Laser bonding device

A technology of laser welding and laser devices, which is applied in laser welding equipment, lasers, welding equipment, etc., and can solve the problems of complex connection between coated wires and terminals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

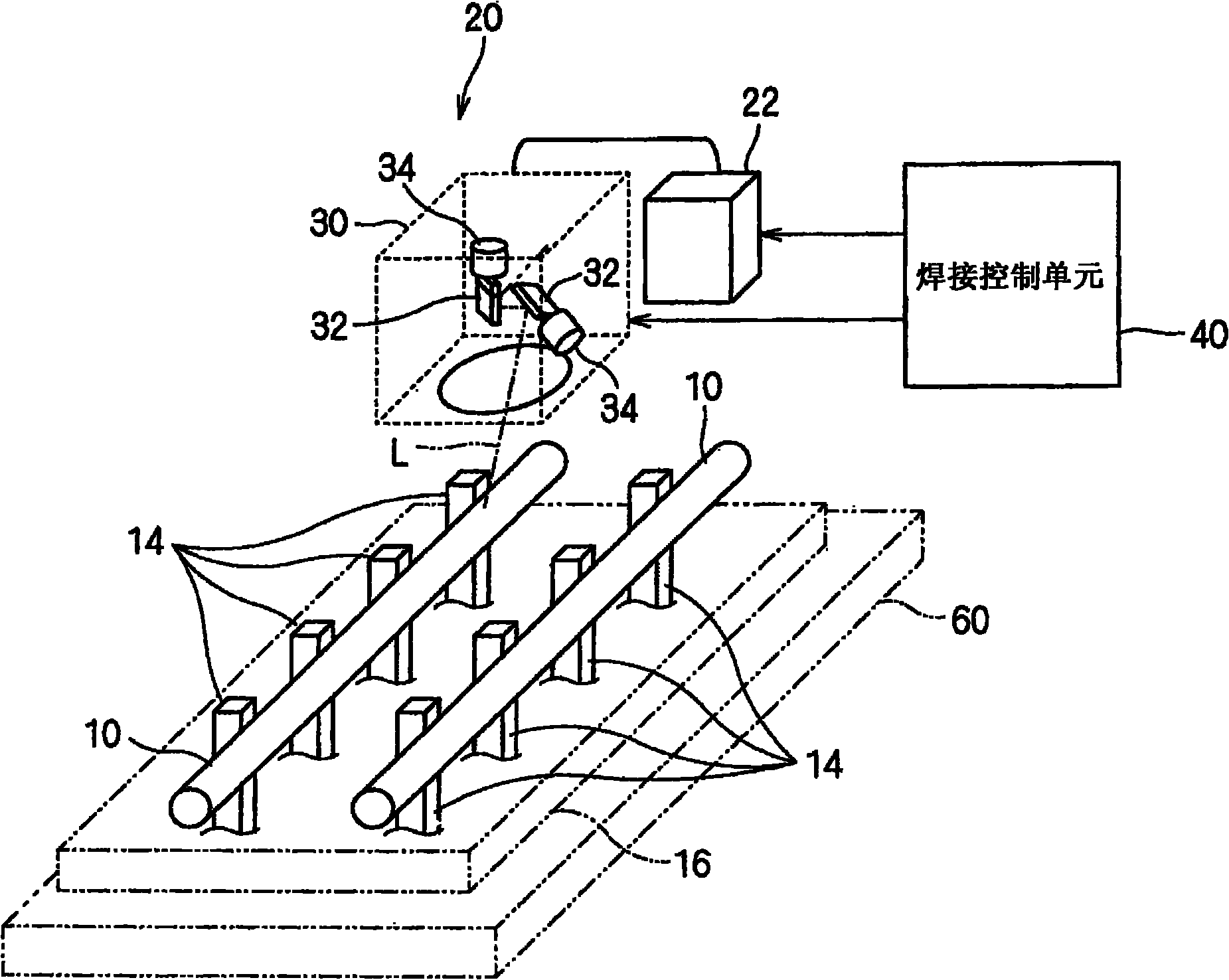

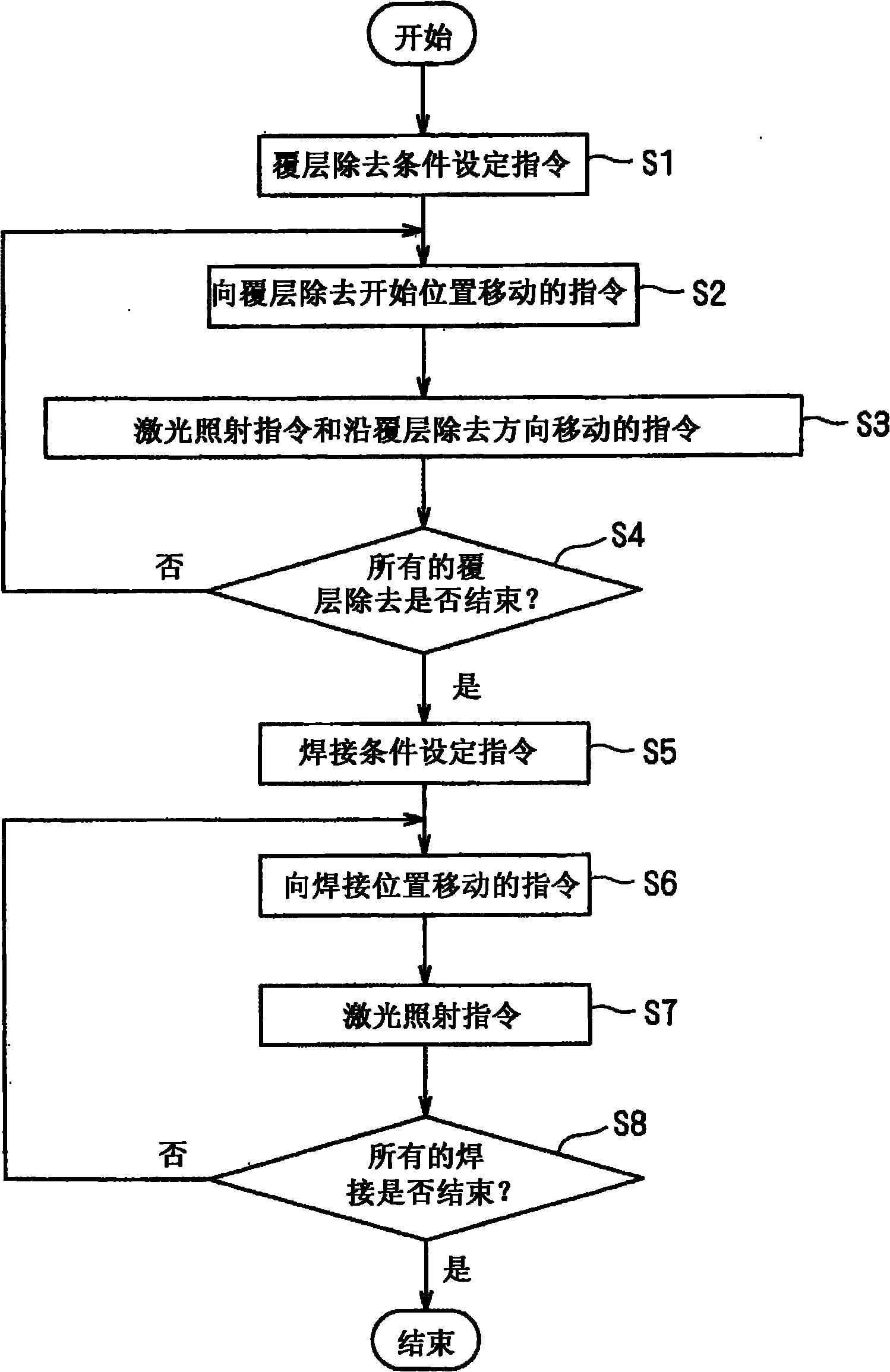

[0027] Hereinafter, the laser welding device according to the embodiment will be described. figure 1 It is a schematic diagram showing the laser welding device 20 .

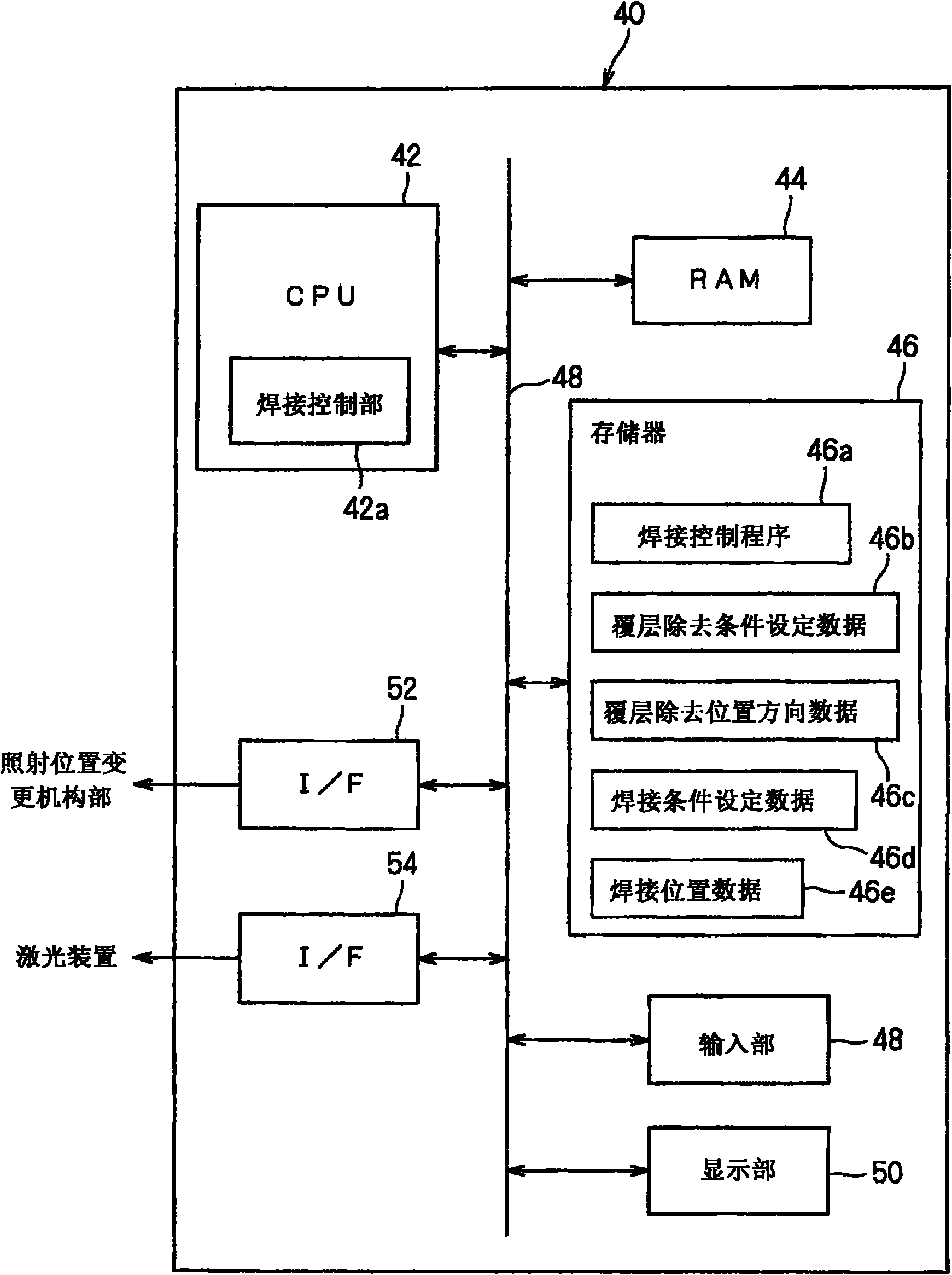

[0028] This laser welding device 20 is a device that connects the coated wire 10 and the terminal 14 by laser welding after removing the coating of the coated wire 10, and includes a laser device 22, an irradiation position changing mechanism part 30, and Welding control unit 40 .

[0029] Here, a specific example of welding objects will be described. The plurality of terminals 14 are elongated members formed of copper, annealed copper, or the like. One end of each terminal 14 is connected to the coated wire 10 as described later, and the other end of each terminal 14 can be electrically connected to other electronic components (power semiconductor elements, relays, fuses, connectors, etc.). The coated wire 10 is formed by coating the surface of a wire such as a copper wire or an annealed copper wire with an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com