Novel method for preparing high-power white LED with low color temperature and high color rendering property

A high-color rendering and high-power technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of low conversion efficiency of phosphor powder, low luminous efficiency, and low conversion efficiency of red phosphor powder, so as to improve photoluminescence Effect of conversion efficiency, improvement of luminous efficiency, and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

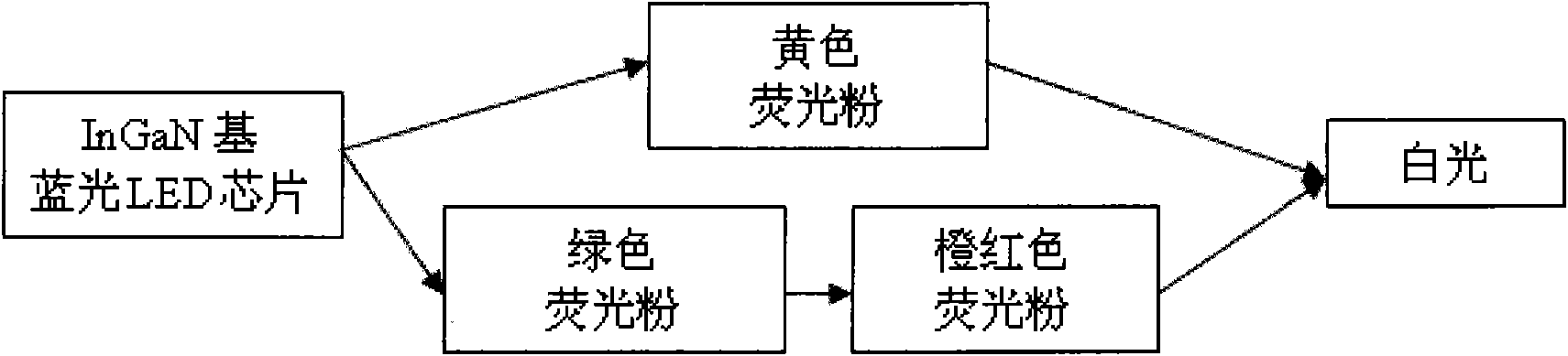

[0021] The new method of the present invention for preparing high-power white light LED with low color temperature and high color rendering adopts the conventional packaging process of white light LED. Taking the package of high-power 1W white light LED as an example, the packaging process is as follows: The chip is coated with a mixture of fluorescent powder and silica gel prepared according to a certain ratio, and baked to cure it, and then the optical lens is filled with high refractive index silica gel to make a φ5 round head white light LED. The difference between the present invention and the prior art lies in the difference in the phosphor powder used and the excitation mode of the phosphor powder. Therefore, only the composition of the phosphor powder and the excitation mode of the phosphor powder are described here.

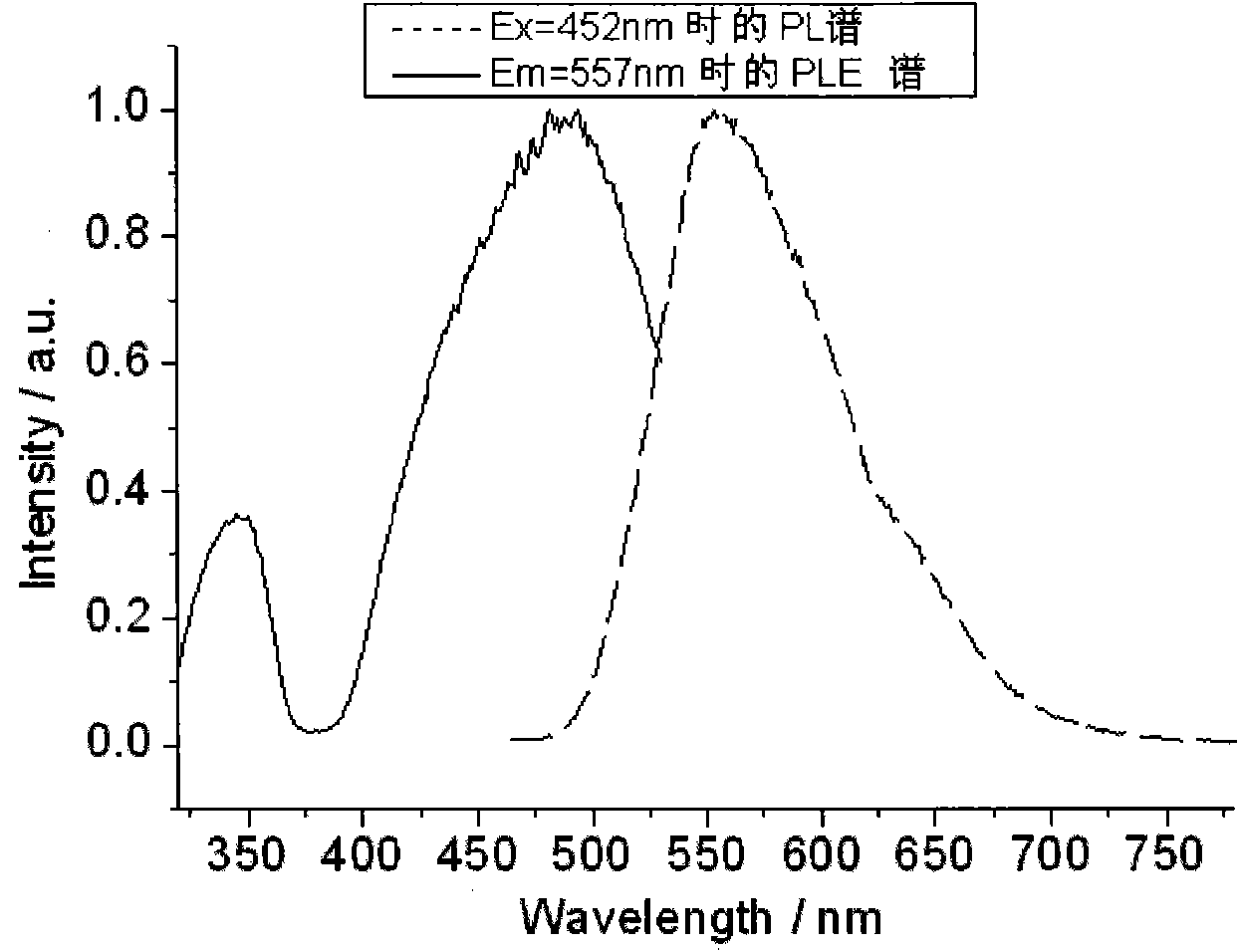

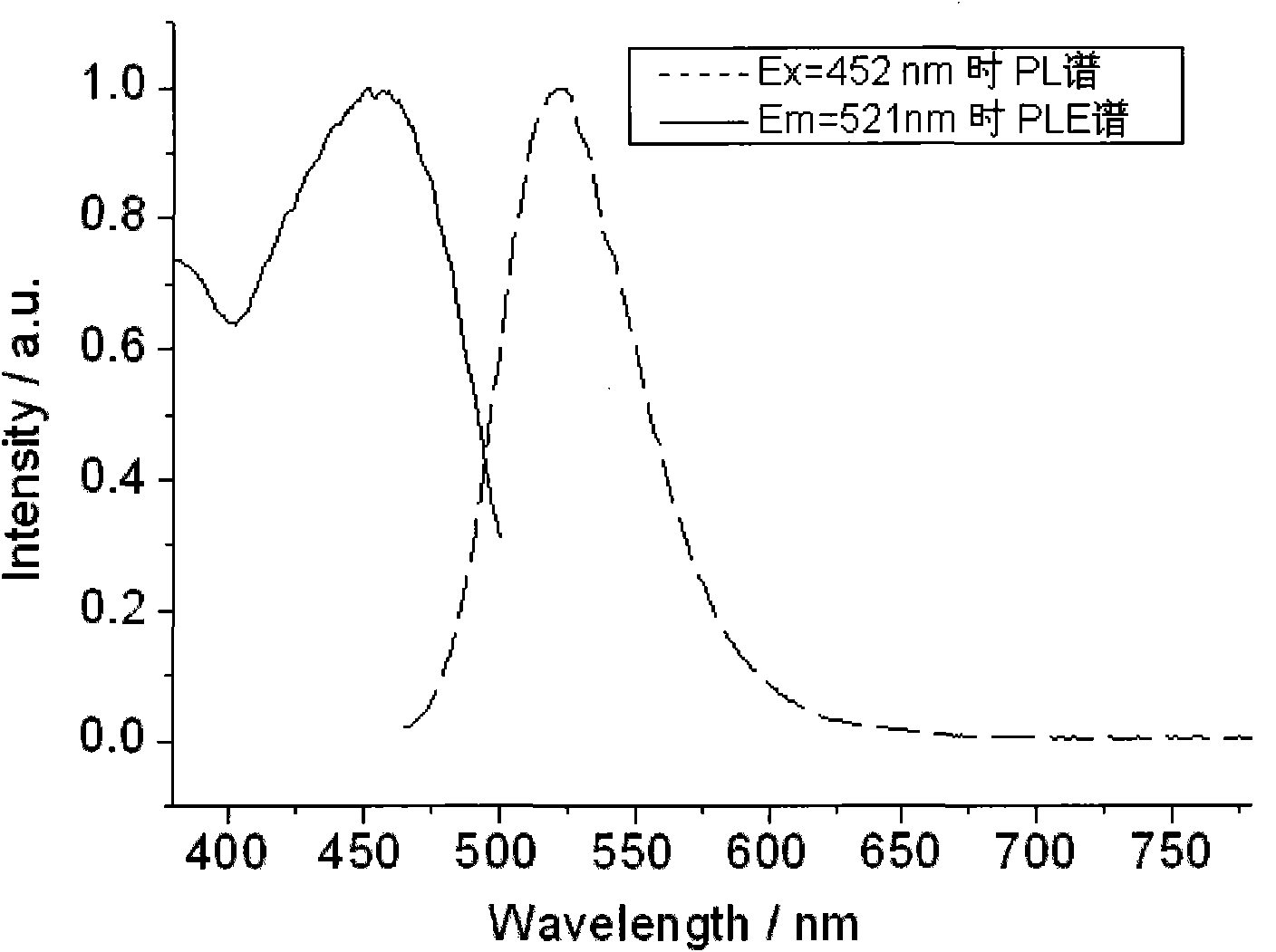

[0022] The present invention adopts InGaN-based blue LED chip to excite fluorescent powder, and fluorescent powder is yellow fluorescent powder (YAG:Ce ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminous efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com