Dual-cylinder carriage and combined oilstone clamp mechanism of bearing roller super-precision grinding machine

A bearing roller, fine grinding technology, applied in the field of grinding machines, can solve the problems of time-consuming and laborious installation, failure of grinding function, affecting production efficiency, etc., and achieve the effect of reducing production cost, improving production efficiency, and quick and convenient replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings, and this manufacturing technique is very clear to those skilled in the art.

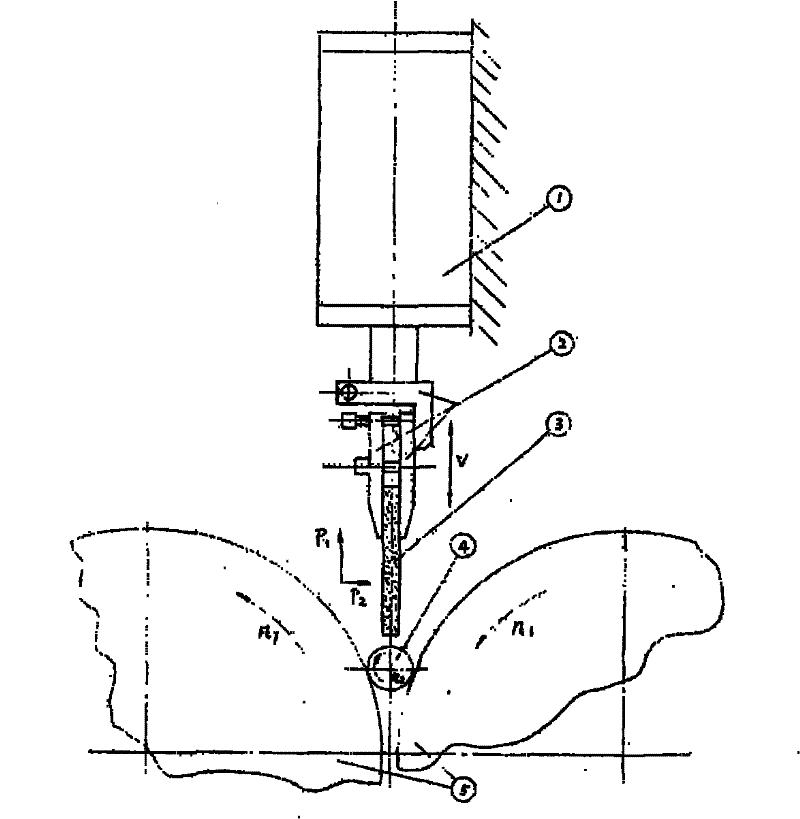

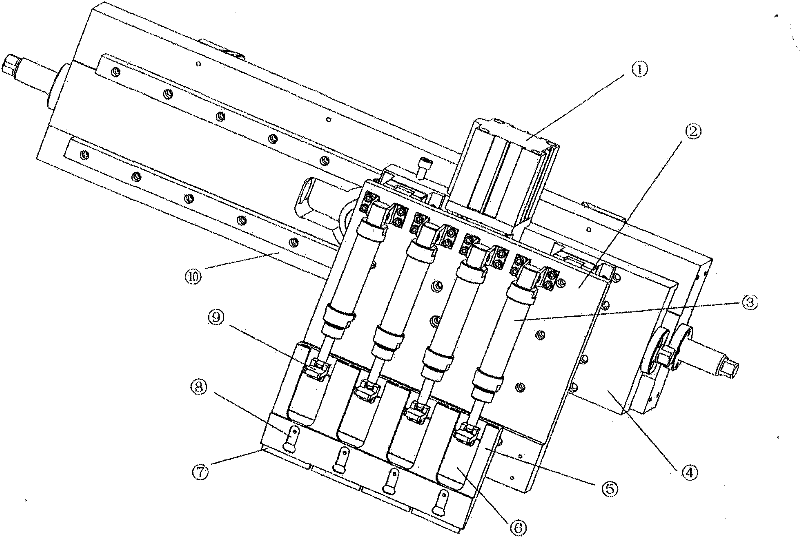

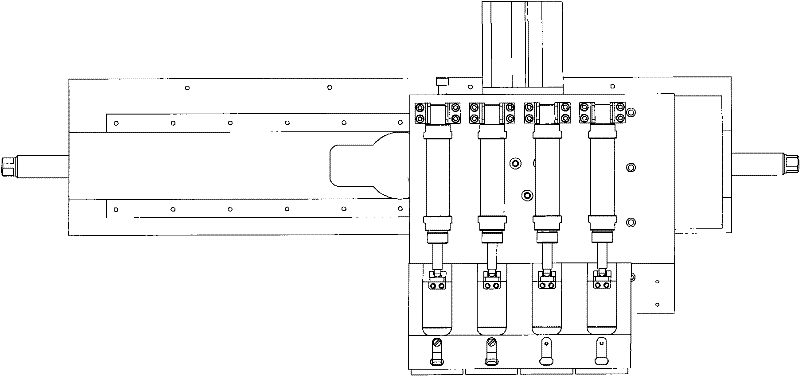

[0025] see Figure 2 to Figure 5 , the ultra-fine grinding machine is provided with a double-cylinder carriage and a combined oilstone clamping mechanism, and the double-cylinder carriage includes a fast-feed cylinder pair (1), an upper and lower carriage pair (2), and a working feed cylinder pair (3 ) form; the combined whetstone clip mechanism is composed of a whetstone clip body (5), a whetstone presser (6), a whetstone presser head (9), and a flexible compression spring (8); The oscillating carriage pair (4), the back of the upper and lower carriage pair (2) is provided with a pair of linear guide rails connected with the oscillating carriage pair (4), the upper and lower carriage pairs (2) slide up and down, and the oscillating carriage pair (4) goes up and down. A quick-feed cylinder pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com