Production method of 3-methyl sulfolane

A technology of methyl sulfolane and a production method, applied in the field of organic solvents, can solve the problems such as the failure of commercialization of 3-methyl sulfolane, and achieve the effects of reducing isoprene self-polymerization and reducing generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

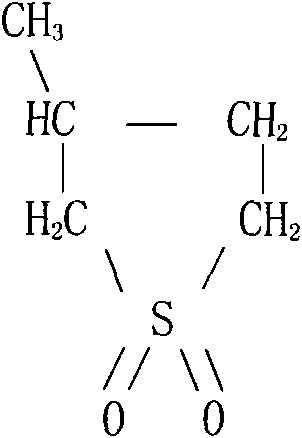

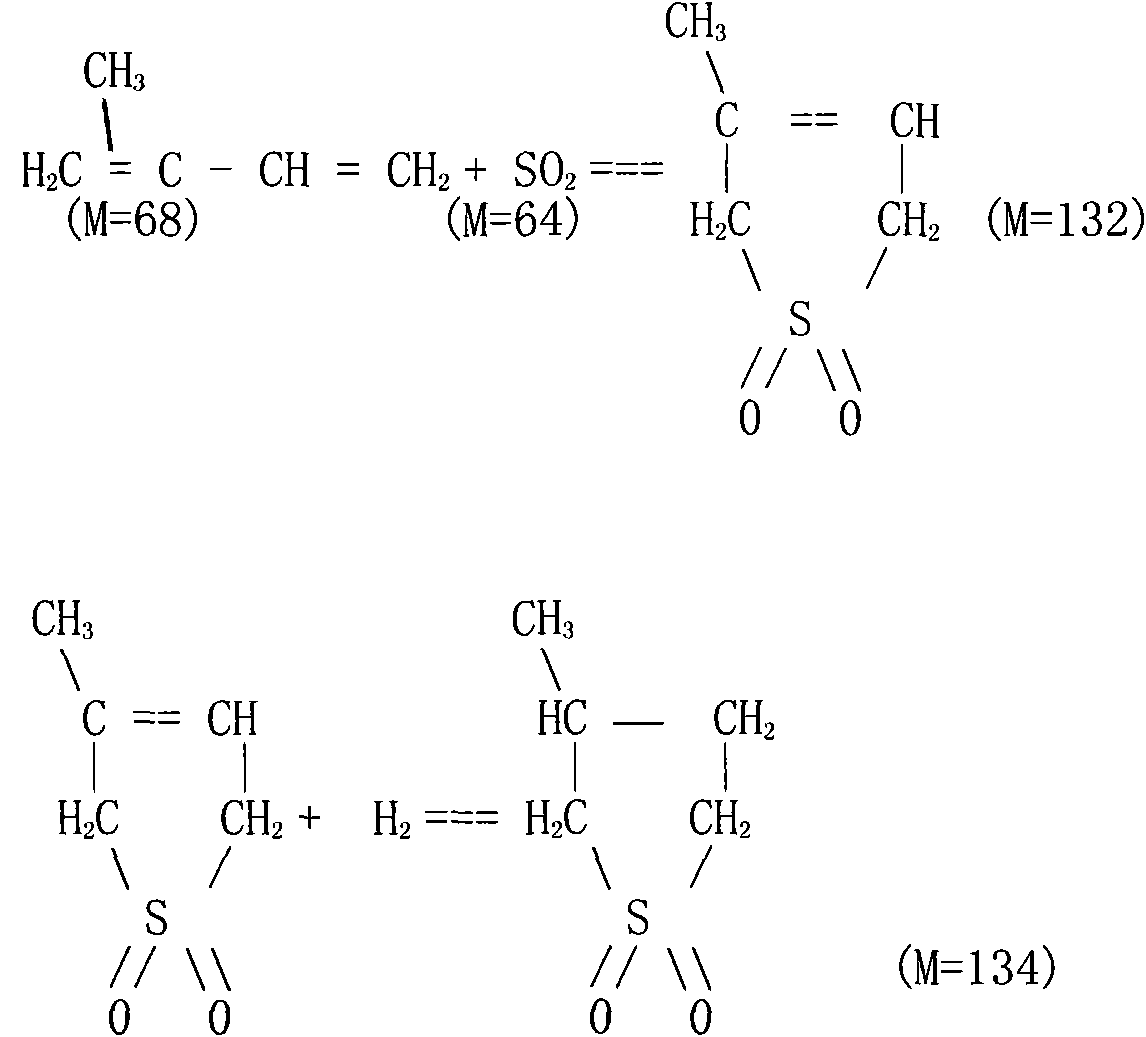

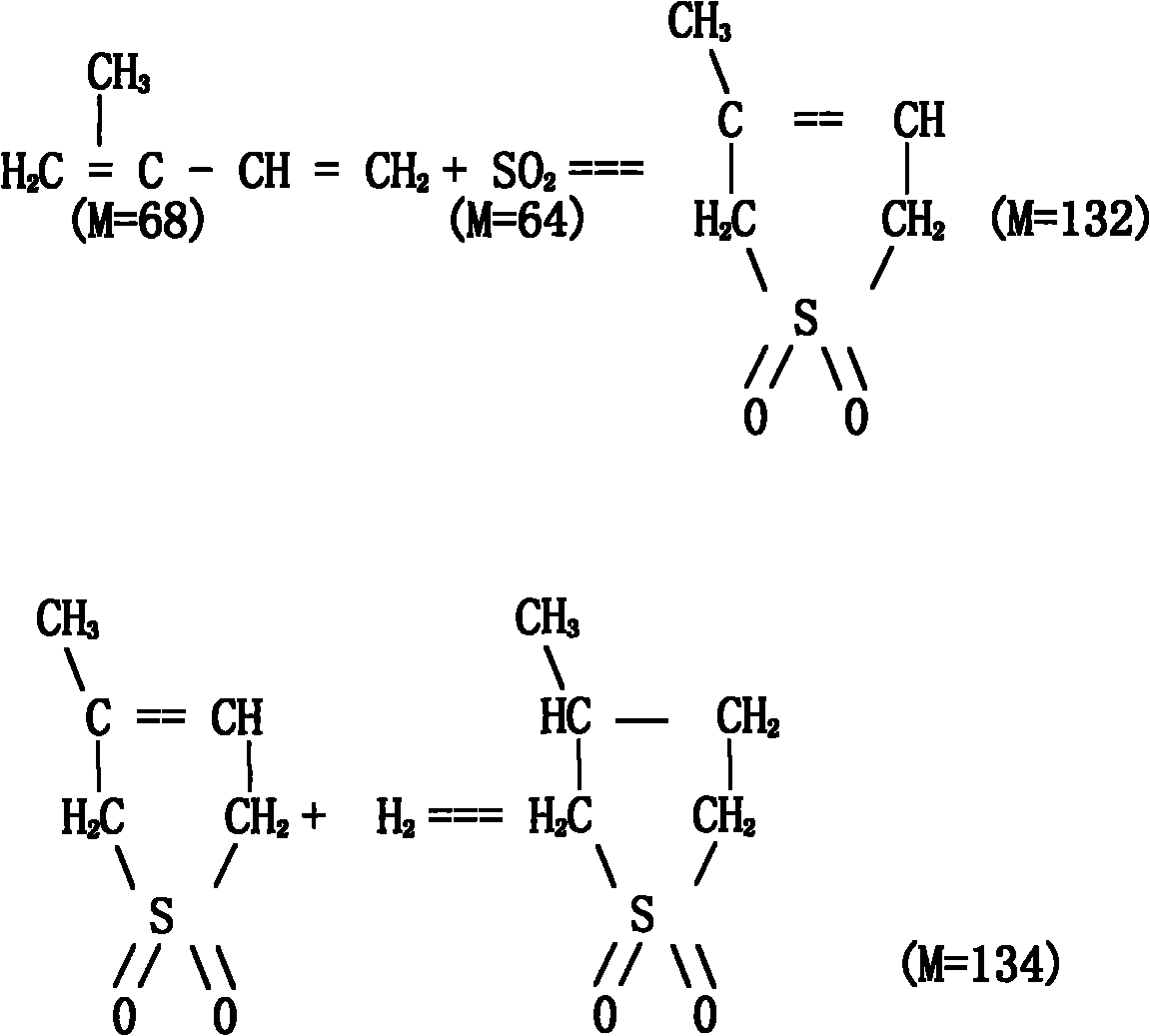

Method used

Image

Examples

Embodiment 1

[0013] First drop into 0.8 grams of polymerization inhibitor hydroquinone, then add 230 grams of liquid sulfur dioxide and 204 grams of isoprene successively, heat while stirring, stop heating when the temperature rises to 80 ° C, because the reaction temperature of the material will continue to rise, At this time, water was used to cool it down, and the temperature was controlled at 90°C-100°C (at this time, the pressure in the reactor was 2.5-3.0Mpa), and when the temperature rose slowly and did not cool down without water and did not heat up, it was stirred for another 20 minutes to obtain crude Sulphone, the content of sulphone is detected by chemical method (bromine value determination method), the yield of sulphone is 82.3%; add water equal to the weight of the crude sulphone for dilution, filter out the flocculent precipitate and then transfer it to the hydrogenation reactor At the same time, add 17.4 grams of Raney nickel catalyst, after stirring, pass high-purity hydro...

Embodiment 2

[0015] First drop into 0.8 grams of polymerization inhibitor hydroquinone, then add 230 grams of liquid sulfur dioxide and 204 grams of isoprene successively, heat while stirring, stop heating when the temperature rises to 80 ° C, because the reaction temperature of the material will continue to rise, At this time, water was used to cool it down, and the temperature was controlled at 90°C-100°C (at this time, the pressure in the reactor was 2.5-3.0Mpa), and when the temperature rose slowly and did not cool down without water and did not heat up, it was stirred for another 20 minutes to obtain crude sulfene, the yield of sulfone is 82.5%; add water equal to the weight of crude sulfone to dilute, filter out the flocculent precipitate and then move it into the hydrogenation reactor, add 30.5 grams of Raney nickel catalyst at the same time, stir and then Put high-purity hydrogen into the reaction kettle for hydrogenation reaction. The hydrogen pressure is generally 2.0Mpa, and the ...

Embodiment 3

[0017] First drop into 0.8 grams of polymerization inhibitor hydroquinone, then add 230 grams of liquid sulfur dioxide and 204 grams of isoprene successively, heat while stirring, stop heating when the temperature rises to 80 ° C, because the reaction temperature of the material will continue to rise, At this time, water was used to cool it down, and the temperature was controlled at 90°C-100°C (at this time, the pressure in the reactor was 2.5-3.0Mpa), and when the temperature rose slowly and did not cool down without water and did not heat up, it was stirred for another 20 minutes to obtain crude sulfone, the yield of sulfone is 82.6%; add water equal to the weight of crude sulfone to dilute, filter out the flocculent precipitate and then move it into the hydrogenation reactor, add 43.4 grams of Raney nickel catalyst at the same time, stir and then Put high-purity hydrogen into the reaction kettle for hydrogenation reaction. The hydrogen pressure is generally 2.0Mpa, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com