Material diversion mechanism

A technology of shunt mechanism and materials, applied in the direction of conveyor objects, transportation and packaging, packaging, etc., can solve the problems of increased cylinder cost, low work efficiency, material wear, etc., to achieve high efficiency and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

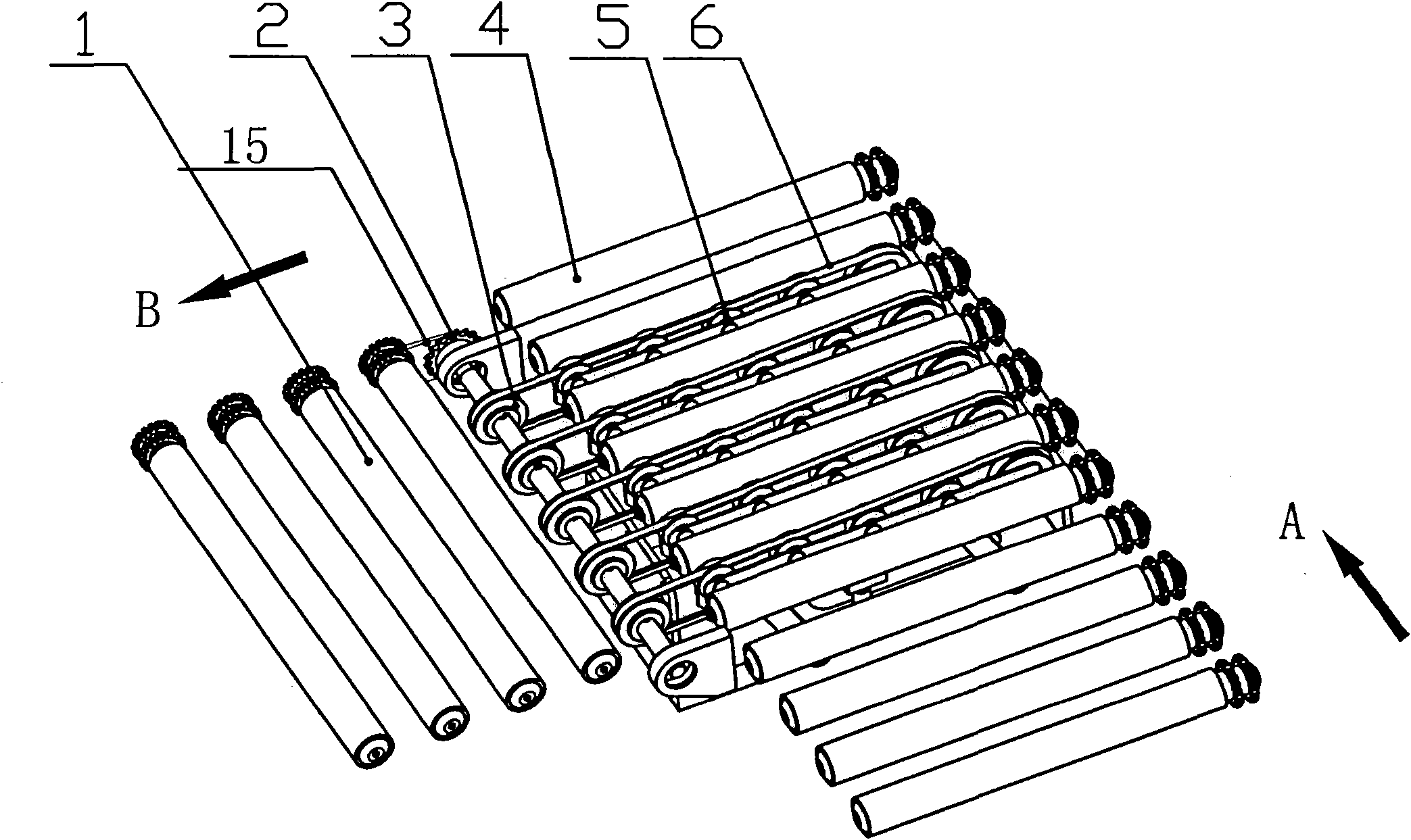

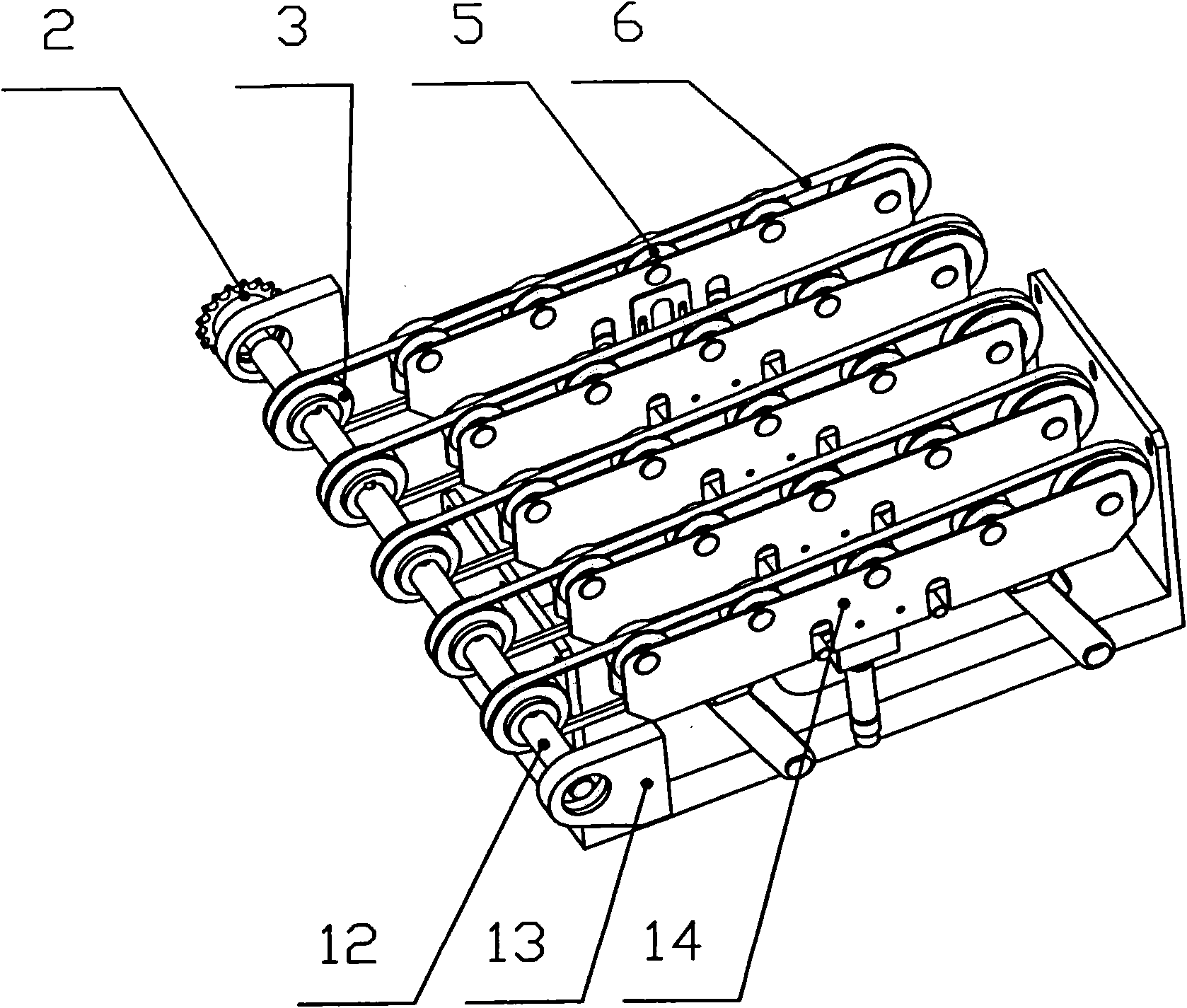

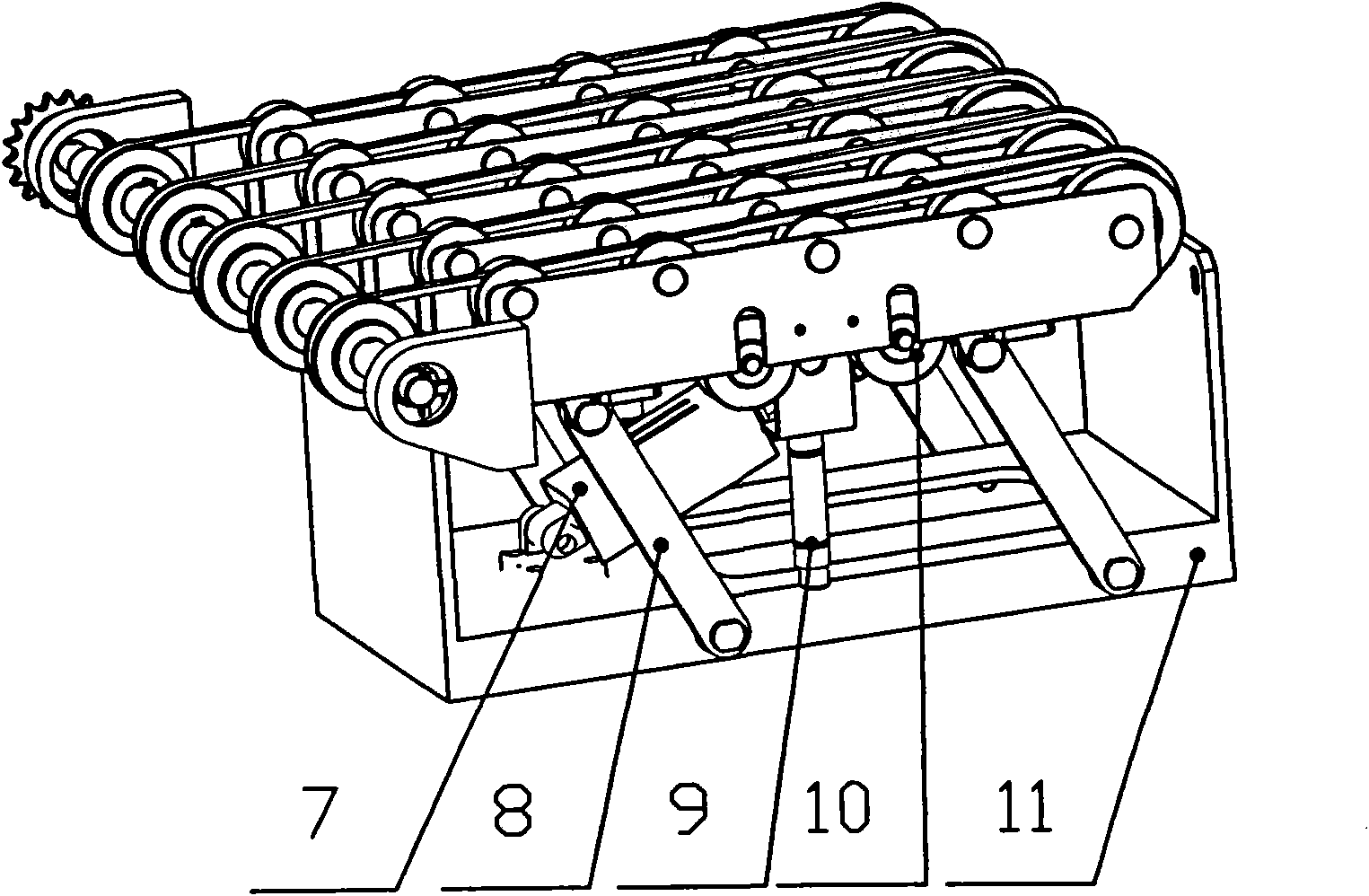

[0023] see Figure 1~3 , figure 1 It is a schematic diagram of the overall structure of the material distribution mechanism of the present invention. figure 2 It is a structural diagram of the state of the lane-dividing mechanism of the present invention. image 3 It is a structural diagram of the second state of the lane-dividing mechanism of the present invention. Depend on figure 1 , figure 2 and image 3 It can be seen that the material diverting mechanism of the present invention includes a first conveying raceway 4, a second conveying raceway 1 and a lane dividing mechanism, the first conveying raceway 4 and the second conveying raceway 1 are arranged at an angle of 90°, The lane-dividing mechanism is arranged at the turning point of the first conveying raceway 4 and the second conveying raceway 1, and placed under the first conveying raceway 4. The lane-dividing mechanism includes a fixed seat body 11, a bearing seat body 13, a Shaft 12, drive sprocket 2, drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com