Catalyst for polymerization of olefin, and process for production of olefin polymer

A technology of olefin polymerization and catalyst, which is applied in the field of olefin polymerization catalyst and a kind of production of olefin polymer, which can solve the problems such as unsatisfactory molding processability

Inactive Publication Date: 2010-11-03

SUMITOMO CHEM CO LTD

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the above-mentioned novel ethylene-α-olefin copolymers are still not satisfactory in their molding processability.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

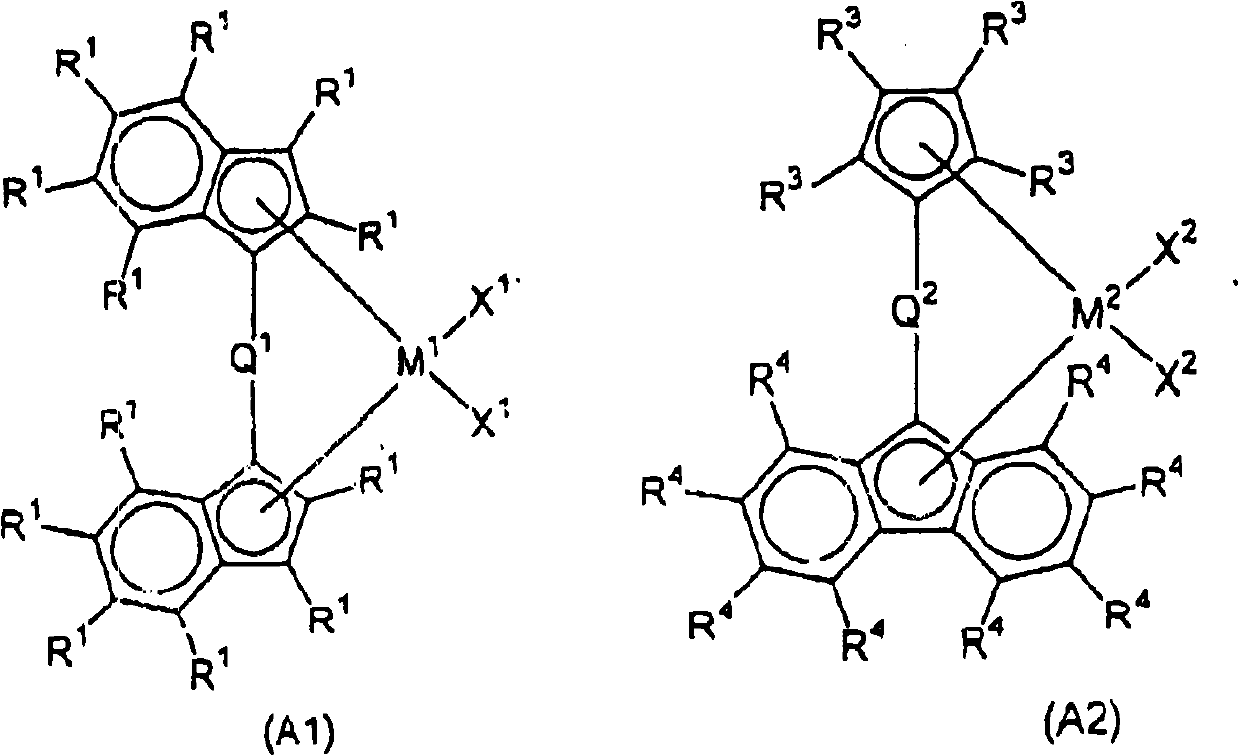

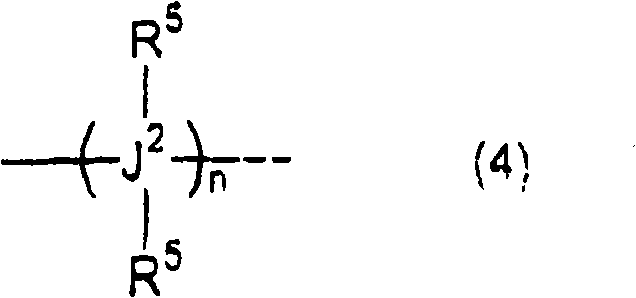

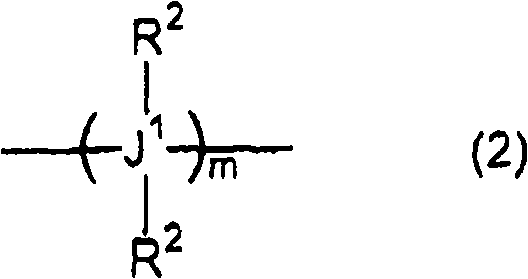

Disclosed is a catalyst for use in the polymerization of an olefin, which is produced by contacting a specific transition metal compound (A1), a specific transition metal compound (A2) and a specific solid catalyst component (B) with one another, wherein the component (A1) and the component (A2) are contacted with each other at a molar ratio (i.e., (A1) / (A2) ratio) of 1 to 90. (A1) (A2) wherein M1 and M2 independently represent a transition metal atom belonging to Group IV on the periodic table; X1, X2, R1, R3 and R4 independently represent a hydrogen atom, a halogen atom, a hydrocarbyl group, a hydrocarbyloxy group or the like; and Q1 and Q2 independently represent a specific cross-linking group.

Description

technical field The present invention relates to an olefin polymerization catalyst and a method for producing olefin polymer. Background technique Olefin polymers such as ethylene-α-olefin copolymers are molded into articles such as films, sheets and bottles by various molding methods, and these molded articles are used in various applications such as food packaging materials. Ethylene-α-olefin copolymers produced with metallocene catalysts are well known in the art, and said copolymers are so excellent in their mechanical strength such as impact strength and tensile strength that thin-walled molded articles can be expected to be obtained from these copolymers (thus obtain lightweight, low-cost molded articles) while maintaining their mechanical strength, and have been investigated for their use for various applications. However, the extrusion load of ethylene-α-olefin copolymers produced with conventional metallocene catalysts is so high under extrusion, the tensile stren...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F4/6592C08F10/00

CPCC08F4/65908C08F10/00C08F4/65912C08F4/65916C08F210/16C08F4/65927C08F4/65904C08F210/08C08F2500/04C08F2500/11C08F2500/17

Inventor 越智直子野末佳伸川岛康丰

Owner SUMITOMO CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com