Ultrasonic reactor based on diffuse sound field

An ultrasonic reactor and diffused sound field technology, applied in the chemical/physical/physical chemical process of applying energy, etc., can solve the problems of uneven sound treatment and low utilization rate of sound energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

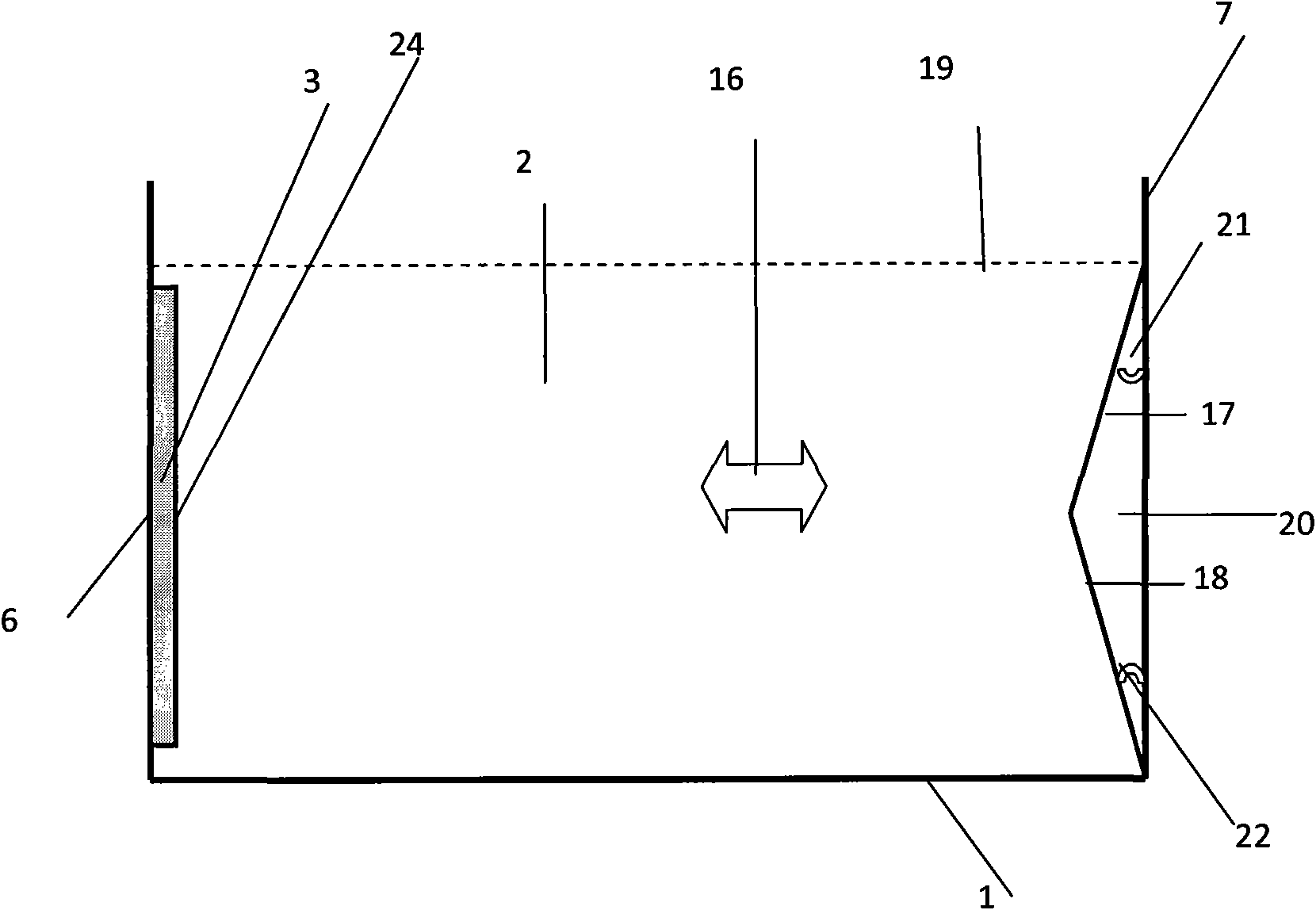

[0019] The ultrasonic reactor of Embodiment 1 is shown in FIG. 1 .

[0020] The ultrasonic reactor rectangular metal box 1 with a submerged flat-plate ultrasonic transducer is equipped with treated water 2 . The ultrasonic transducer 3 (the embodiment adopts an immersion-type flat-panel ultrasonic transducer) is fixed on the first wall 6 . On the second wall 7 facing the first wall 6 there is an acoustic reflector 20 with two acoustic reflection planes 17 and 18 . The two sound reflection planes 17 and 18 are not perpendicular to the incident sound waves from the ultrasonic transducer 3 . A diffuse ultrasonic field 16 is formed in the treated liquid by means of many reflections from the acoustically reflecting planes 17 and 18, the tank 1, the liquid surface 19 and the transducer radiating surface 24.

[0021] The inner dimension of the rectangular metal box 1 is 33.88cm (length) × 26cm (width) × 36cm (height). The height of the water in the box is 31 cm. The size of the i...

Embodiment 2

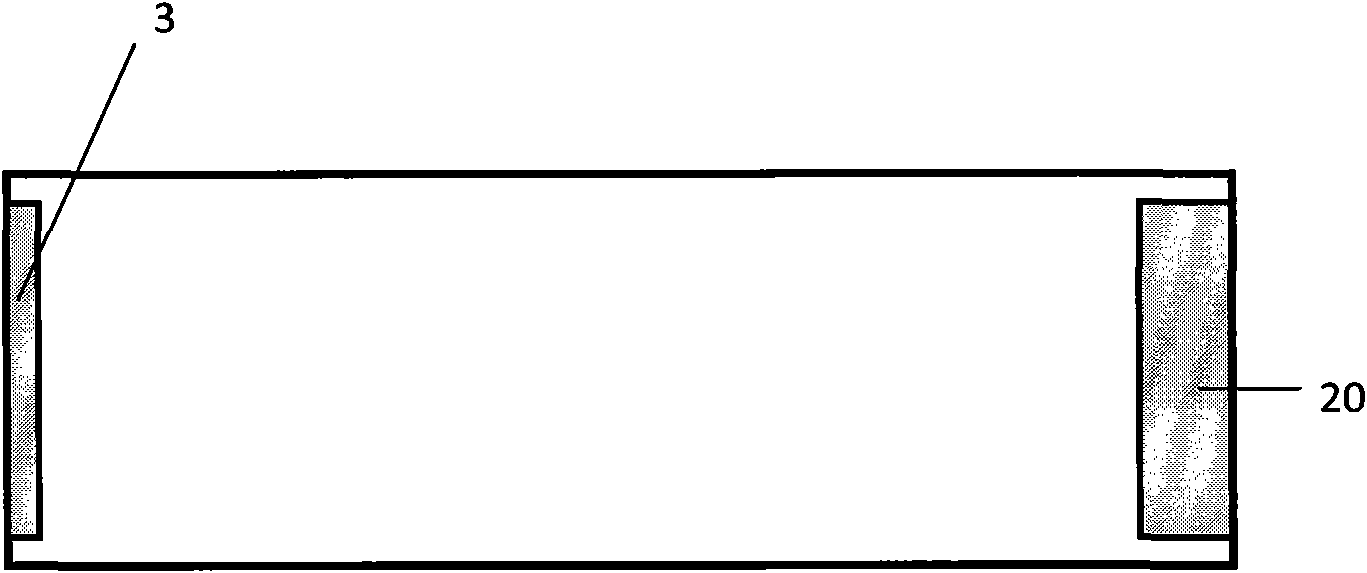

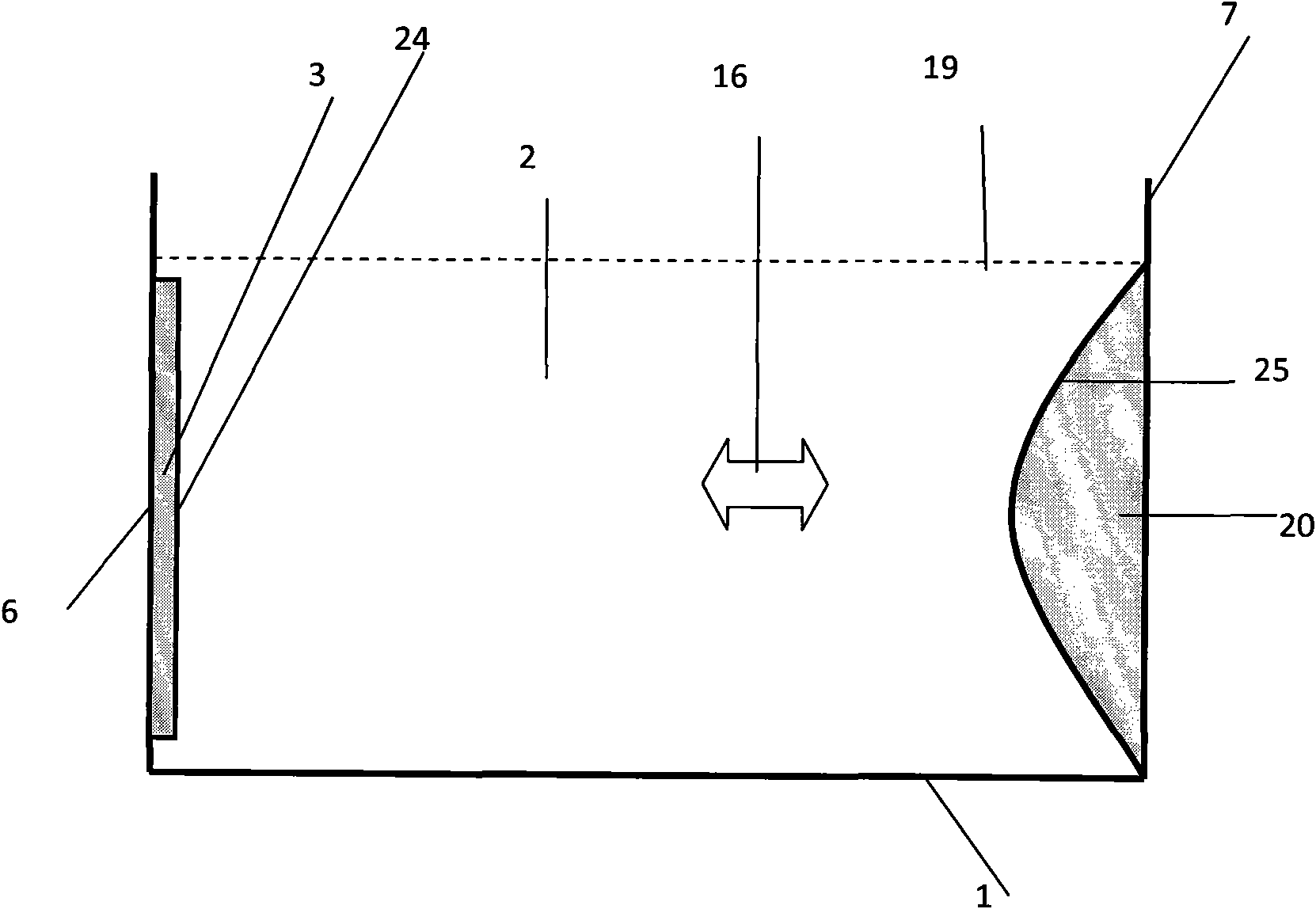

[0023] The ultrasonic reactor of Example 2 is shown in FIG. 2 .

[0024] The ultrasonic reactor rectangular metal box 1 with a submerged flat-plate ultrasonic transducer is equipped with treated water 2 . The ultrasonic transducer 3 (the embodiment adopts an immersion-type flat-panel ultrasonic transducer) is fixed on the first wall 6 . On the second wall 7 facing the first wall 6, an acoustic reflector 20 having a cylindrical sound reflecting surface 25 is provided. The cylindrical sound reflecting surface 25 is not perpendicular to the incident sound wave from the ultrasonic transducer 3 . By virtue of the multiple reflections of the cylindrical acoustic reflection surface 25, the tank 1, the liquid surface 19) and the transducer radiation surface 24, a diffuse ultrasonic field 16 will be formed in the treated liquid.

[0025] The inner dimension of the rectangular metal box 1 is 33.88cm (length) × 26cm (width) × 36cm (height). The height of the water in the box is 31 cm....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com