Fan wheel structure and manufacturing method thereof

A technology of fan wheel and hub, applied in the field of fan wheel structure and its manufacturing, can solve the problems of poor uniformity, increased working hours, and different quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

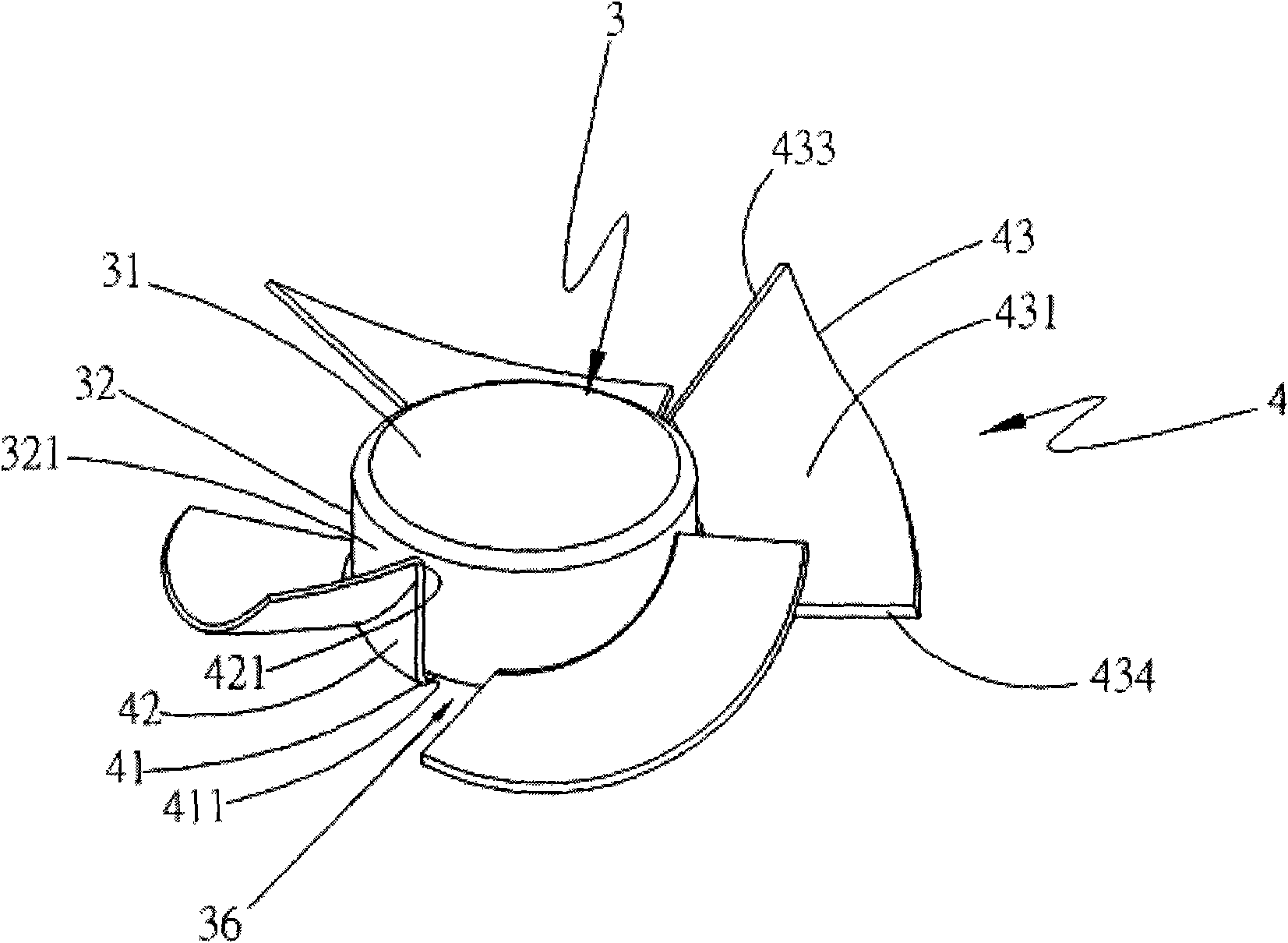

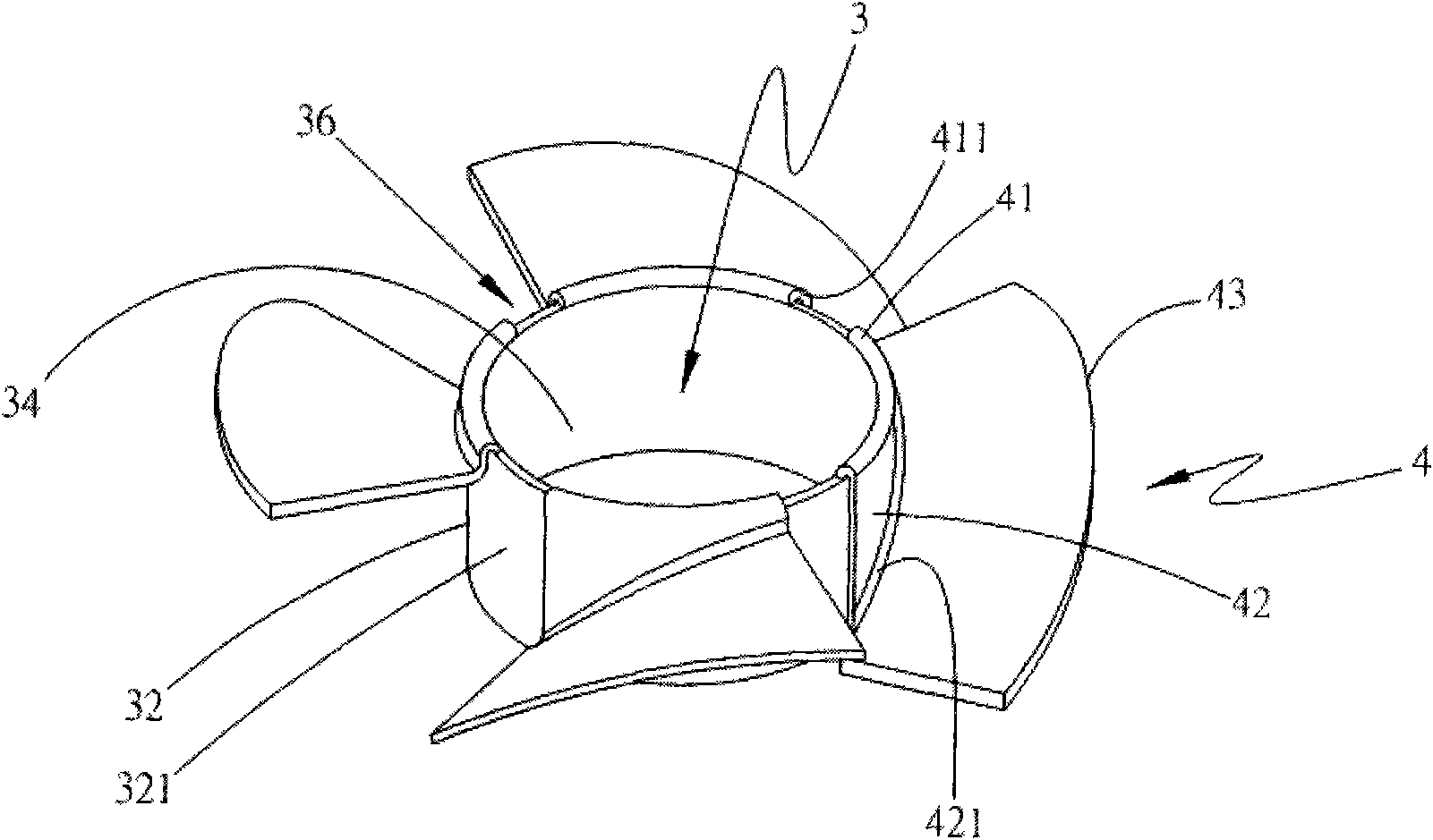

[0042] Please also refer to figure 2 , 2A As shown, the present invention is a fan wheel structure and its manufacturing method. In a preferred embodiment of the present invention, the fan wheel structure is made of metal materials, such as iron, aluminum, copper and metal alloys, and The fan wheel structure includes a hub 3 and at least one blade 4. The aforementioned hub 3 has a first portion 31 and a second portion 32 extending along the periphery of the first portion 31. One end of the first portion 31 is connected to one end of the second portion 32. , and define a hollow space 34, the aforesaid hollow space 34 is to accommodate the sleeve base and its motor in a fan frame (not shown in the figure), and it relatively covers the sleeve base and its motor (not shown in the fig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap