Squeezed hole construction process

A construction technology and hole-forming technology, which is applied in the direction of infrastructure engineering, construction, sheet pile walls, etc., can solve the problems of high noise, high energy demand, and easy buckling of steel pipe piles, etc., and achieve low energy consumption, controllable process, The effect of increased bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

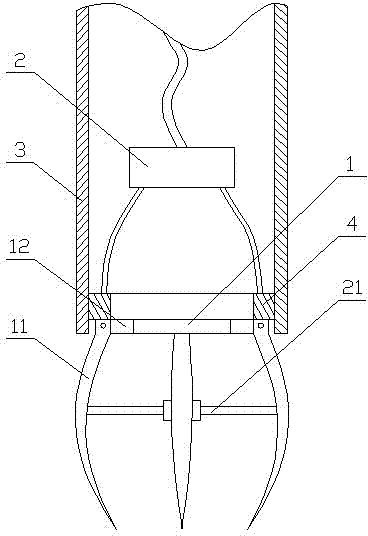

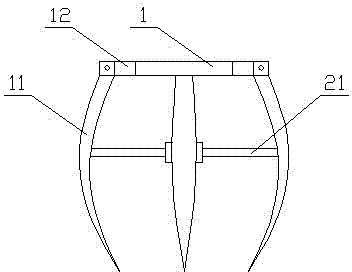

[0028] Extrusion and expansion hole construction equipment, such as figure 1 , 2 , 3, including a steel pipe pile 3, a drill bit 1 and a pressure device 2, the drill bit 1 includes a sheath 12 and an arc-shaped digging claw 11. The arc-shaped digging claws 11 are sleeved on the sheath 12, and are easy to assemble and disassemble, and can be interchanged.

[0029] It also includes a water injection pipeline and a mud pump, the diameter of the drill bit 1 is smaller than the inner diameter of the steel pipe pile 3, the drill bit 1 is connected to the retaining ring 4, and the pressure device 2 is connected to the retaining ring 4. A retaining ring 4 is set between the drill bit 1 and the pressure device 2. The retaining ring 4 carries all the force transmitted by the pressure device 2 and transmits the pressure to the drill bit 1. This design greatly protects the drill bit 1 and improves the performance of the drill bit 1. service life.

[0030] There are four arc-shaped digg...

Embodiment 2

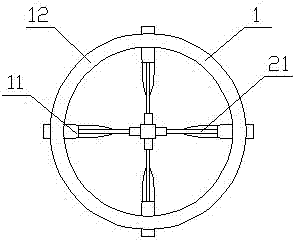

[0041] Extrusion and expansion hole construction equipment, such as figure 1 , 4 , 5, it includes a steel pipe pile 3, a drill bit 1 and a pressure device 2, and the drill bit 1 includes a sheath 12 and an arc-shaped digging claw 11. The arc-shaped digging claws 11 are sleeved on the sheath 12, and are easy to assemble and disassemble, and can be interchanged.

[0042] Preferably, it also includes a water injection pipeline and a mud pump, the diameter of the drill bit 1 is smaller than the inner diameter of the steel pipe pile 3, the drill bit 1 is connected to the retaining ring 4, and the pressure device 2 is connected to the retaining ring 4. A retaining ring 4 is set between the drill bit 1 and the pressure device 2. The retaining ring 4 carries all the force transmitted by the pressure device 2 and transmits the pressure to the drill bit 1. This design greatly protects the drill bit 1 and improves the performance of the drill bit 1. service life.

[0043] There are si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com