Multi-generator set multi-pulse rectifying method

A generator set and generator set technology, which is applied in the direction of irreversible AC power input conversion to DC power output, etc., can solve the problems of direct drive system volume, weight and cost, large rectification output pulsation, and large filter components. Achieve stable DC voltage, reduce circuit loss, and reduce capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

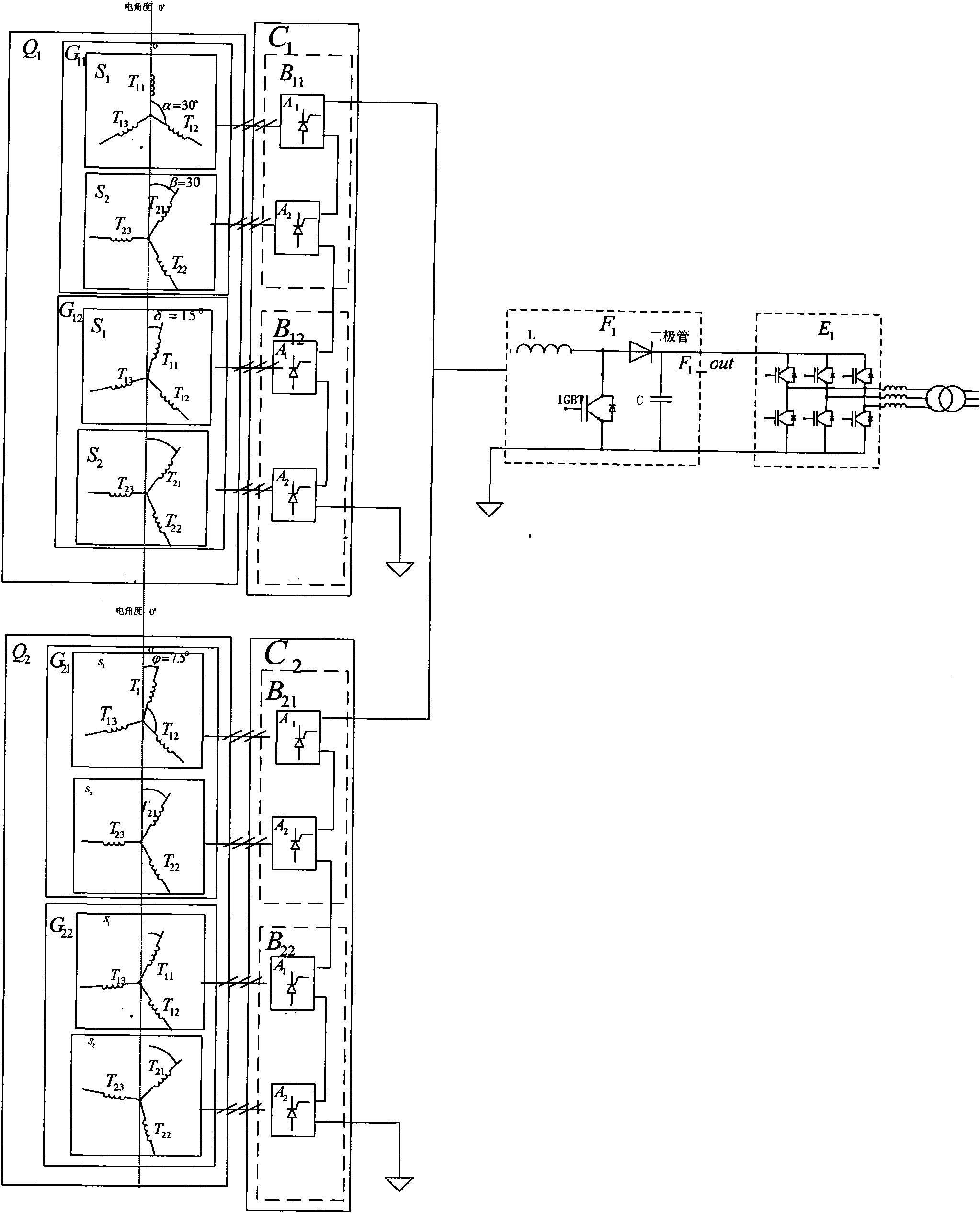

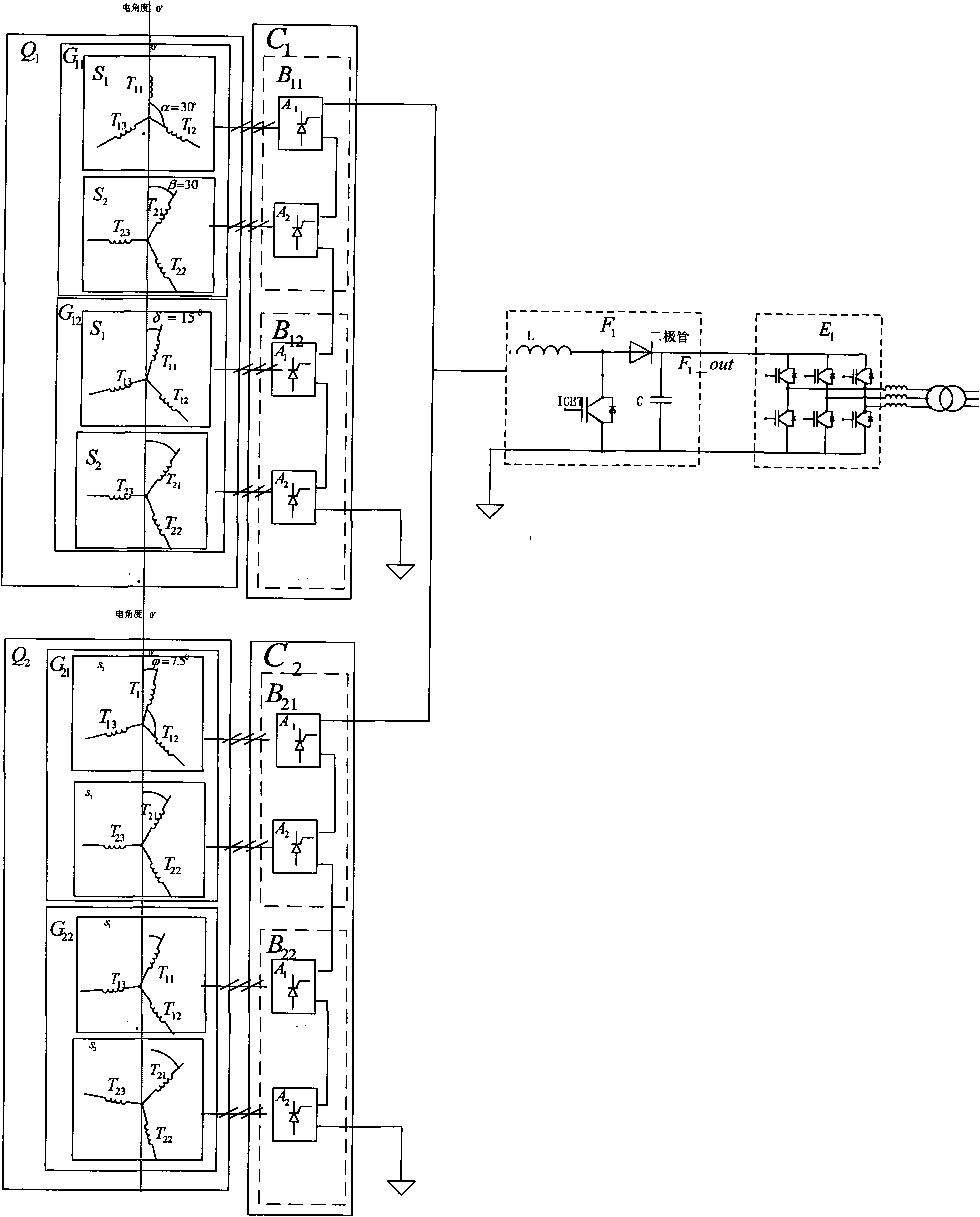

[0014] refer to figure 1 , in this example, there are 4 generators G11, G12, G21, G22 that have the same structure and capacity, and are operated synchronously under mechanical structure constraints (such as using a rotating gear to mesh with the gear of the generator). Divide the 4 generators into 2 groups on average Q1, Q2, (ie M=2), each generator set includes 2 generators (ie N=2).

[0015] Let each generator be a six-phase generator, taking the first generator G11 as an example, as figure 1 shown. The total number of internal windings is F=6, and the 6 windings are evenly divided into two groups S1 and S2 (ie J=2), each group of windings is a rectifier unit, and each group has 3-phase windings (ie K=3).

[0016] The windings in the generator meet the following electrical angle requirements: the electrical angle between the windings of the same rectifier unit is α=360° / K=120°, and the electrical angle between the windings T11, T12, and T13 of the first rectifier unit S1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com