Forged and synthesized main shaft for biomass particle granulating machine

A biomass granulation and granulator technology, applied in the direction of die extrusion granulation, etc., can solve the problems of difficult to meet the high strength and high bearing capacity of the main shaft, the quality of the main shaft material is not high, and the production cost remains high, and achieves economical manufacturing. High efficiency, internal compactness, and reduced stock removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with accompanying drawing:

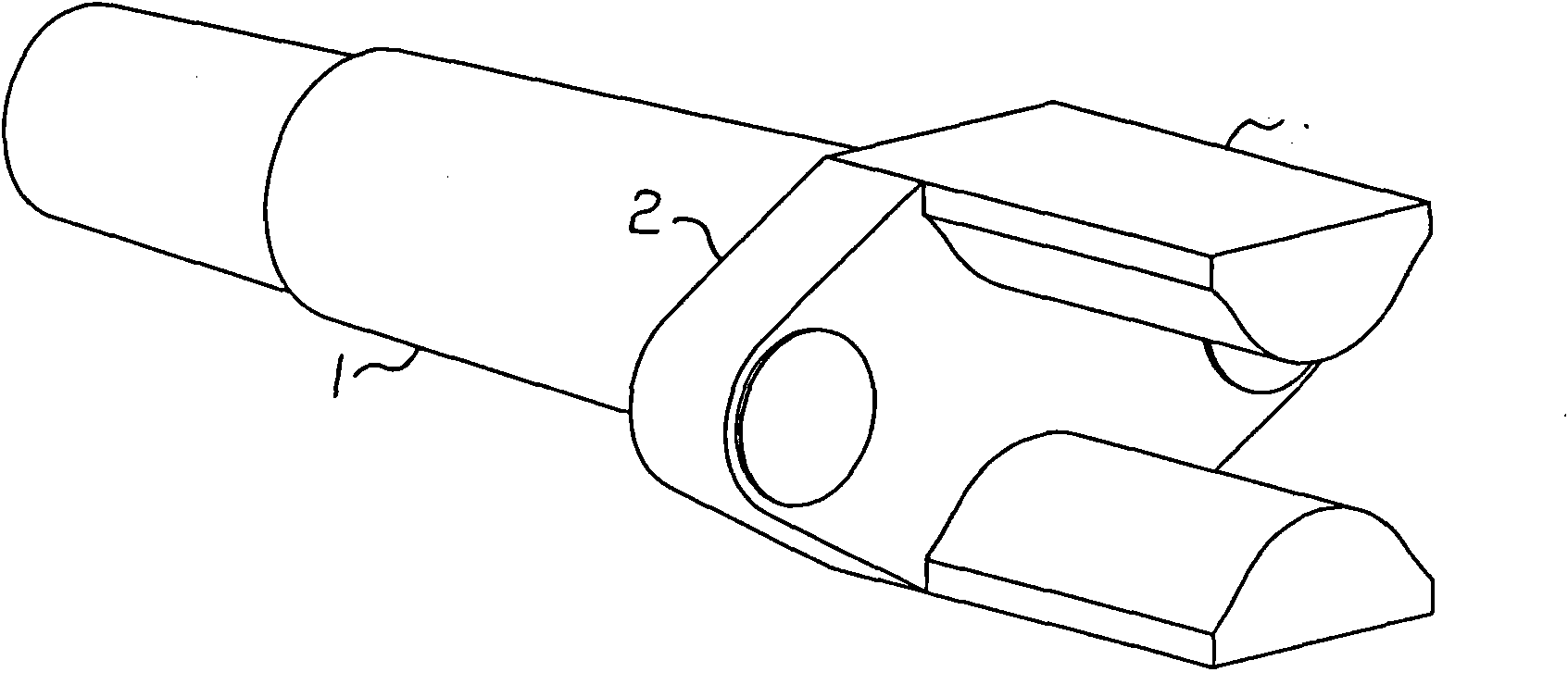

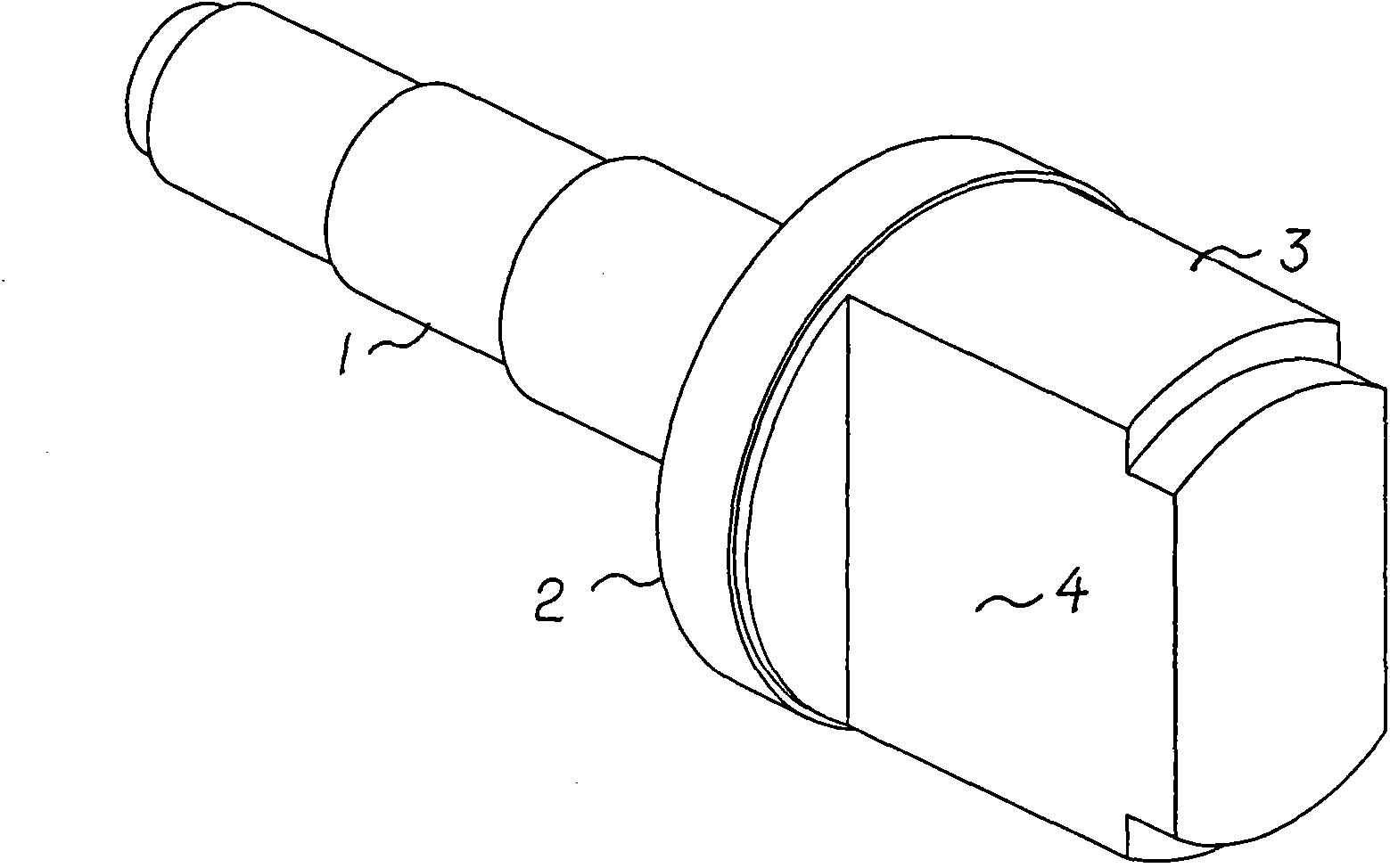

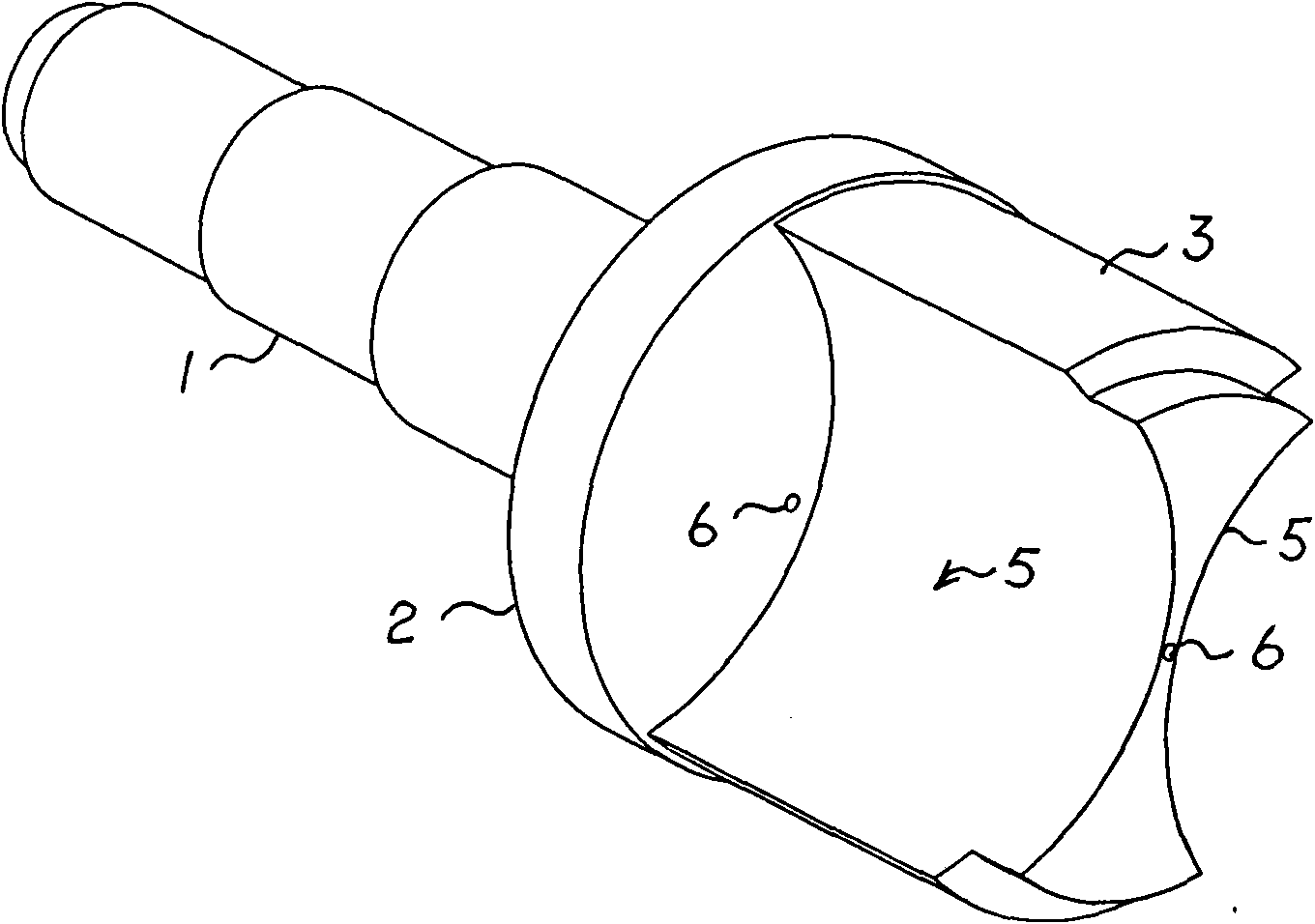

[0048] Such as Figure 7 , a kind of forging and pressing synthetic main shaft for a biomass particle granulator, including a shaft 1 and a protruding first shaft head 8 and a second shaft head 8' located on the pressure roller base plate 2, the shaft 1, the pressure roller The seat plate 2, the first shaft head 8 and the second shaft head 8' are integral forging parts, the pressure roller seat plate 2 is circular, and the cross-section of the first shaft head 8 and the second shaft head 8' is fan-shaped; the pressure roller The outer edge of the seat plate 2 is interference-connected with the ring-shaped pressure roller seat plate outer hoop 10, and the left and right sides of the first shaft head 8 or the second shaft head 8' are respectively provided with a first positioning hole 11 and a second positioning hole 11', the first positioning hole 11 and the second position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com