Novel aircraft environmental control system using high-pressure dehumidifying membrane component

A technology for controlling system and environment, applied in applications, air conditioning systems, household heating, etc., can solve the problem of reducing the membrane area by the transmission rate, and achieve the effects of avoiding cooling loss, high expansion ratio, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

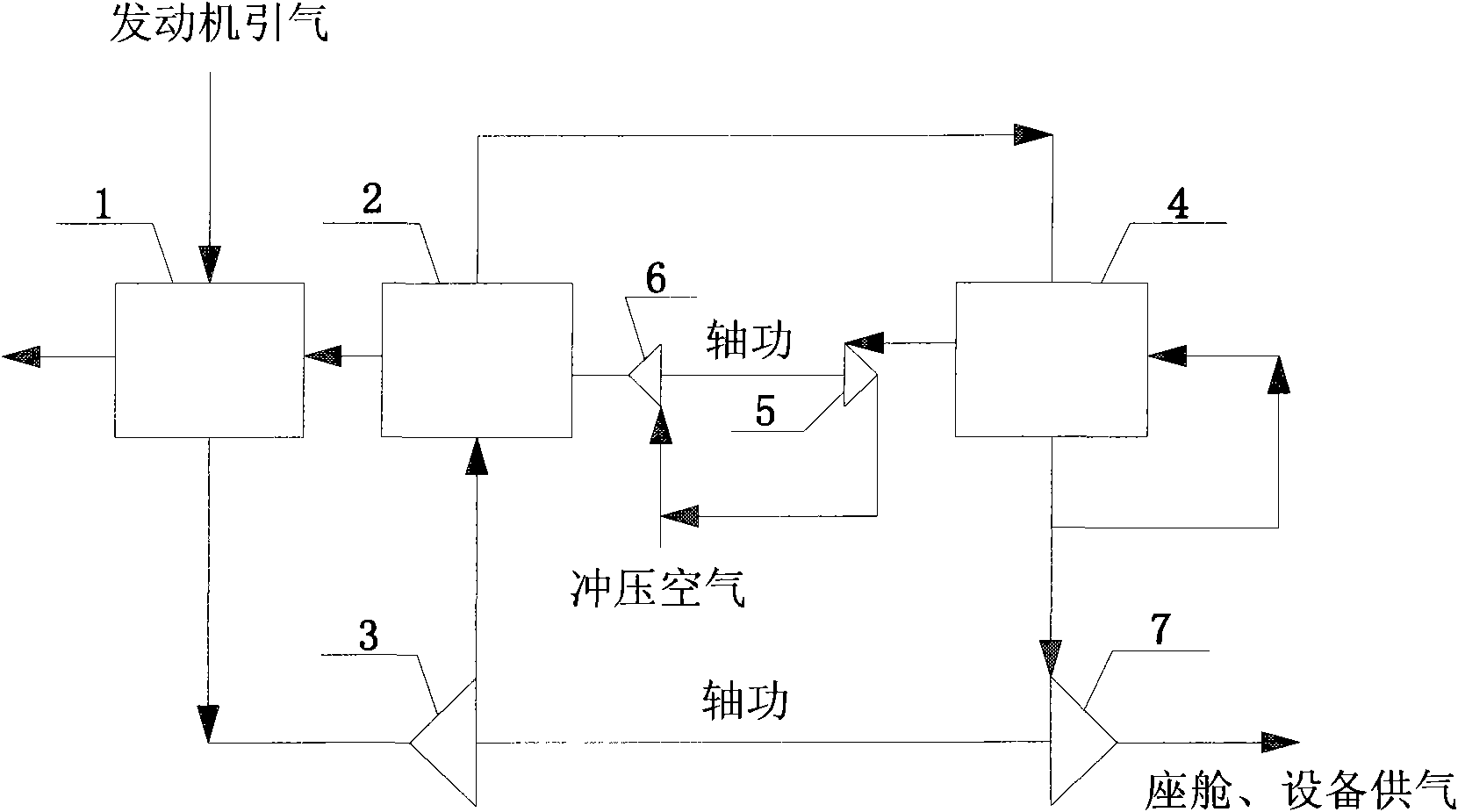

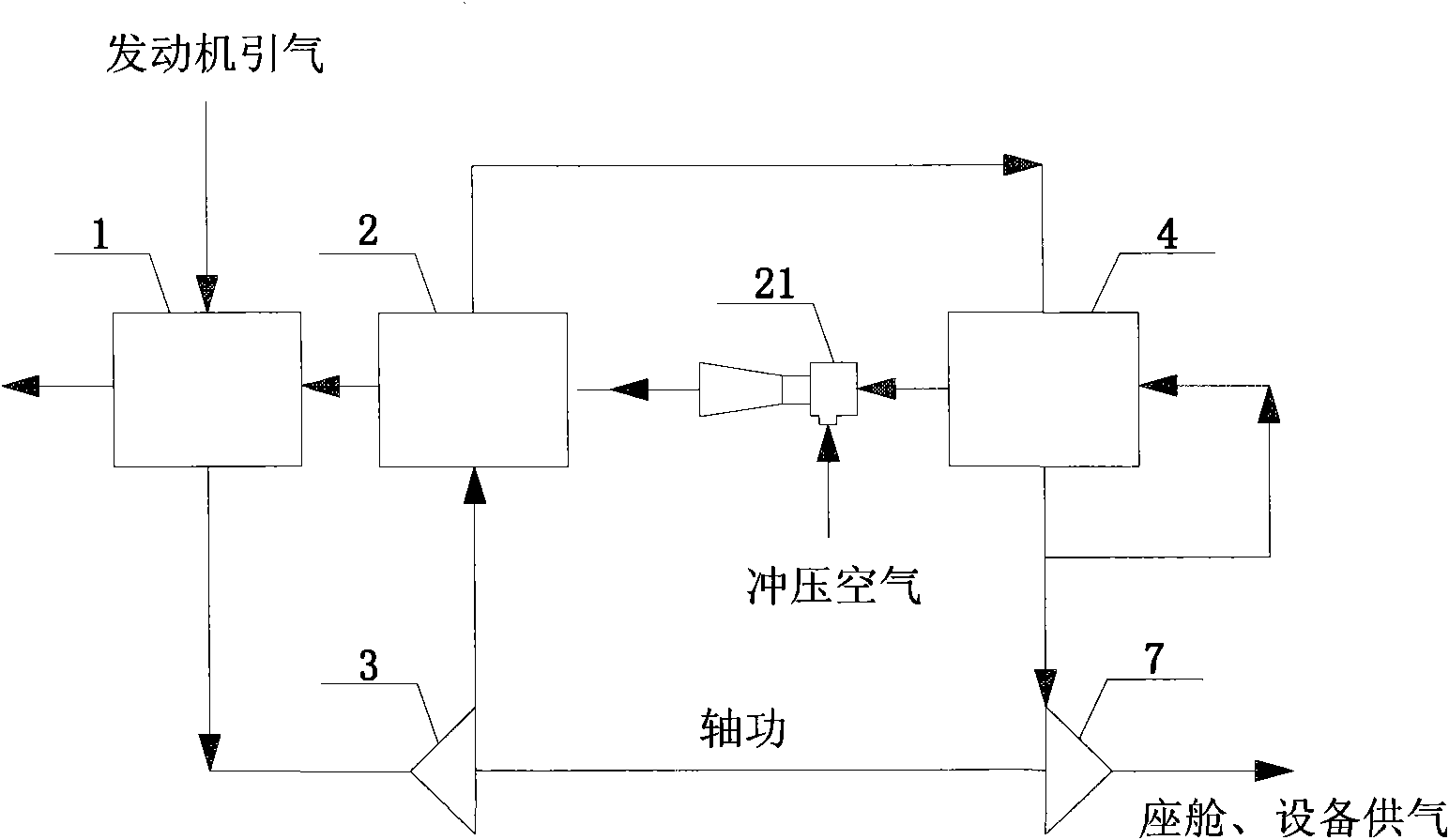

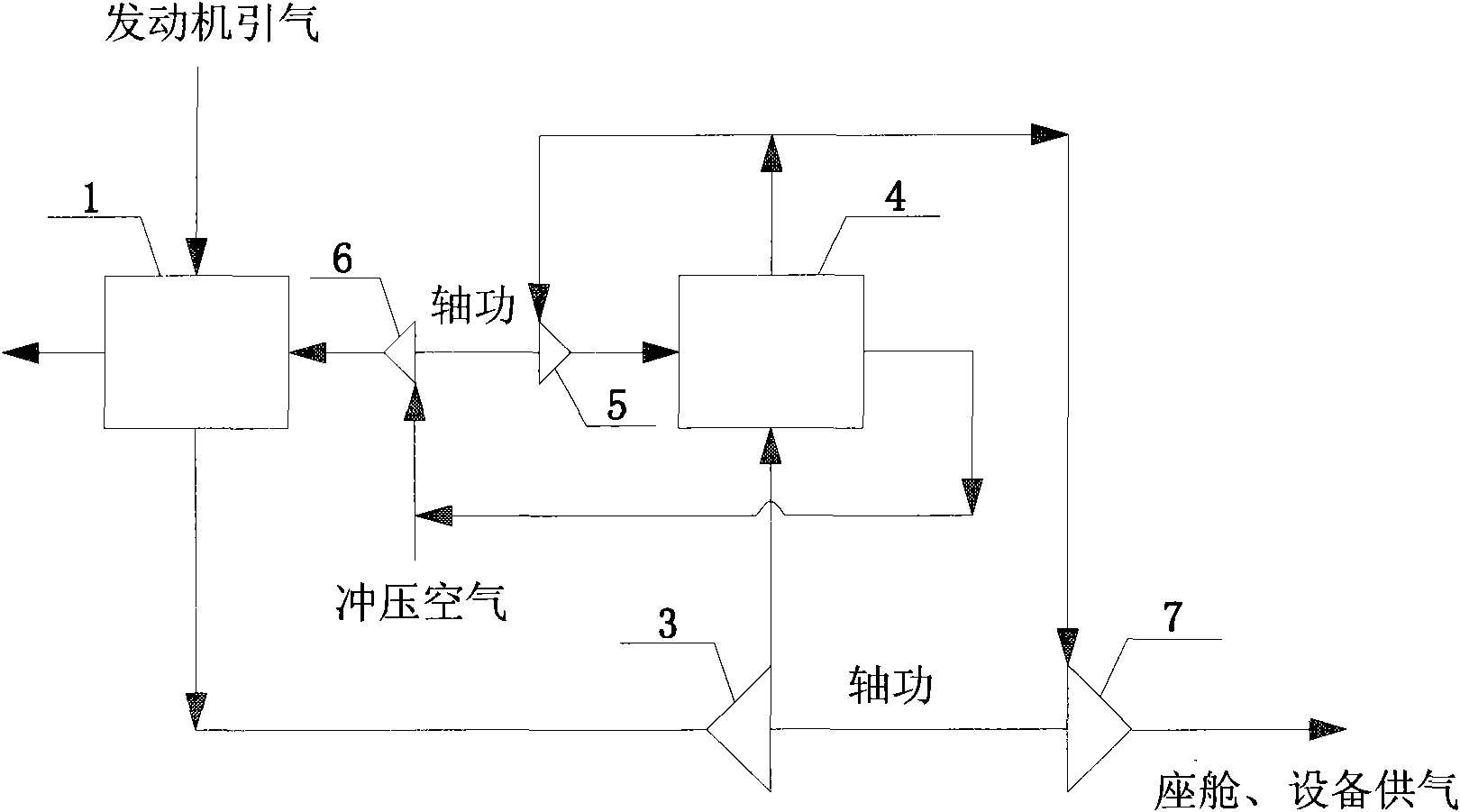

[0018] Such as figure 1 The illustrated embodiment of the two-wheel step-up membrane high-pressure dehumidification system of the present invention includes: a primary heat exchanger 1, a secondary heat exchanger 2, a compressor 3, a membrane dehumidification heat exchanger 4, a small turbine 5, and a fan 6 and the big turbo 7.

[0019] The operation mode of the system is: the engine bleed air enters the compressor 3 after being cooled by the primary heat exchanger 1. The stage heat exchanger 2 is cooled, and enters the membrane dehumidification heat exchanger 4 for dehumidification and heat exchange, and finally expands and cools through the turbine 7 to supply the cabin or equipment compartment. The purge airflow of the membrane dehumidification heat exchanger 4 is part of the dehumidified air at the outlet of the membrane dehumidification heat exchanger 4. The purge airflow can take away the water vapor on the permeation side of the membrane dehumidification heat exchanger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com