Antibacterial double-layer polyethylene tube

A polyethylene pipe, double-layer technology, applied in the field of double-layer polyethylene water pipes, can solve the problems of no antibacterial long-term effect, complex process, easy loss of antibacterial agents, etc., to achieve safe and reliable use, strong adaptability to the environment, The effect of low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

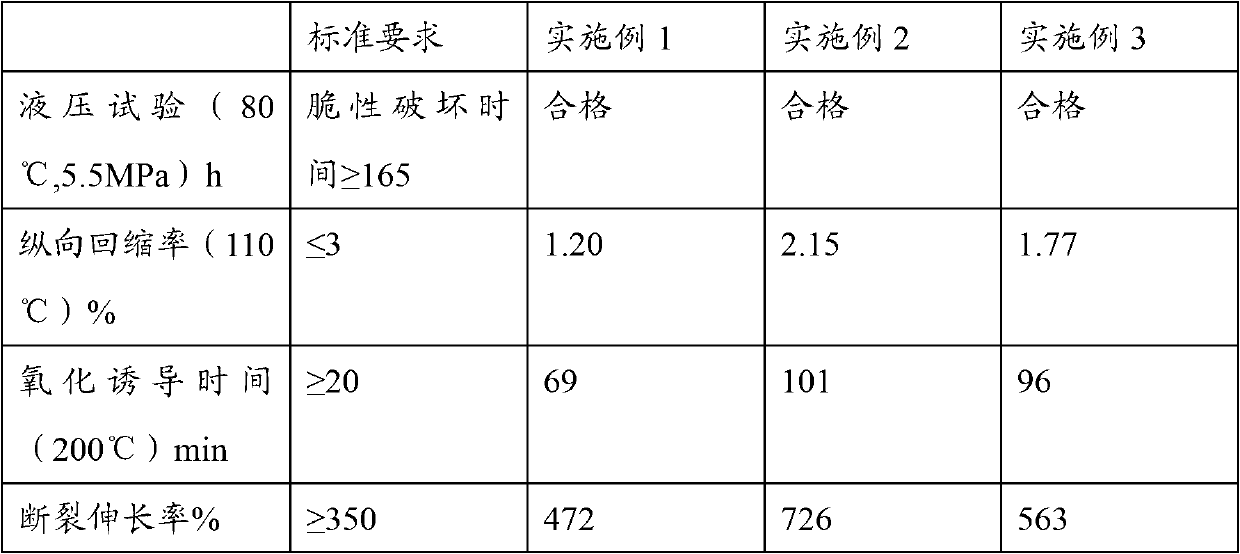

Examples

Embodiment 1

[0031] First prepare the carbon nanotubes modified by nano silver particles according to the following steps:

[0032] Dissolve 0.1mol of silver nitrate in 250mL of water, add 250ml of ammonia water with a mass concentration of 10%, and stir for 30 minutes after the addition is completed to form an alkaline aqueous solution of silver ammonia complex; add 10g of carbon nanotubes to 100ml with a mass concentration of 25 % hydrogen peroxide, mixed evenly and left for 10 minutes, then added to the alkaline aqueous solution of silver-ammonia complex prepared in step 1) to carry out the reduction reaction. After the end, the precipitate was separated and 200ml of methanol was added, washed several times, and the obtained brown-black solid That is nano-silver particles modified carbon nanotubes.

[0033]Choose MI at 10-12g / 10min; density 0.915g / cm 3 LDPE resin; the selected density is 0.963g / cm 3 , HDPE resin with a melt index of 12g / 10min.

[0034] In addition, the material ratio...

Embodiment 2

[0039] First prepare the carbon nanotubes modified by nano silver particles according to the following steps:

[0040] Dissolve 0.2mol of silver nitrate in 250mL of water, add dropwise 100ml of ammonia water with a mass concentration of 10%, and stir for 30 minutes after the addition is completed to form a silver-ammonia complex alkaline aqueous solution; add 50g of carbon nanotubes to 450ml with a mass concentration of 25 % hydrogen peroxide, mix well and place it for 30 minutes, add it to the alkaline aqueous solution of silver ammonia complex prepared in step 1) to carry out the reduction reaction, separate the precipitate after the end and add 300ml methanol, wash it three times, and the obtained brown-black solid is Modified carbon nanotubes for nano silver particles.

[0041] Choose MI at 2g / 10min; density 0.921g / cm 3 LDPE resin; the selected density is 0.967g / cm 3 , HDPE resin with a melt index of 32g / 10min.

[0042] In addition, the material ratio of the inner layer...

Embodiment 3

[0047] First prepare the carbon nanotubes modified by nano silver particles according to the following steps:

[0048] Dissolve 0.1mol of silver nitrate in 250mL of water, add 100ml of ammonia water with a mass concentration of 5% dropwise, and stir for 60 minutes after the addition is completed to form a silver-ammonia complex alkaline aqueous solution; add 2g of carbon nanotubes to 100ml with a mass concentration of 25 % hydrogen peroxide, mix well and place it for 60 minutes, add it to the alkaline aqueous solution of silver-ammonia complex prepared in step 1), and carry out the reduction reaction. After the end, separate the precipitate and add 200ml petroleum ether, wash it five times, and the obtained brown-black The solid is nano-silver particle-modified carbon nanotube.

[0049] Choose MI at 1g / 10min; density 0.913g / cm 3 LDPE resin; the selected density is 0.966g / cm 3 , HDPE resin with a melt index of 6g / 10min.

[0050] In addition, the material ratio of the inner l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com