Wide polar plate electrostatic precipitation module

An electrostatic precipitator and electrode plate technology, applied in the field of wide-plate electrostatic precipitator modules, can solve the problems of material and energy waste, large size of electrostatic precipitator modules, etc., and achieve the effects of low voltage, reduced volume, and small current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

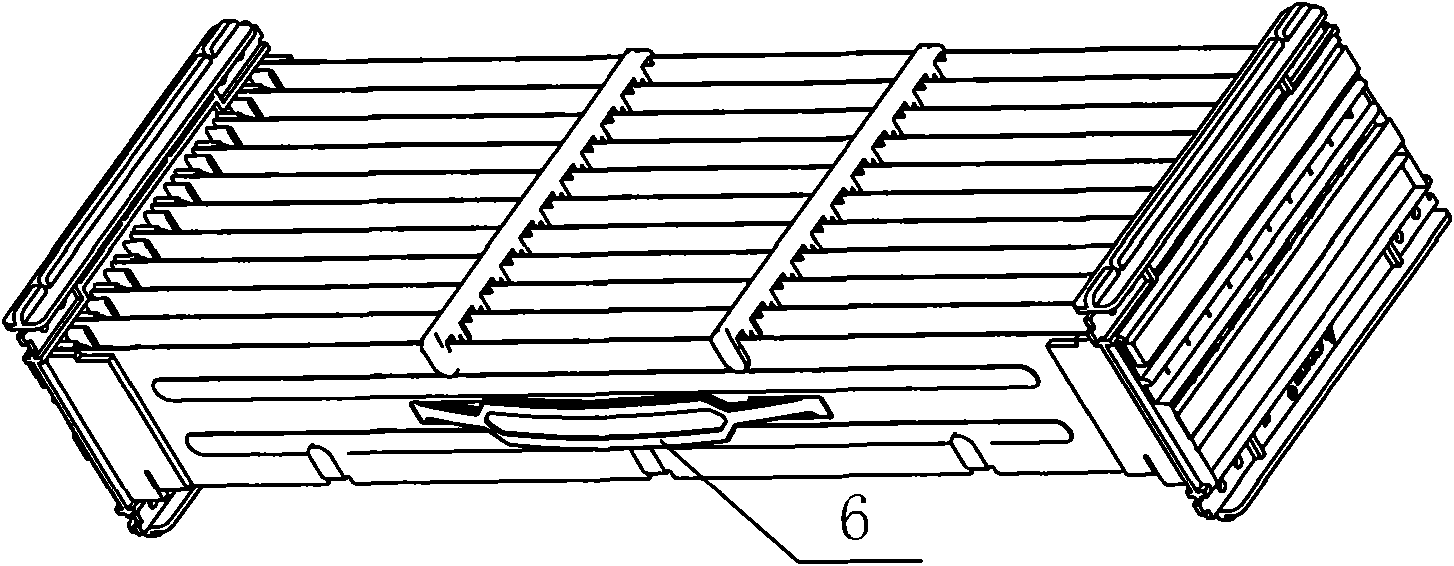

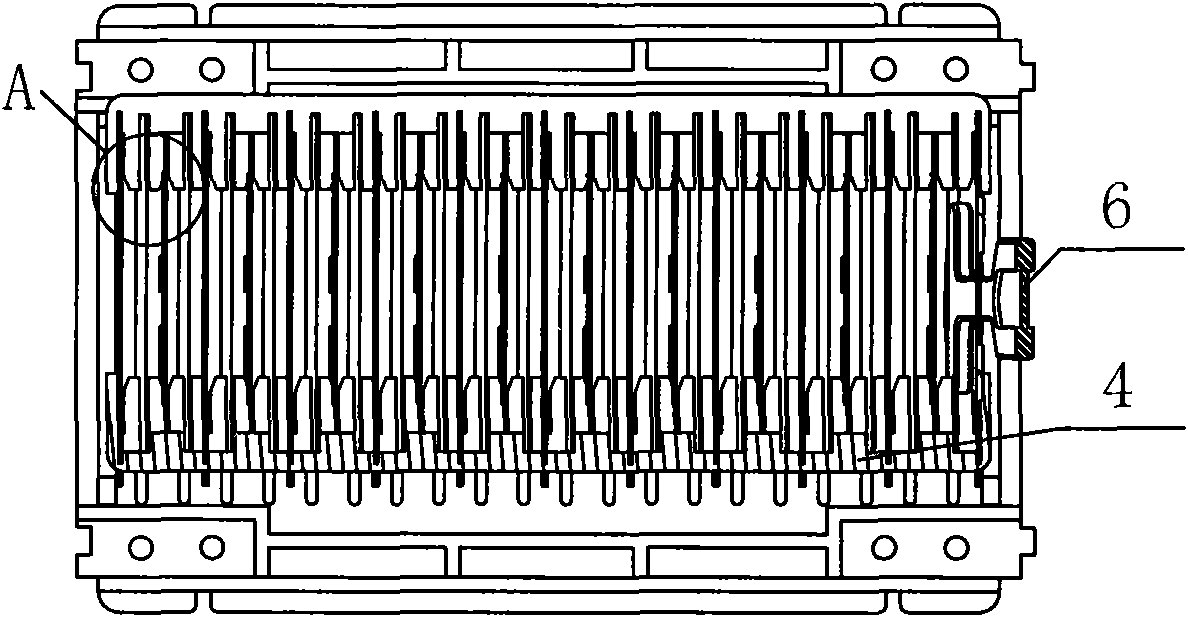

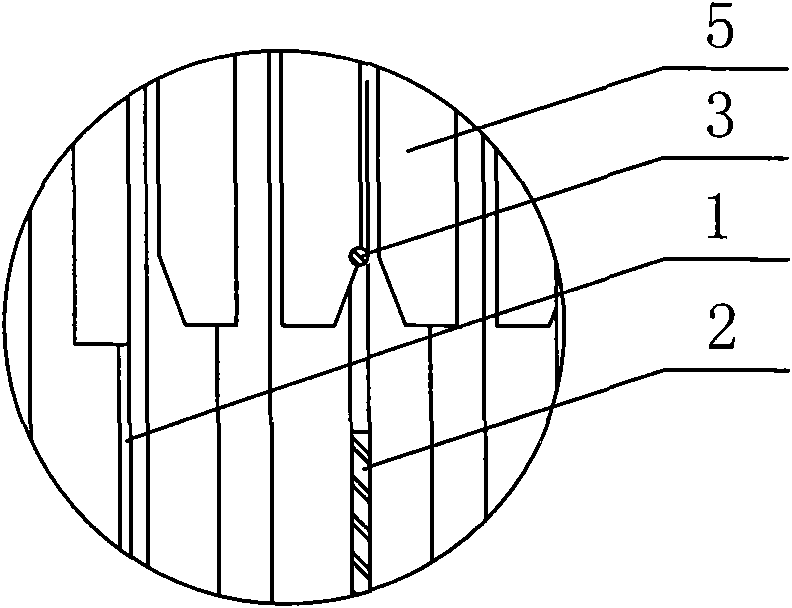

[0016] Such as Figure 1-3 As shown, in this embodiment, the wide plate electrostatic precipitator module is installed in the purifier as the core electrostatic precipitator component, mainly including the positive wide aluminum plate 1, the negative narrow aluminum plate 2, the high-energy ion wire 3, and the terminal conductive fixed aluminum strip 4 . Plastic fixing assembly 5, the positive wide aluminum plate 1 and the negative narrow aluminum plate 2 are arranged to cross each other, the high-energy ion wire 3 is crimped on the negative narrow aluminum plate 2, and the positive wide aluminum plate 1 and the negative narrow aluminum plate 2 are inserted into the plastic fixing assembly 5, the slots are designed according to the width and thickness of the positive wide aluminum plate 1 and the negative narrow aluminum plate 2, the positive wide aluminum plate 1 and the negative narrow aluminum plate 2 are separated by the standard distance designed on the plastic fixing part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com