight pipe 10 are respectively threaded with one end of the two 90-degree tees 51; the U-shaped pipe 1 and the I-shaped Type pipe 5 all adopts combined structure. Flanges 12 are provided at the joints between the straight pipe 10 of the U-shaped pipe 1 and the two 90-degree elbows 11 of the U-shaped pipe 1, and the coil 3 outside the straight section of the U-shaped pipe 1 is fixed on the straight pipe through the flange 12. Tube 10 outside. A flange 12 is provided at the connection between the straight pipe 10 of the I-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com