Engine test running power output tooling

A power output and engine technology, which is applied in the field of power output tooling for passenger car testing, can solve problems such as large vibration and no guarantee of coaxiality, and achieve the effects of reducing burnout, stable power output and reducing vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

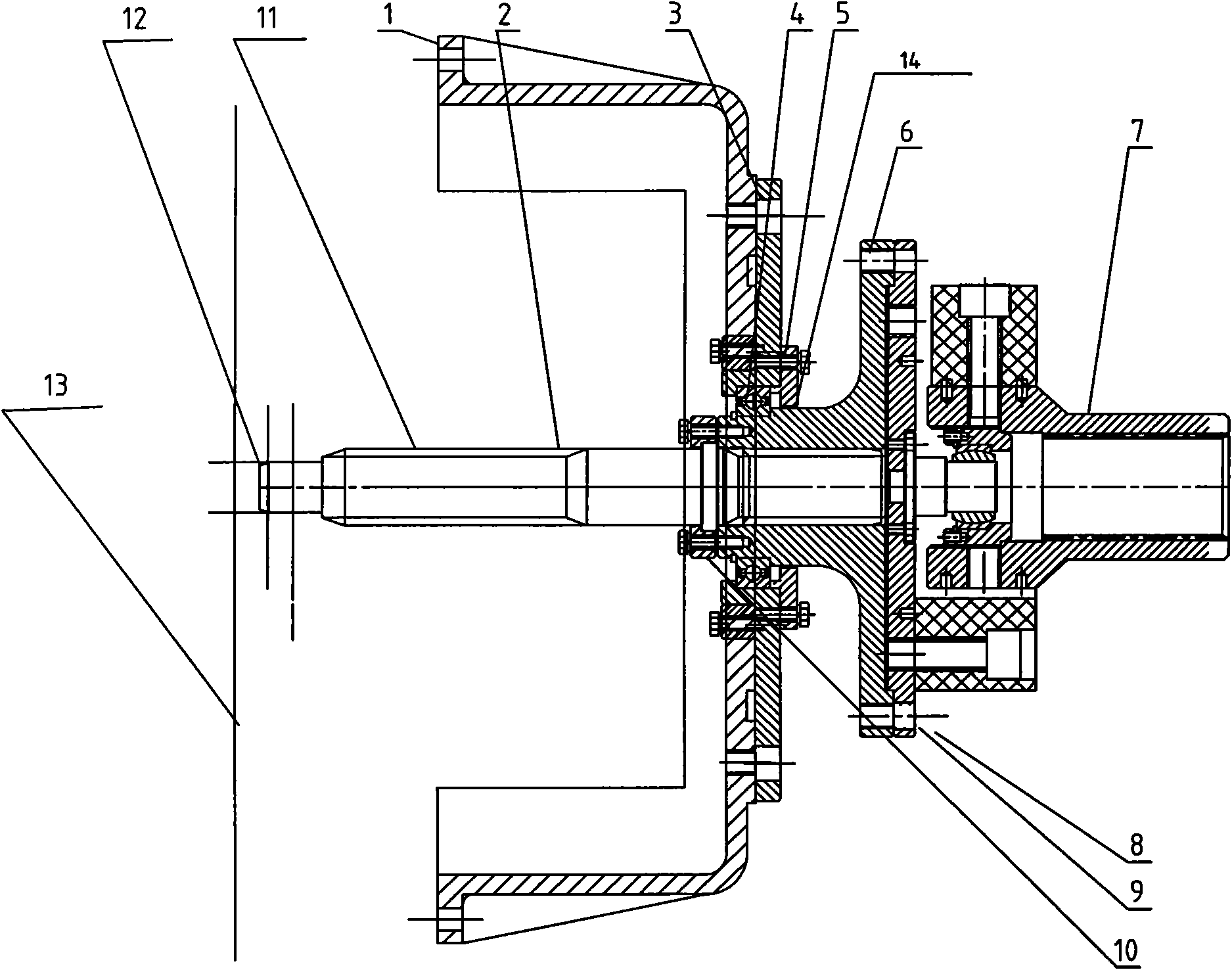

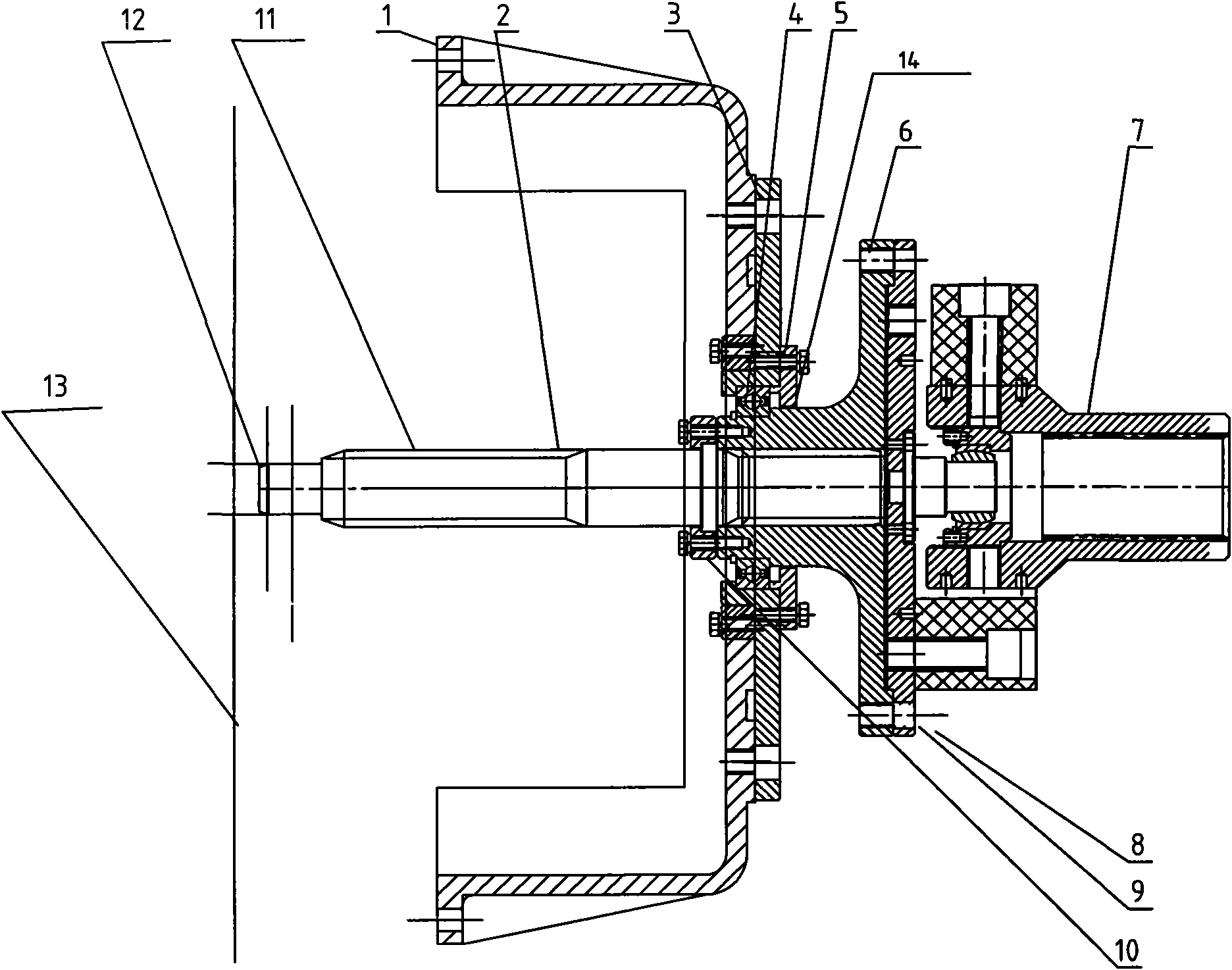

[0015] figure 1 It is a structural schematic diagram of an embodiment of the engine test power output tooling of the present invention, as figure 1 As shown, the tooling of the present invention includes a transmission clutch housing 1, a transmission spline shaft 2, a coupling joint 6 and an elastic coupling 7, one end of the transmission spline shaft 2 is connected to one end of the elastic coupling 7, and the clutch housing 1 Set on the transmission spline shaft 2, the coupling joint 6 is clamped between the transmission spline shaft 2 and the elastic coupling 7, the transmission spline 11 located at the other end of the transmission spline shaft 2 and the rear end of the engine crankshaft The clutch driven disc cooperates with the transmission, and the small spline head 12 located at the top of the other end of the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com