Tower type photovoltaic tracking power generation system

A photovoltaic and tower-type technology, applied in the field of tower-type photovoltaic tracking power generation system, can solve the problems of high cost, low tracking accuracy, high failure rate, etc., and achieve the effect of improving power generation capacity and overall structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

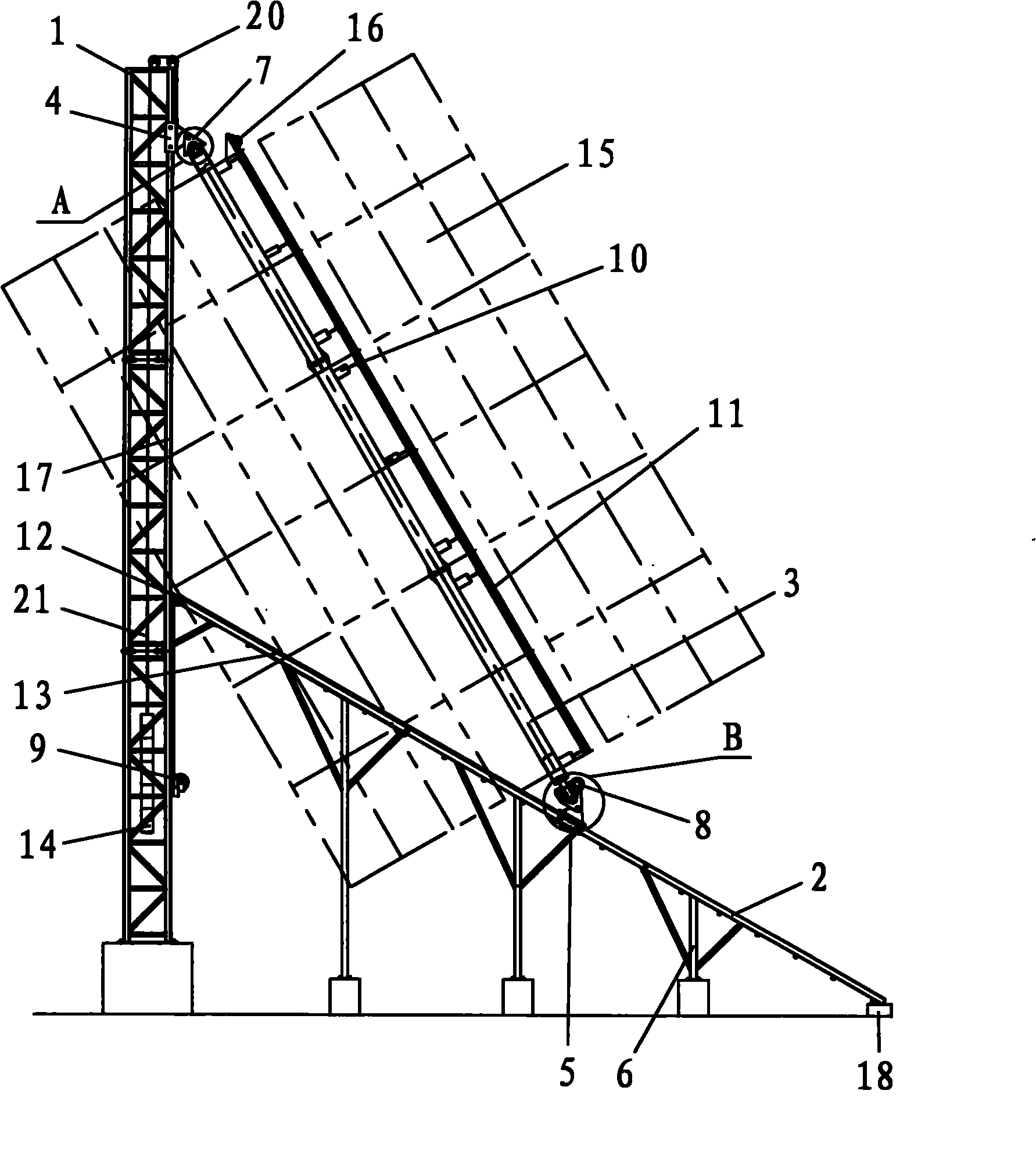

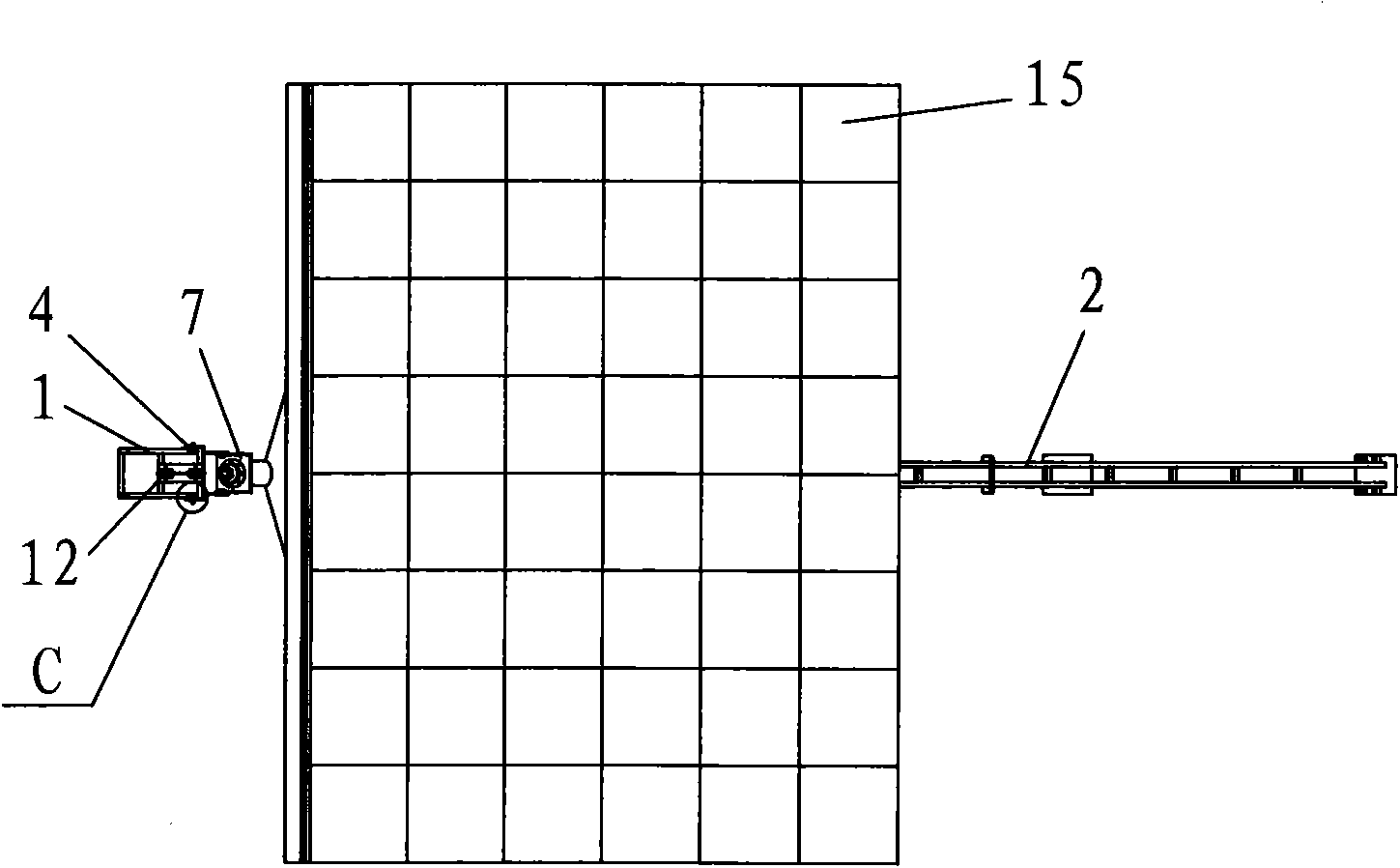

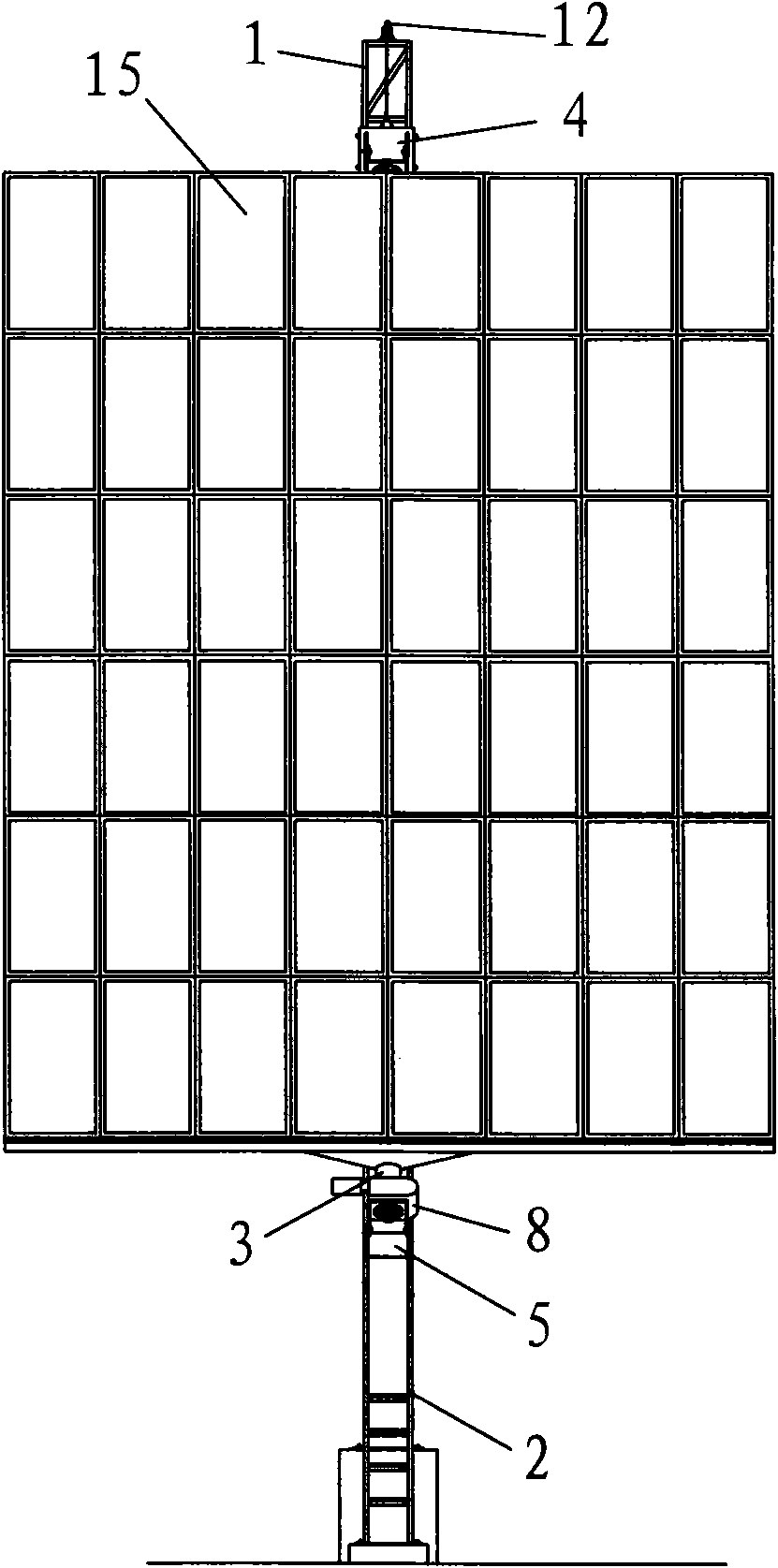

[0021] Such as Figure 1 to Figure 6 As shown, the tower type photovoltaic tracking power generation system of the present invention includes a vertical guide rail 17, a latitude tracking guide rail 2, a driving device, a battery panel rotation shaft 3, and a battery panel fixing bracket 11 is fixedly arranged on the panel rotation shaft 3, and a solar panel 15 is fixedly installed on the battery panel fixing bracket 11. The vertical guide rail 17 is fixedly installed on the tower frame 1, one end of the latitude tracking guide rail 2 is fixedly installed on the tower frame 1, and the other end is fixedly installed on the ground cement base 18, and the latitude tracking guide rail 2 is installed obliquely. The angle is 30 degrees.

[0022] A vertical skateboard frame 4 for sliding along the guide rail is set on the vertical guide rail 17, and an inclined skateboard frame 5 for sliding along the guide rail is set on the latitude tracking guide rail 2. The upper ends of 3 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com