Inner glue and rubber mixed material for high-performance steel wire-wound hydraulic rubber tubes and preparation method thereof

A technology of steel wire winding and mixed materials, which is applied in the field of rubber materials, can solve the problems of liquid leakage, inner rubber pinholes, and low performance, and achieve the effects of simple preparation process, strong pulse performance, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

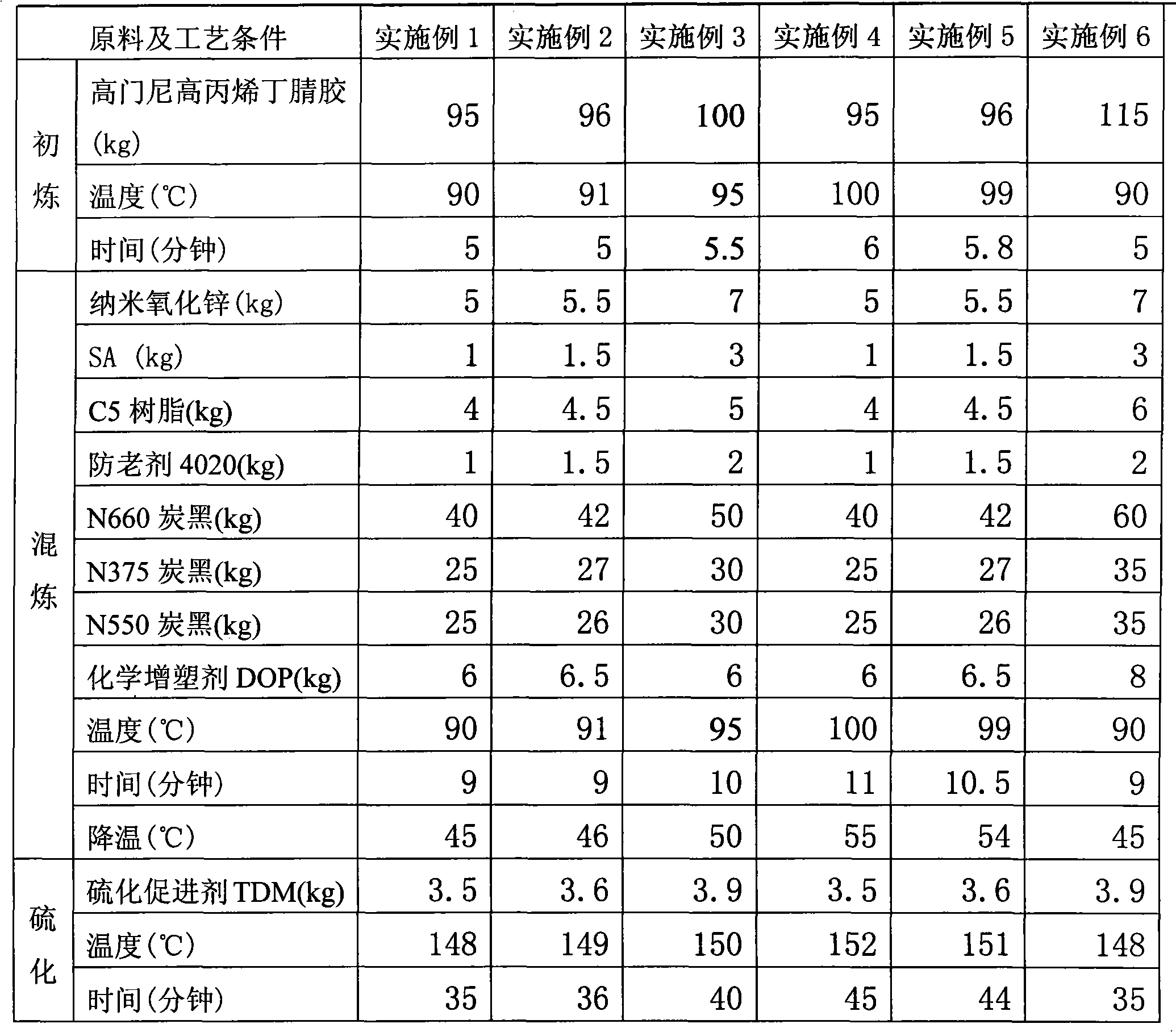

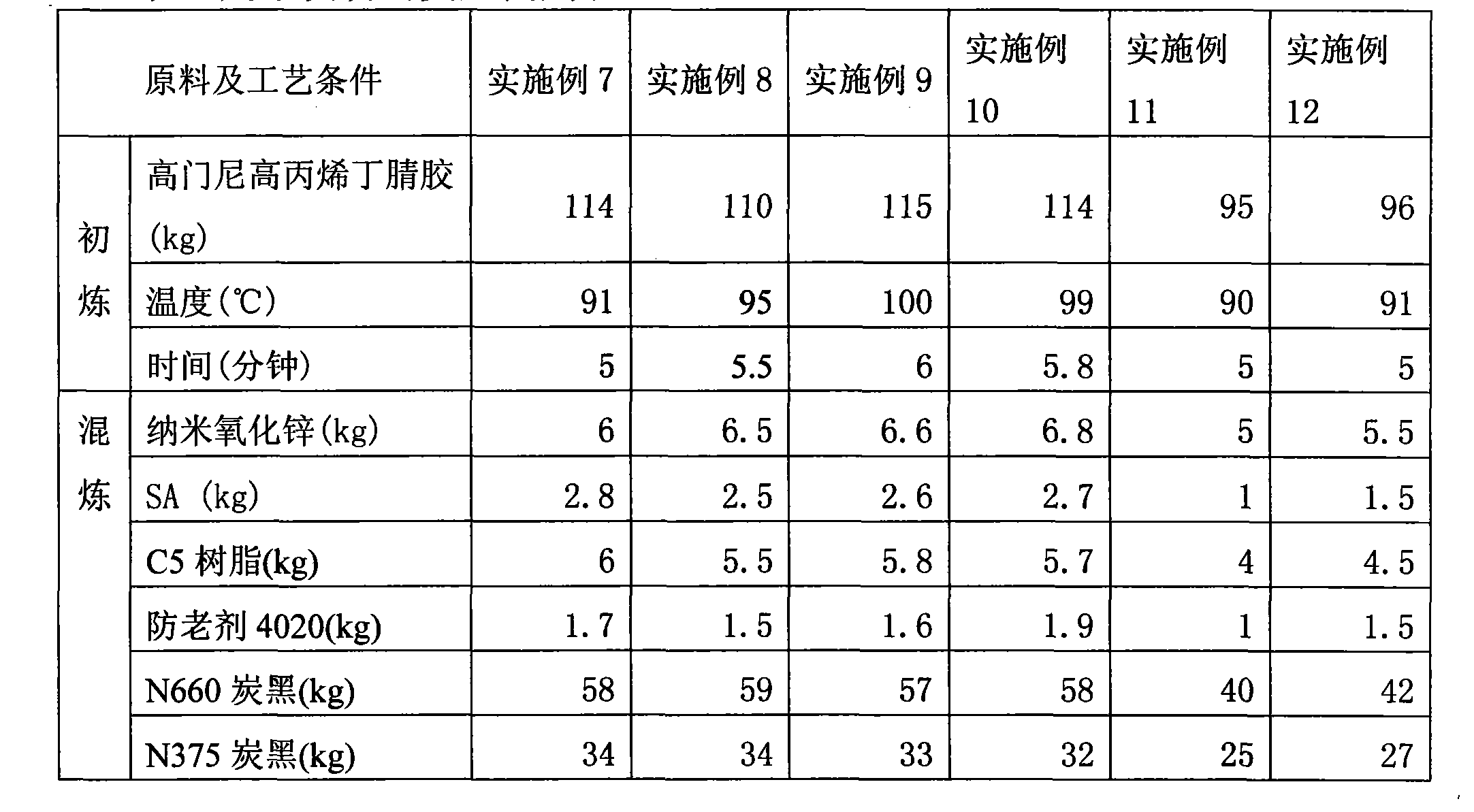

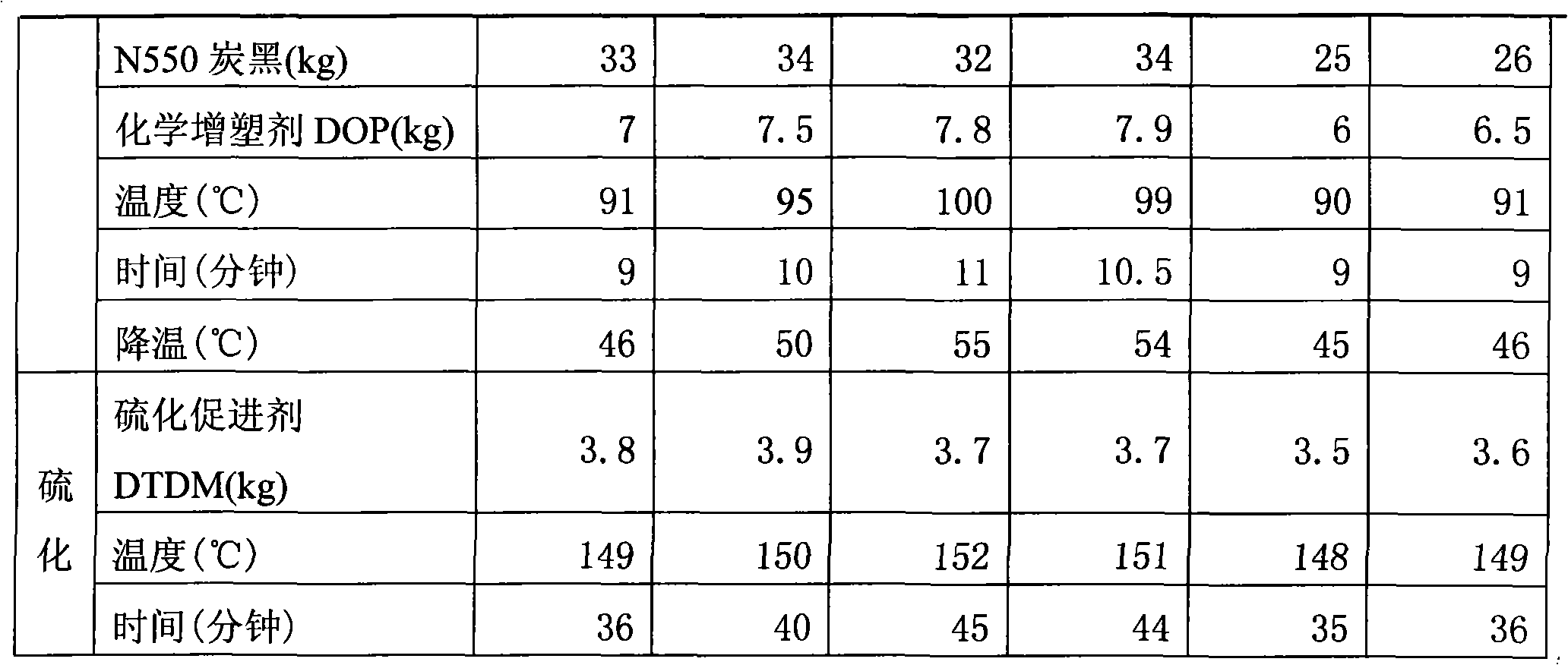

[0015] Embodiment: Take the following raw materials by weight: 95-115 parts of nitrile rubber, 6-10 parts of active agent, 4-6 parts of resin, 1-2 parts of anti-aging agent, 40-60 parts of highly dispersed low-structure carbon black, 6-8 parts of chemical plasticizer, 3.5-3.9 parts of vulcanization accelerator.

[0016] Prepare as follows:

[0017] ①Initial refining: put nitrile rubber in a closed rubber refining machine at 90°C-100°C for 5-6 minutes;

[0018] ②Mixing: Add active agent, resin, anti-aging agent, highly dispersed low-structure carbon black and chemical plasticizer and mix for 9-11 minutes at 100°C-110°C, discharge the mixed rubber and place it on the open mill through roller 2- 3 times, cool down to 45°C-55°C;

[0019] ③Vulcanization: add vulcanizing agent, three packs, two rolls and one thin pass in the open-type rubber refining machine, the roll distance is 0.4mm-0.6mm, and the sheet is released, parked and pressed out, and vulcanized at 148°C-152°C for 35-4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com