Oil return system of low-pressure cavity compressor air conditioner

An oil return system and compressor technology, which is applied to the oil return system field of low-pressure chamber compressor air conditioners, can solve the problems of wet operation, compressor oil foaming, and easy to burn out the compressor, so as to prevent wet operation and improve storage capacity. The effect of oil quantity and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

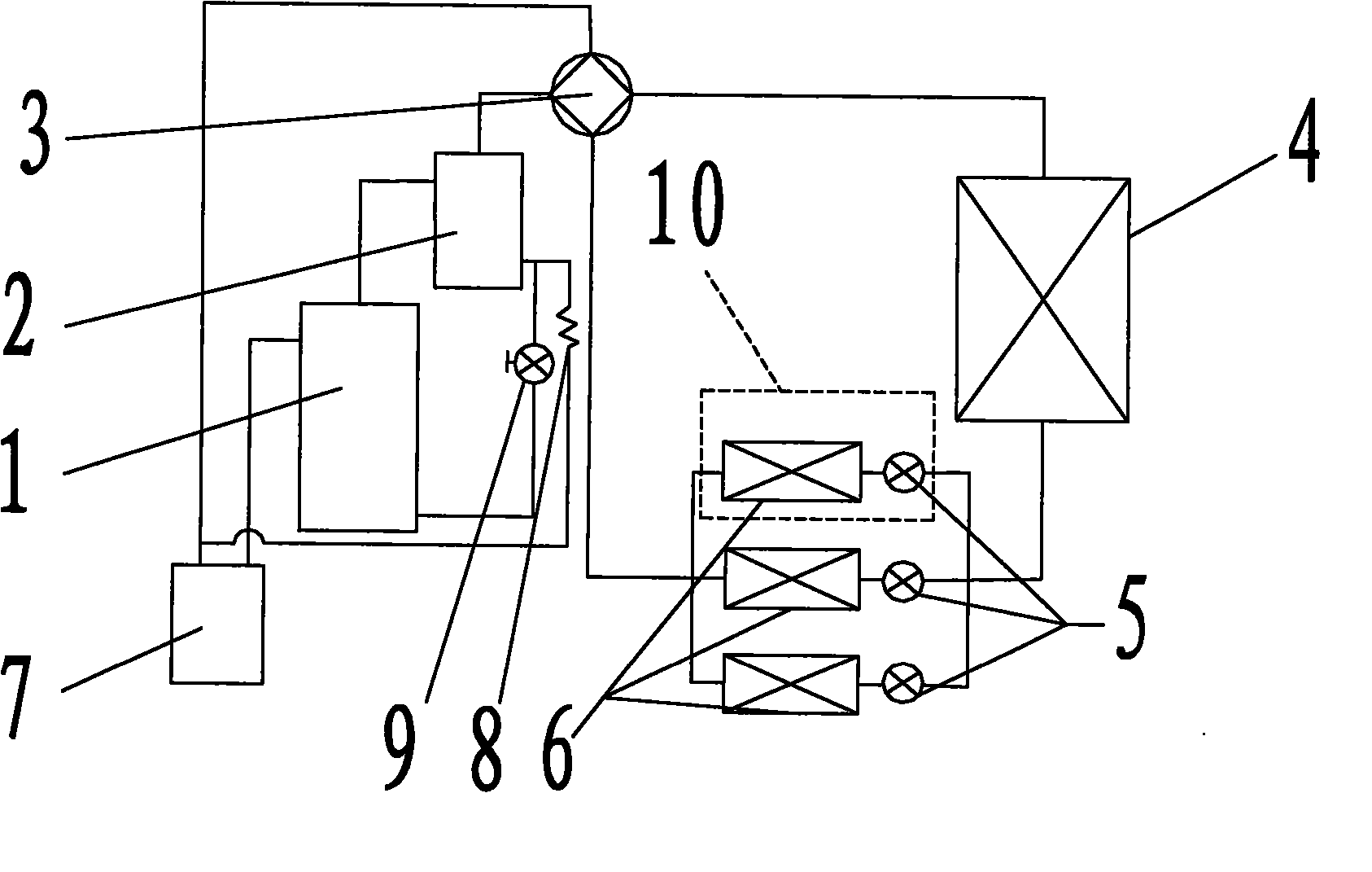

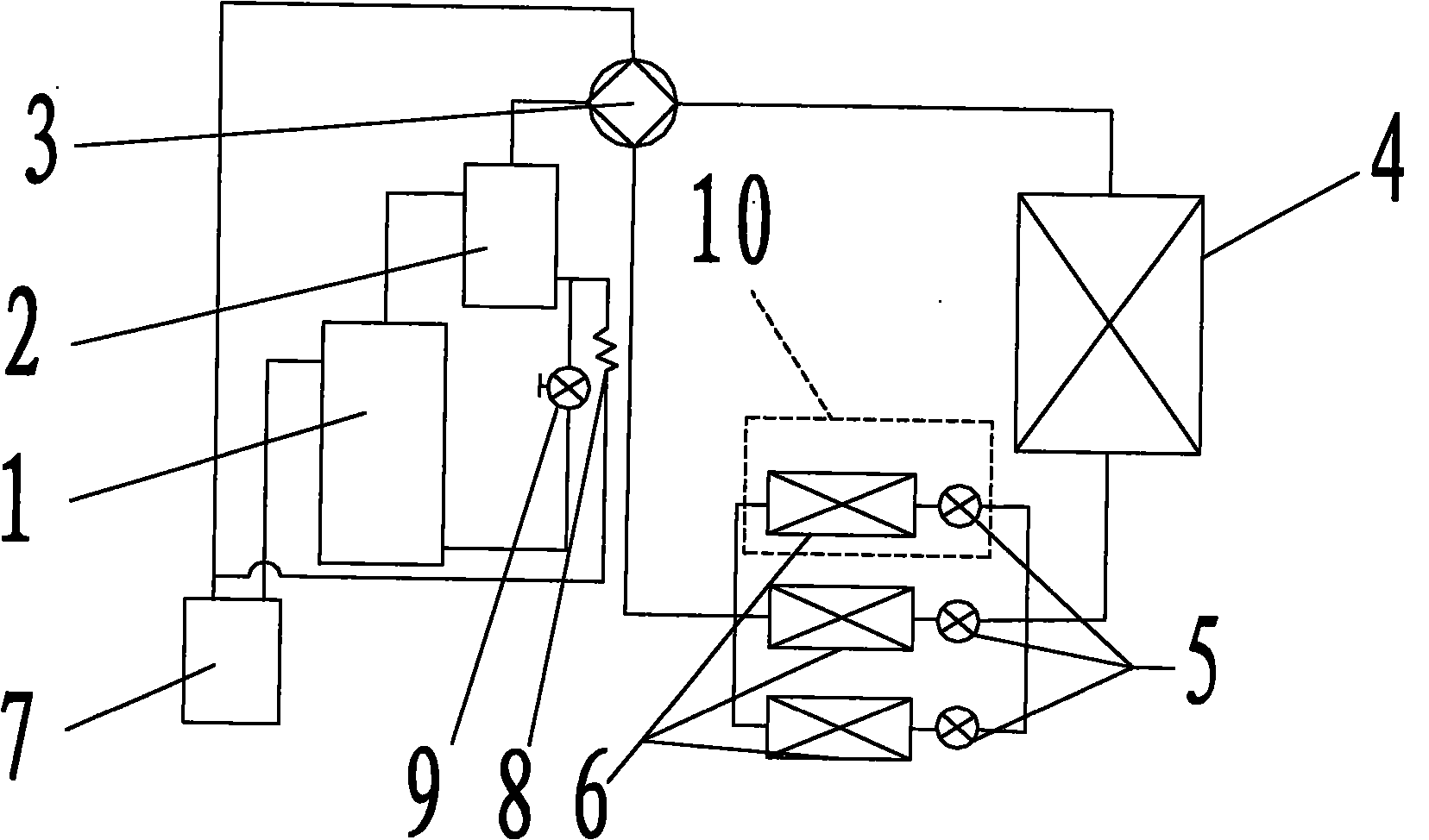

[0014] See figure 1 , which is a structural schematic diagram of the oil return system of the low-pressure chamber compressor air conditioner in a preferred embodiment of the present invention.

[0015] The oil return system of the low-pressure cavity compressor air conditioner provided by the present invention includes a compressor 1, an oil-gas separator 2, a four-way valve 3, an outdoor heat exchanger 4, and an indoor air conditioner composed of an electronic expansion valve 5 and an indoor heat exchanger 6 connected in series. Heat exchange mechanism 10, gas-liquid separator 7, compressor 1, oil-gas separator 2, four-way valve 3, outdoor heat exchanger 4, indoor heat exchange mechanism 10, four-way valve 3, gas-liquid separator 7 The circulation direction is sequentially con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com