Electrically-operated servo valve and method for controlling same

A technology of servo controller and electric valve, applied in the direction of valve details, valve devices, engine components, etc., can solve problems such as high cost, high requirements for the use environment of photoelectric encoders, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

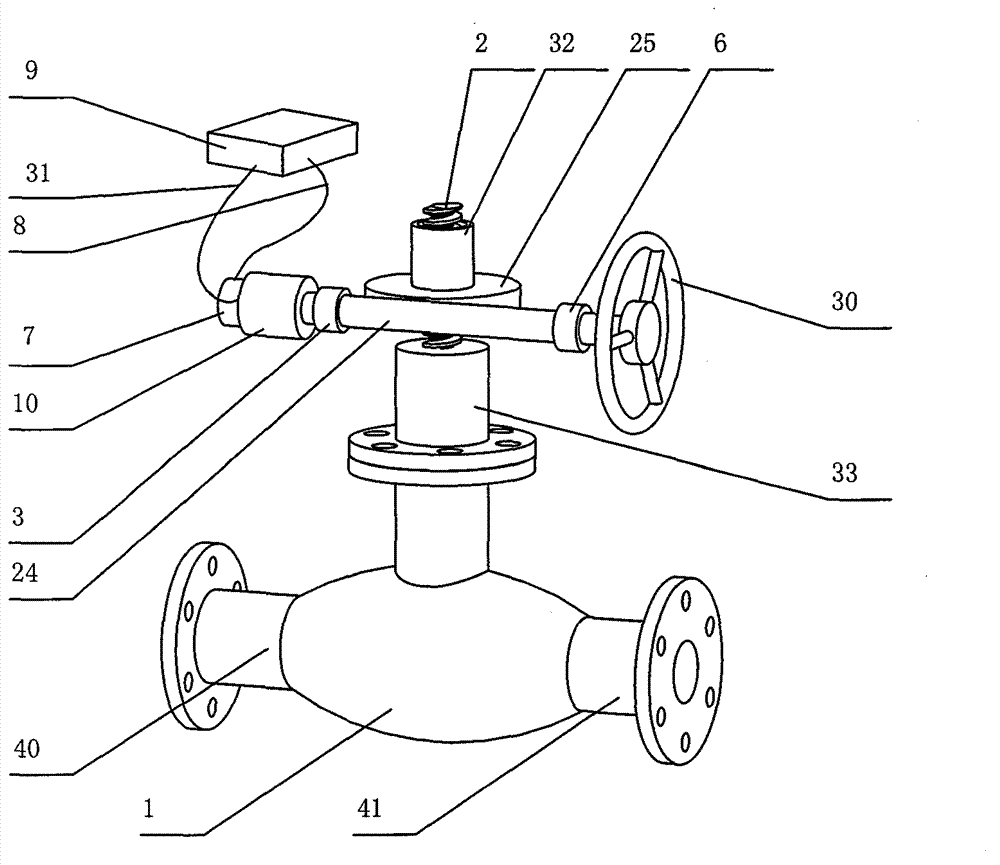

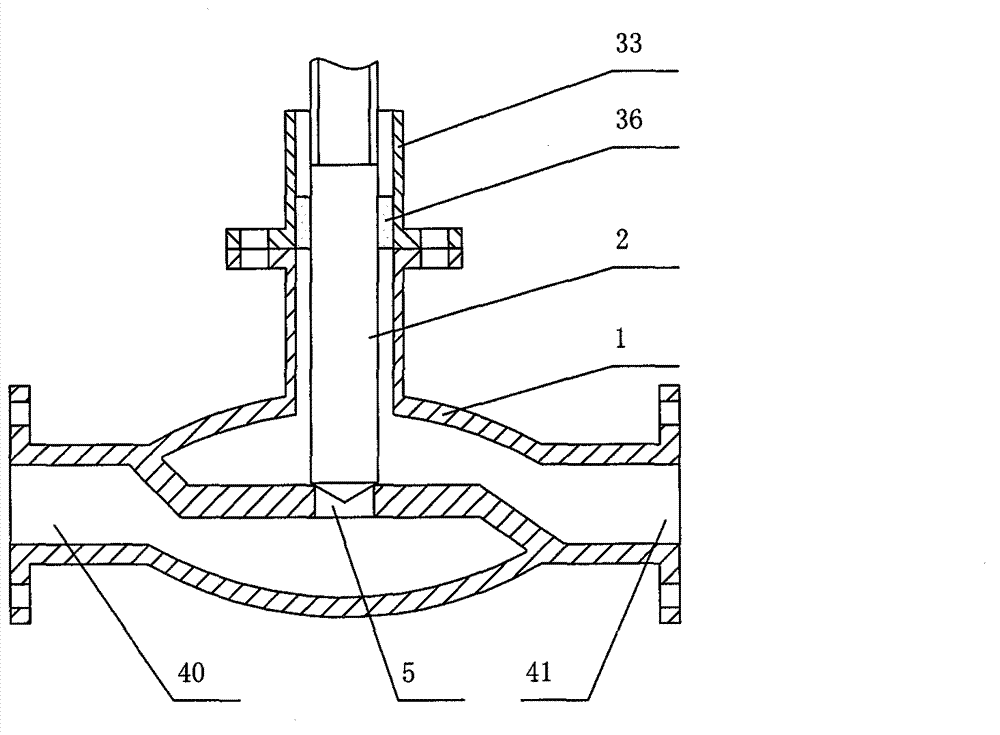

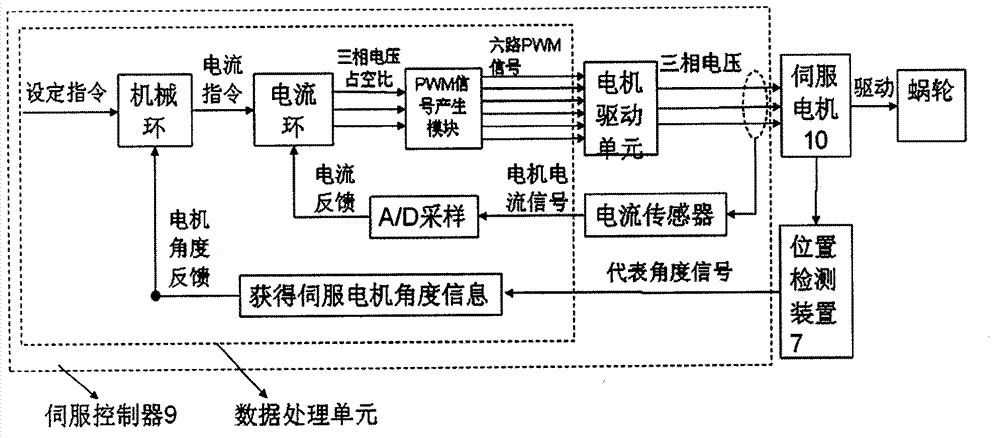

[0135] figure 1 It is a schematic diagram of the overall structure of Embodiment 1 of the servo electric valve of the present invention. Such as figure 1 As shown, the present invention provides a servo electric valve, which includes a valve body 1, and the two ends of the valve body 1 are a liquid outlet chamber 41 and a liquid inlet chamber 40 respectively. The valve body 1 is provided with a valve stem 2, the output of the servo motor 10 is connected to the worm 24 at the input end of the reducer through the coupling 3, the turbine 25 at the output end of the reducer is connected to the valve stem 2, and the valve stem 2 is connected to the valve hole 5 And control the opening of the valve hole 5. The motor shaft of the servo motor 10 is provided with a position detection device 7, and the position detection device 7 inputs signals to the servo controller 9 to control the servo motor 10 to drive the reducer and control the opening of the valve hole 5 through the valve rod...

Embodiment 2

[0153] Figure 7 It is a schematic diagram of the overall structure of Embodiment 2 of the servo electric valve of the present invention. Such as Figure 7 As shown, the turbine shaft 32 is also provided with a position detection device 7, the position detection device 7 detects the angle information of the valve stem 2, and the input signal is sent to the servo controller 9, and the servo controller 9 controls the servo motor 10 to drive the reducer and pass the valve stem. 2 Control the opening of the valve hole 5.

[0154] Figure 8 It is a schematic diagram of the control structure of Embodiment 2 of the servo electric valve of the present invention. Such as Figure 8 As shown, the difference from Embodiment 1 is that a position detection device 7 is respectively installed on the worm 2 and the motor shaft, which are respectively used to detect the angular position of the worm 2 and the angular position of the motor shaft, and transmit them to the servo controller 9 ,...

Embodiment 3

[0157] Figure 9 It is a schematic diagram of the overall structure of Embodiment 3 of the servo electric valve of the present invention. Such as Figure 9 As shown, the difference from the second embodiment is that a transmission mechanism is additionally provided on the valve stem 2, the driving part of the transmission mechanism is arranged on the valve stem 2, and a position detection device 7 is provided on the rotating shaft of the driven part. In this embodiment, the driving part of the transmission mechanism is the gear 43, and the driven part is the gear 44, that is, the gear transmission mechanism. A gear 44 is provided on the gear shaft 42 . The position detection device 7 inputs signals to the servo controller 9, and the servo controller 9 controls the servo motor 10 to drive the reducer and controls the opening of the valve hole 5 through the valve stem 2.

[0158] figure 2 to combine Figure 9 As shown, when the valve stem 2 is at the bottom, the valve hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com