Mud-cleaning bucket machine special for underground railway channel

A chain bucket machine and tunnel technology, applied in tunnels, conveyors, mining equipment and other directions, can solve the problems of poor working environment, long working time, and increased safety control work for workers, and achieve easy construction management and reduce mud removal costs. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

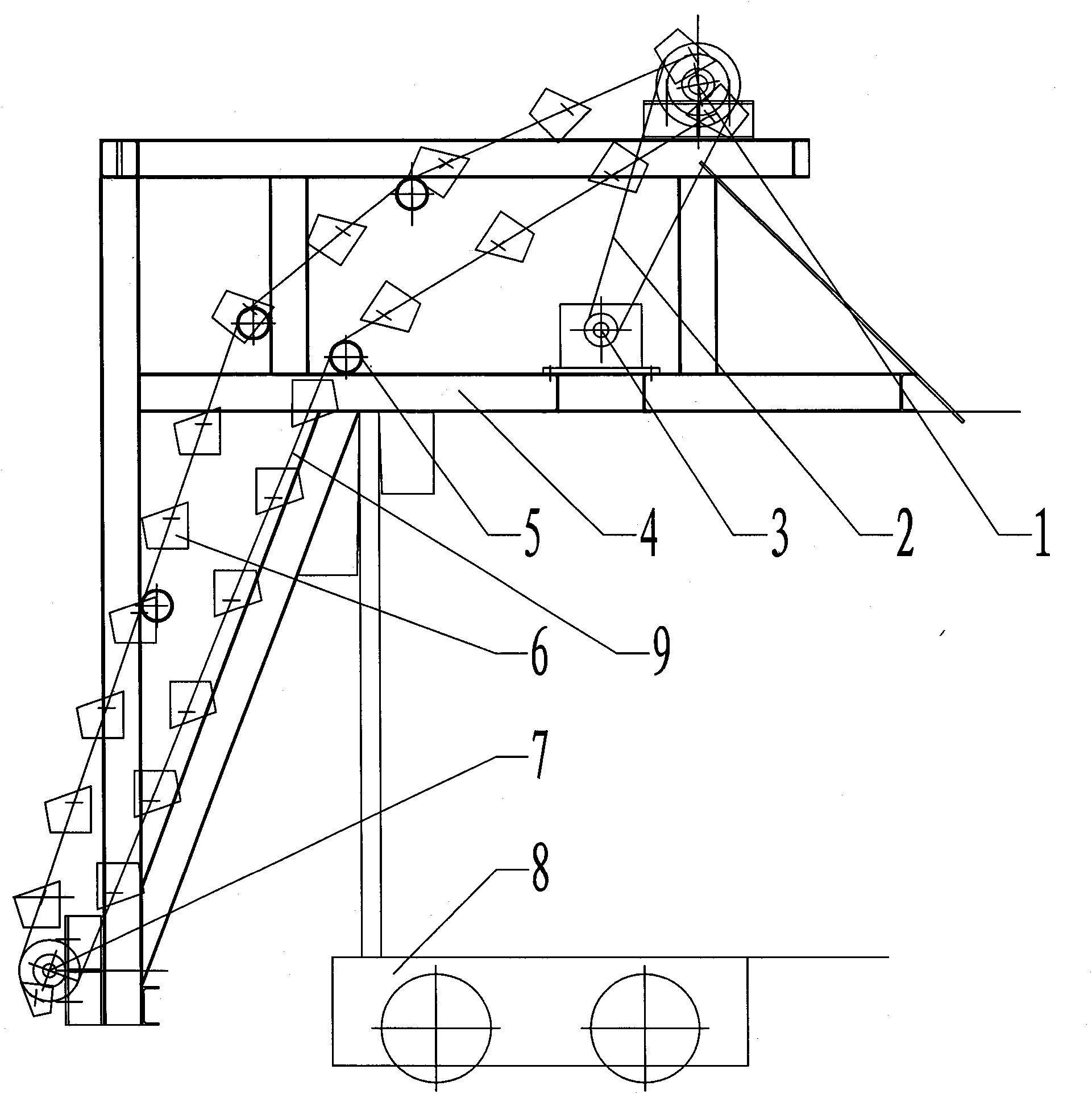

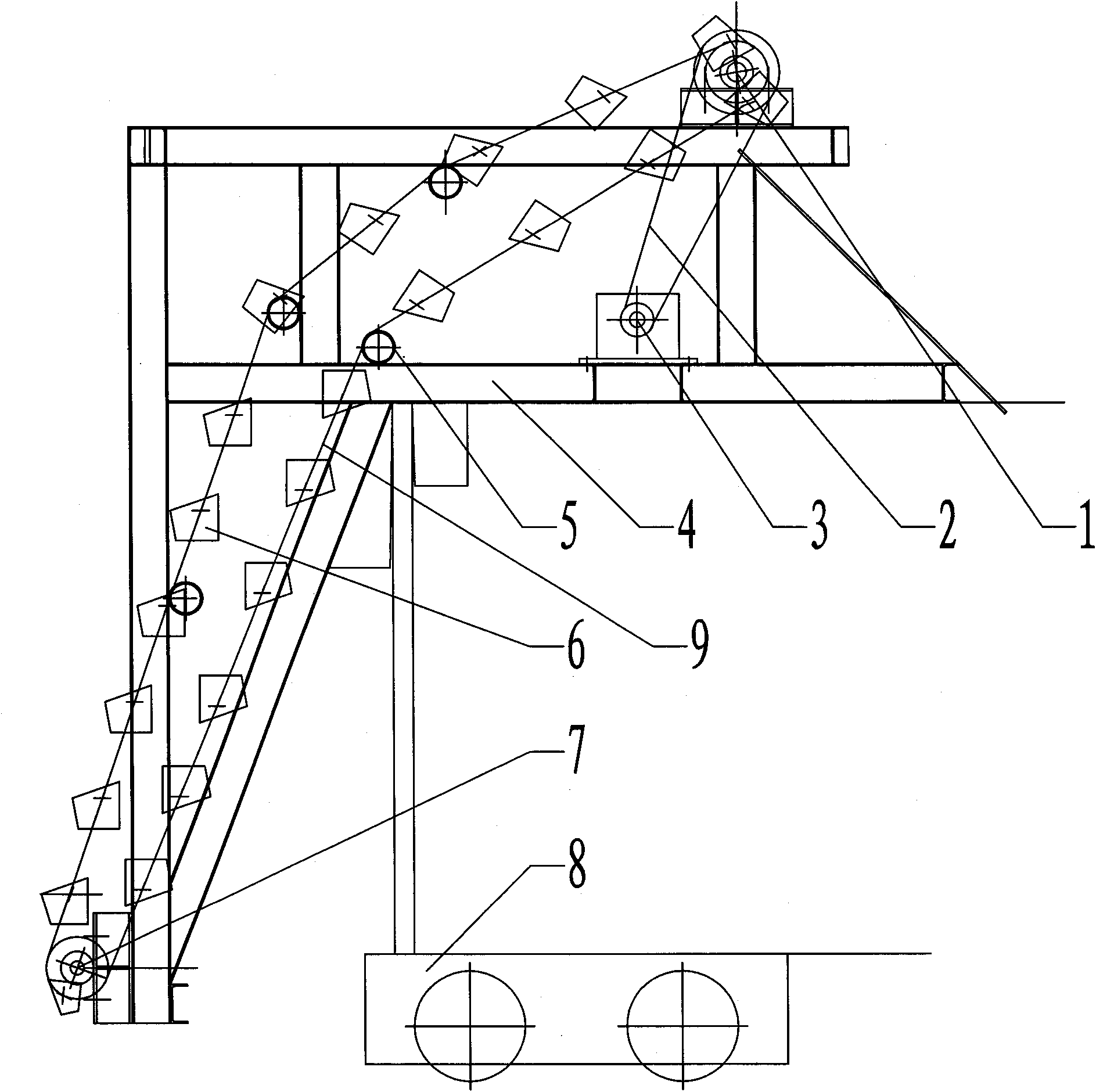

[0008] Such as figure 1 As shown, the special mud cleaning chain bucket machine for subway tunnels installs the pin wheel reducer 3 for driving, the main driving sprocket 1, the driven sprocket 7 and the guide wheel 5 on the frame 4 according to the positions shown in the figure, and the main driving chain 2 Installed on the output shaft gear of the drive pin wheel reducer 3 and the main drive sprocket 1, the transmission chain 9 is installed on the main drive sprocket 1, the driven sprocket 7 and the guide wheel 5, and the mud buckets 6 are positioned at equal intervals Installed on the transmission chain 9, the muck box 8 is connected to the frame 4; before the mud cleaning operation, the battery car is hung with a section of earth truck, parked at the excavation position at the wellhead, and the special chain bucket machine is installed on the back of the earth truck with a door crane. On the side wall at the back end of the soil box; the power plug of the special chain buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com