Hydrogen supplying device

A technology for supplying hydrogen and hydrides, which is applied in the production of hydrogen, fuel cell additives, fuel cells, etc., and can solve the problems of reduced efficiency, high price, and inability to shake up and down, left and right, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

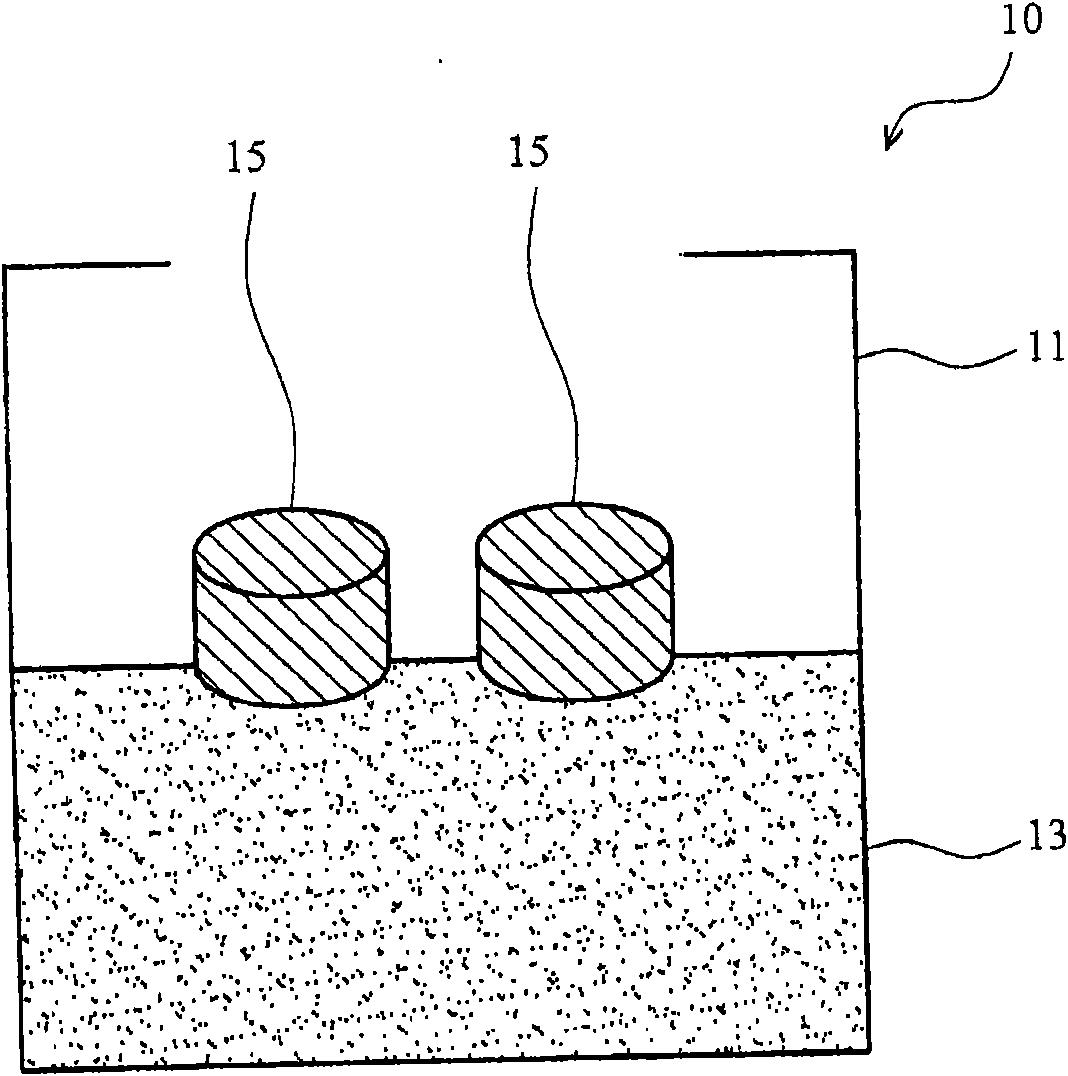

[0028] Take 1g of water-absorbing polymer sodium polyacrylate and place it in a container, and add 25g of water. After standing for 10 minutes, a non-flowing hydrogel was formed.

[0029] With reference to the method of No. 98108205 of Chinese Taiwan patent application number, get solid hydride (NaBH 4 ), catalyst (Co 2+ / IR-120) after high-speed ball milling, then add silicone rubber to form flexible solid hydrogen fuel. Then, the above-mentioned solid hydrogen fuel was formed into an ingot by a granulator, and each ingot of the solid hydrogen fuel contained 1 g of solid hydride, 0.1 g of catalyst, and 0.1 g of silicone rubber.

[0030] After placing two ingots of solid hydrogen fuel on the above water gel, the solid hydrogen fuel will absorb water and react to form hydrogen gas. After measurement, the relationship between hydrogen desorption rate and time is shown in Figure 4 shown.

Embodiment 2

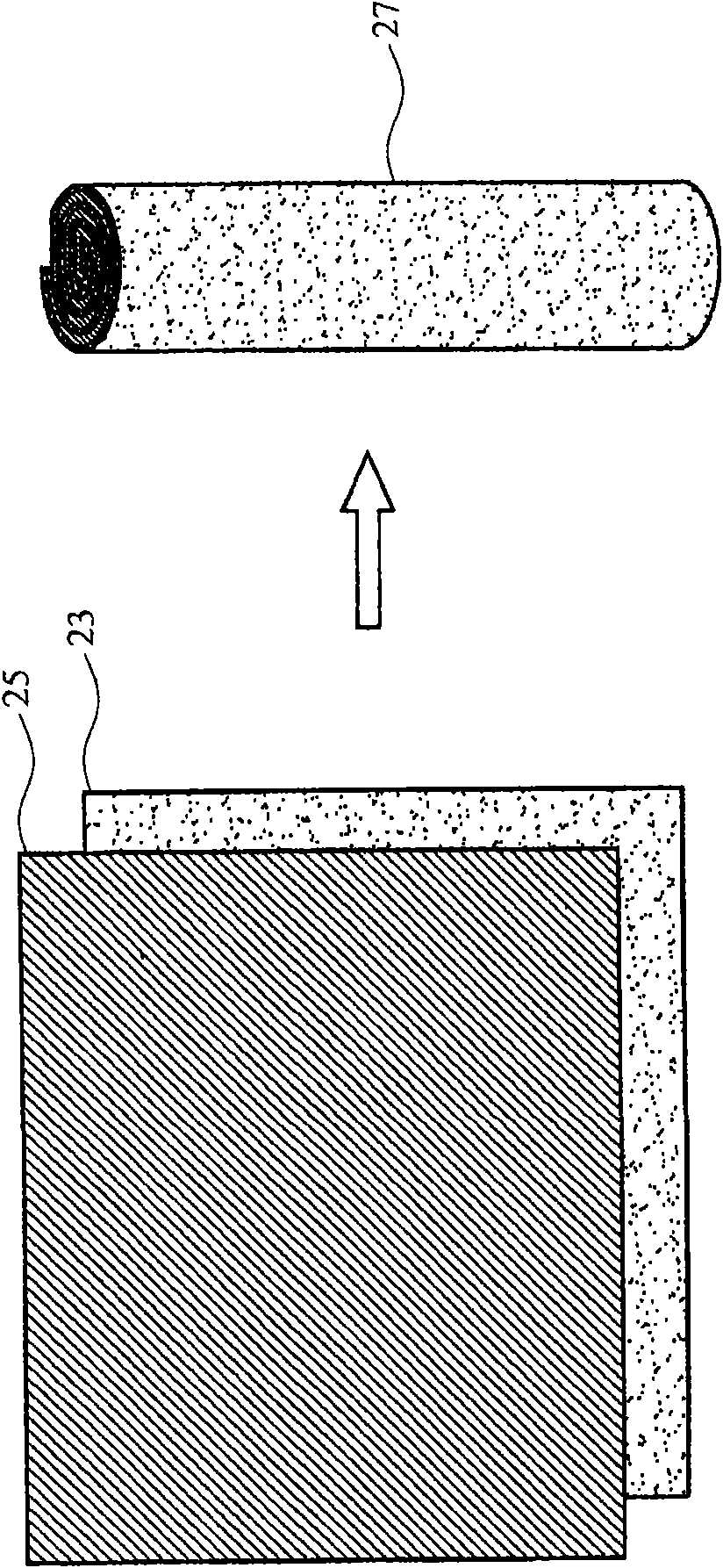

[0032] Take 0.5g of sodium polyacrylate and evenly spread it on the water-absorbent cotton material (5cm*13cm*0.05cm, ultra-thin cosmetic cotton KK-II purchased from Yani International Co., Ltd.) to form a sheet-shaped water-absorbent material.

[0033] With reference to the method of No. 98108205 of Chinese Taiwan patent application number, get solid hydride (NaBH 4 ), catalyst (Co 2+ / IR-120) after high-speed ball milling, then add silicone rubber to form flexible solid hydrogen fuel. Next, the above-mentioned solid hydrogen fuel is pressed into sheets and then cut to form a sheet-shaped solid hydrogen fuel (4cm*11cm*0.1cm).

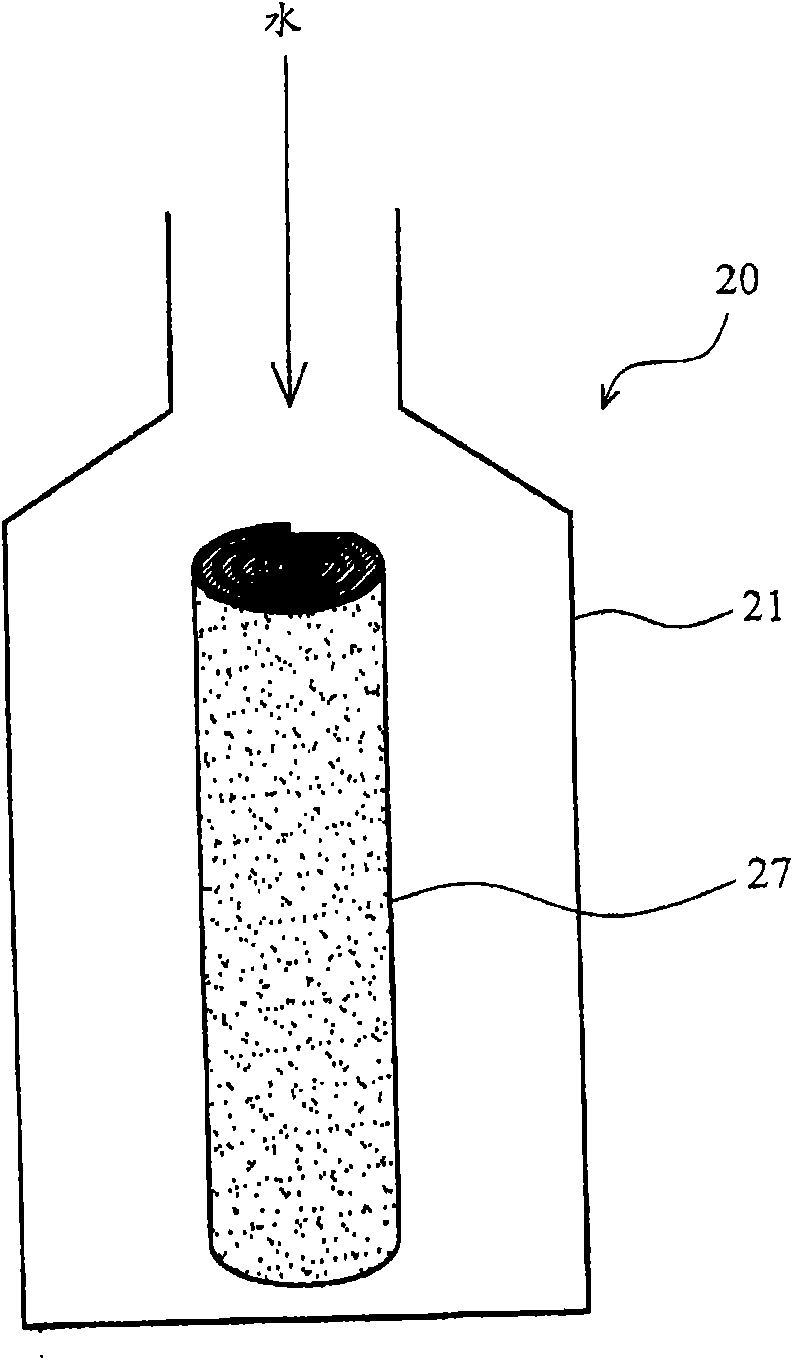

[0034] The sheet-shaped water-absorbing material and the sheet-shaped solid hydrogen fuel are laminated and rolled into a rod, and the rod is placed in a container. After adding 20g of water to the container, the water-absorbent material quickly absorbs water. After standing for five minutes, pour out the excess water and measure the hydrogen releas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com