Variable cross-section standing wave ultrasonic reactor

A technology of ultrasonic reactor and cross-section, which is applied in the direction of chemical/physical/physicochemical processes of energy application, and can solve the problems of low utilization rate of acoustic energy and uneven acoustic treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

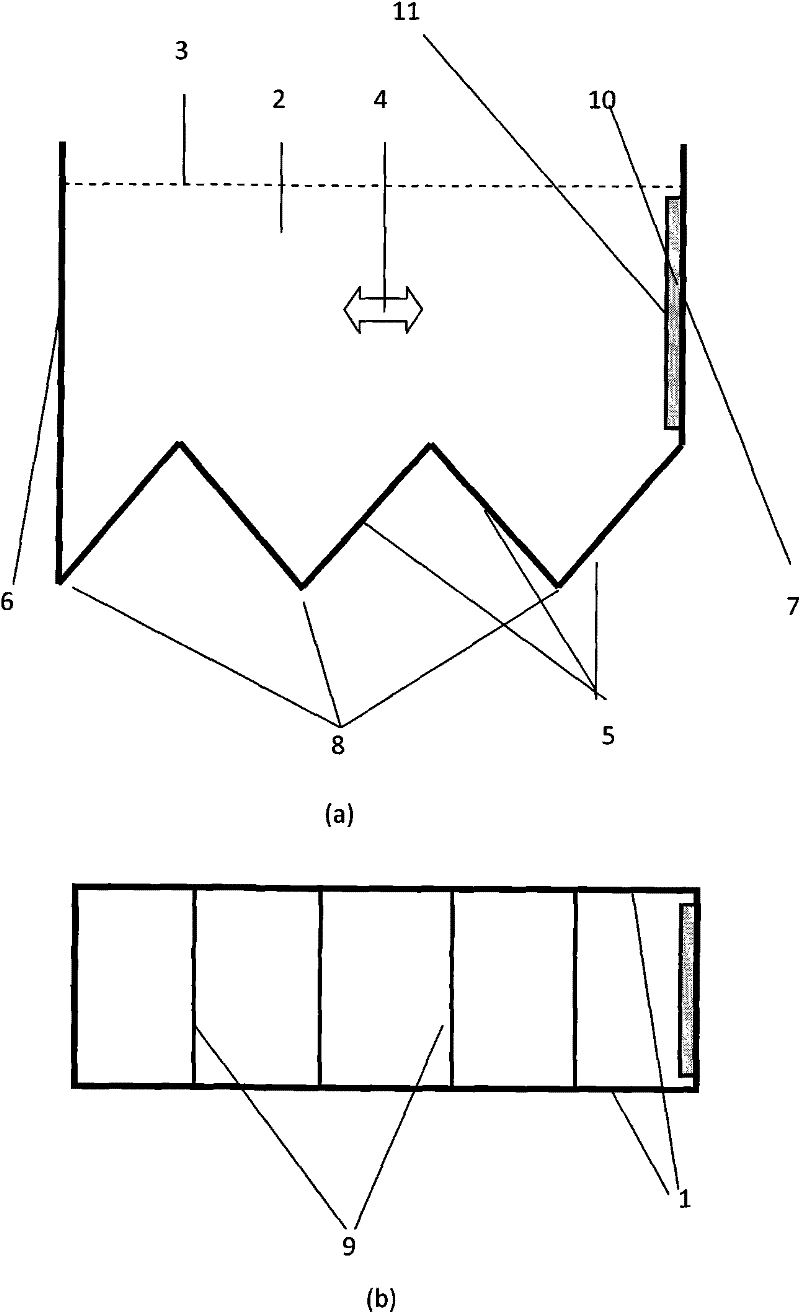

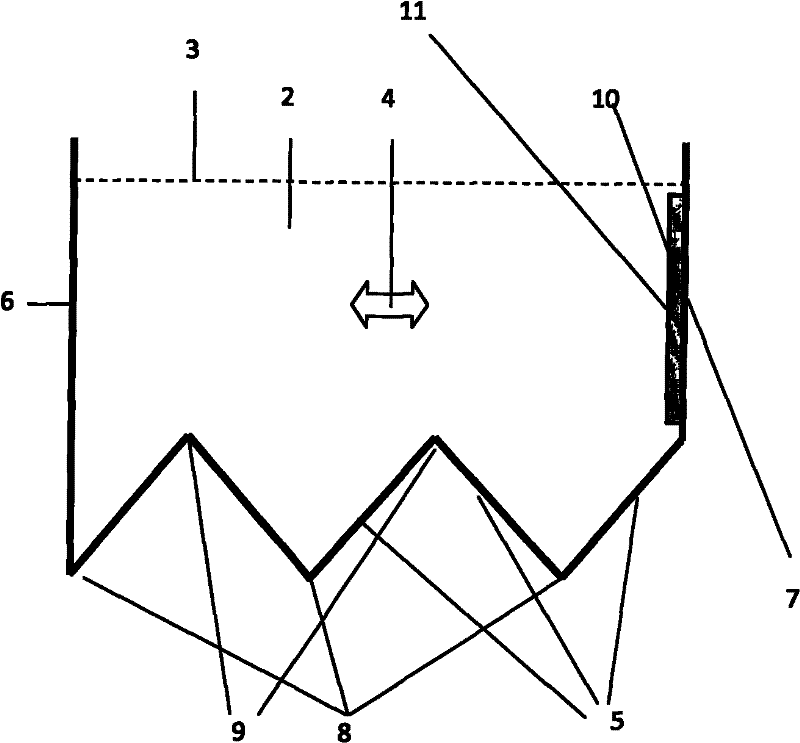

[0016] The variable cross-section standing wave ultrasonic reactor of embodiment one is as figure 1 shown.

[0017] The ultrasonic reactor rectangular metal box with a curved flat bottom is filled with treated water 2 . The ultrasonic transducer 10 is an immersion-type flat-panel ultrasonic transducer, which is fixed on the second wall 7 of the box. The distance between the acoustic radiation surface 11 and the opposite reflective wall surface, that is, the first wall surface 6, is an odd multiple of a quarter wavelength, so there is a gap between the acoustic radiation surface 11 and the first wall surface 6 when the acoustic reactor works. Standing wave sound field.

[0018] The size of the immersed flat panel ultrasonic transducer is 30cm (height)×12cm (width)×1cm (thickness), the working frequency f is 20kHz, and the working voltage is 65Vrms. The length of the rectangular metal box is 10.375cm, and the width is 13cm. The distance h between the bottom surface of the cu...

Embodiment 2

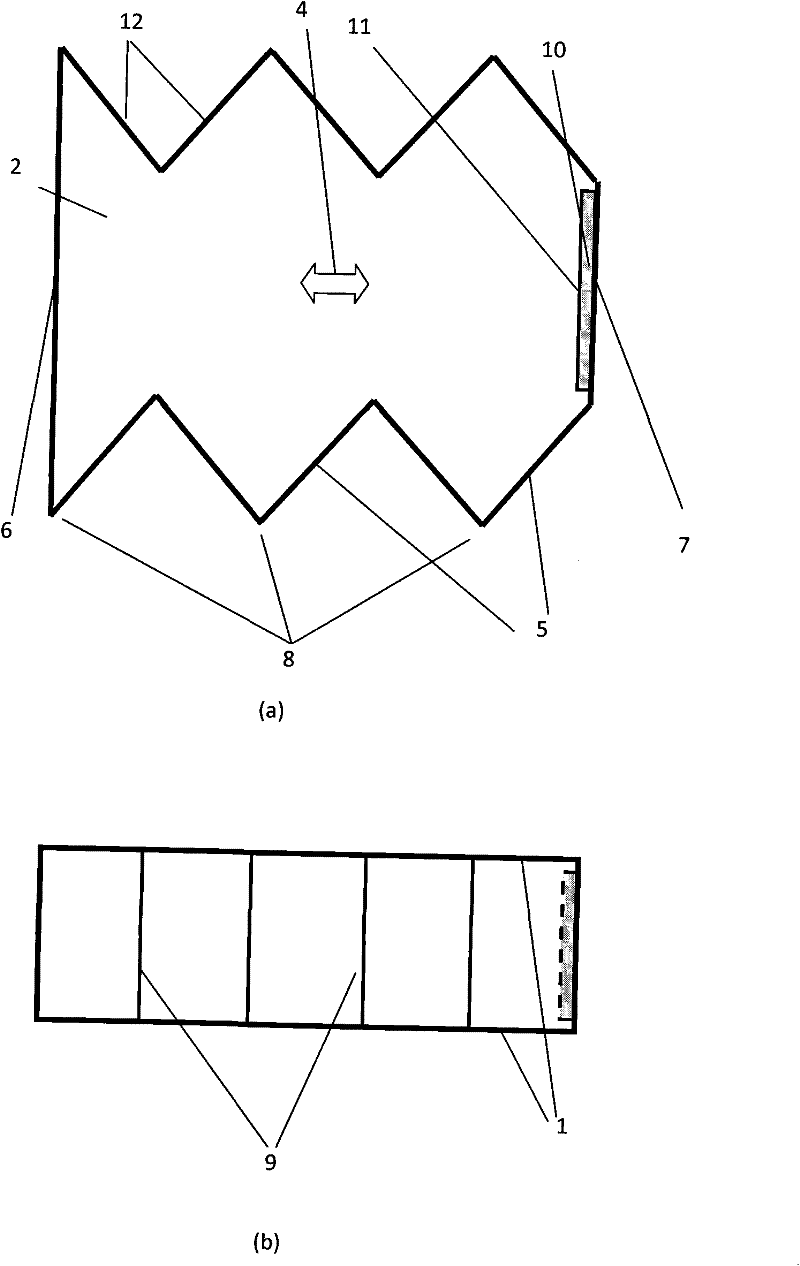

[0020] The variable cross-section standing wave ultrasonic reactor of embodiment two is as figure 2 shown.

[0021] The ultrasonic reactor rectangular metal box with a curved flat bottom surface and a curved flat top surface is filled with treated water. The submerged flat-panel ultrasonic transducer is fixed on the second wall 7 of the box. The distance between the acoustic radiation surface 11 and the opposite reflective wall surface, that is, the first wall surface 6, is an odd multiple of a quarter wavelength, so there is a standing wave between the acoustic radiation surface and the reflective wall surface when the acoustic reactor is working. sound field.

[0022] The size of the immersed flat panel ultrasonic transducer is 30cm (height)×12cm (width)×1cm (thickness), the working frequency f is 20kHz, and the working voltage is 65Vrms. The length of the rectangular metal box is 10.375cm, and the width is 13cm. The distance h between the bottom surface and the top sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com