Al-Mg-Mn alloy plate archaizing roof tile and manufacturing method thereof

A technology of aluminum-magnesium-manganese alloy and production method, which is applied to roofs, roofs, and roof coverings using tiles/slate tiles, and can solve the problems of poor oxidation resistance of copper antique roof tiles, difficult manufacturing process, and poor durability of cement tiles And other problems, to achieve realistic production effect, good antique effect, convenient construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

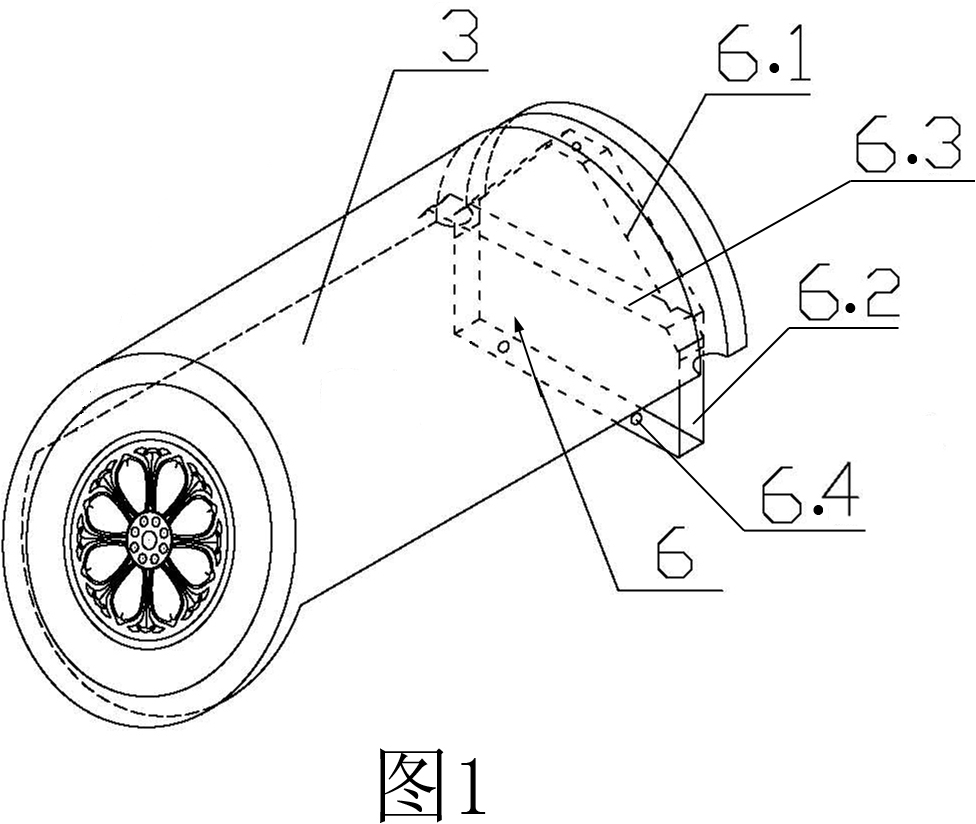

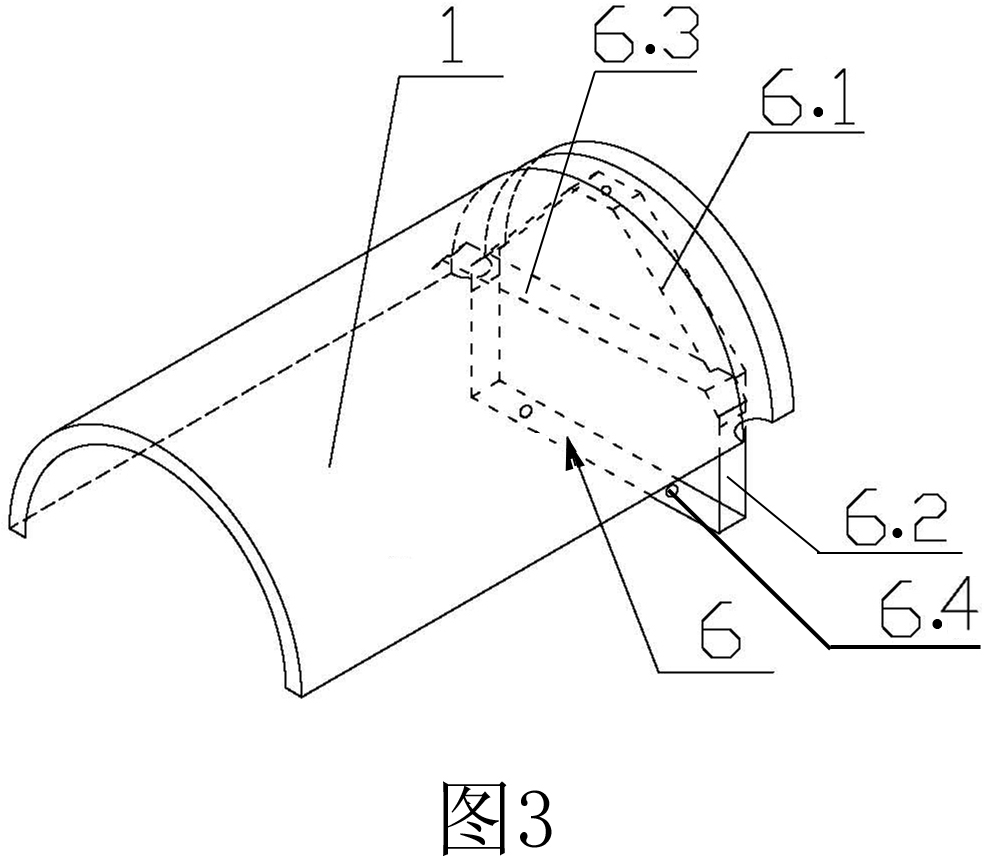

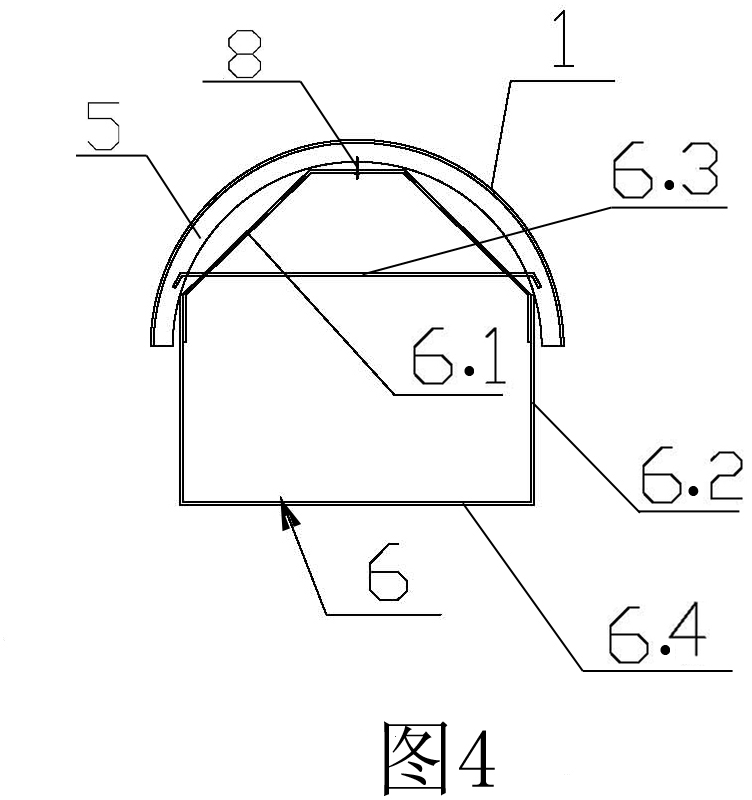

[0044] Embodiment one sees Figure 1 to Figure 13 As shown, an aluminum-magnesium-manganese alloy plate antique roof tile, including a cylindrical tile 1 and a flat tile 2, is characterized in that: the cylindrical tile 1 and the flat tile 2 are stamped from an aluminum-magnesium-manganese alloy plate; the flat tile 2 is Curved sheet shape, on both sides of the tile body 2.1, there is an L-shaped bead 2.2 extending directly upward, and its edge has a lower bending edge 2.6 with a width equal to the thickness of the tile. The lower surface of the tile body 2.1 is welded with reinforcing ribs 7 and The length is the same as the width of the tile body; the tube tile 1 is longitudinally cut into a half-cylindrical shape, and the tube edge has a curved edge 5 whose width is the thickness of the tile, and the inner wall of the tube is connected with a support frame 6 through a fastener 8. The side is supported on the horizontal limb 2.3 of the L-shaped edge of the plate tile 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com