Cord core drilling tool for tunnel subhorizontal hole

A core drilling tool and horizontal hole technology, which is applied in the direction of extracting undisturbed cores, earthwork drilling, etc. Work efficiency, effectiveness in solving applicability issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] The present invention relates to a cable core drilling tool for near-horizontal holes in tunnels, which is a technical improvement on the basis of the existing cable core drilling tools for near-vertical holes.

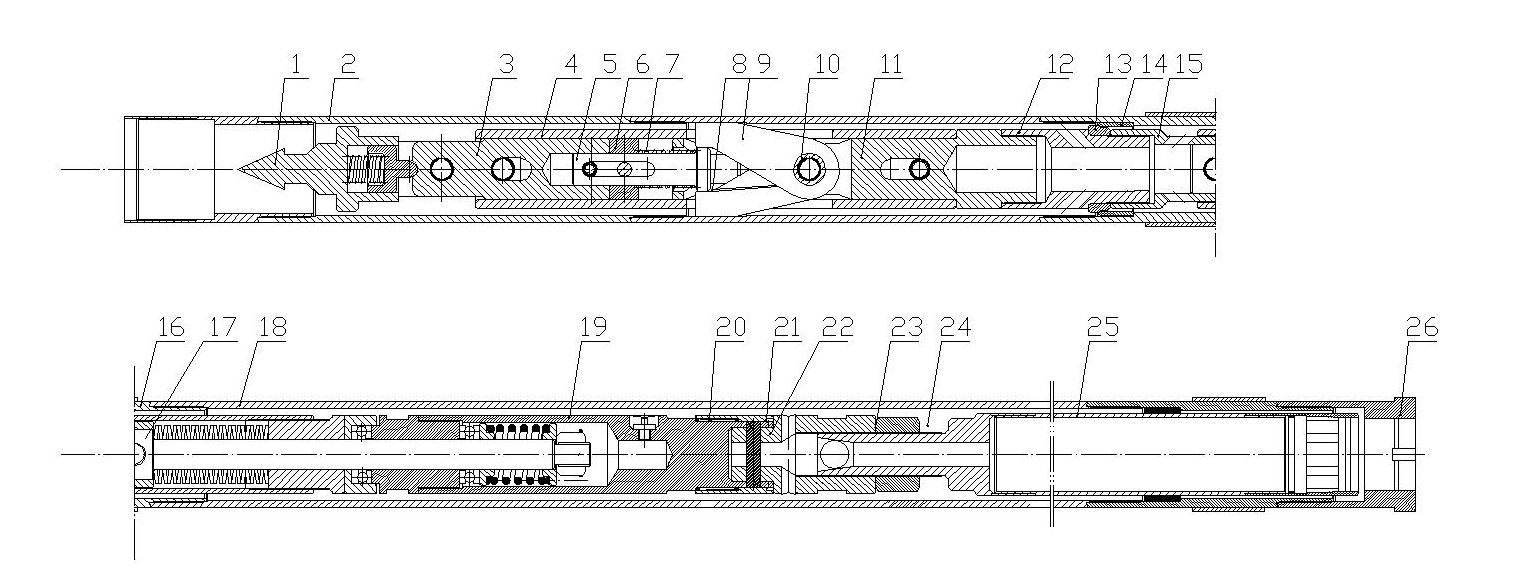

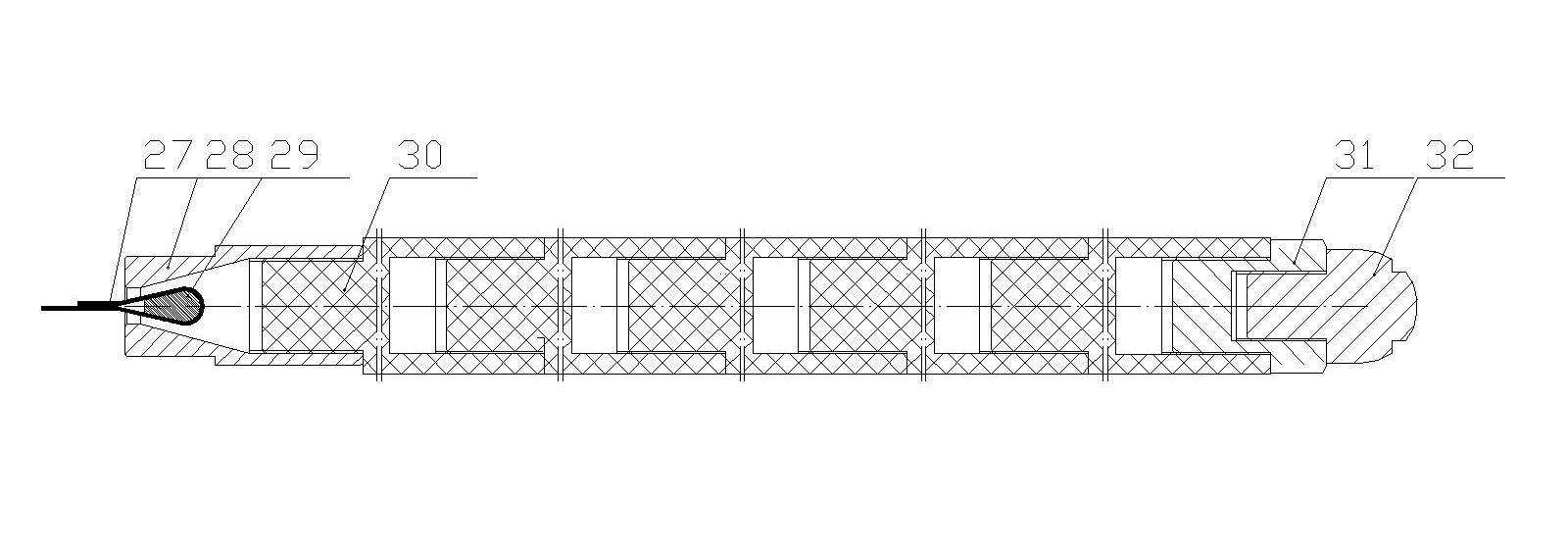

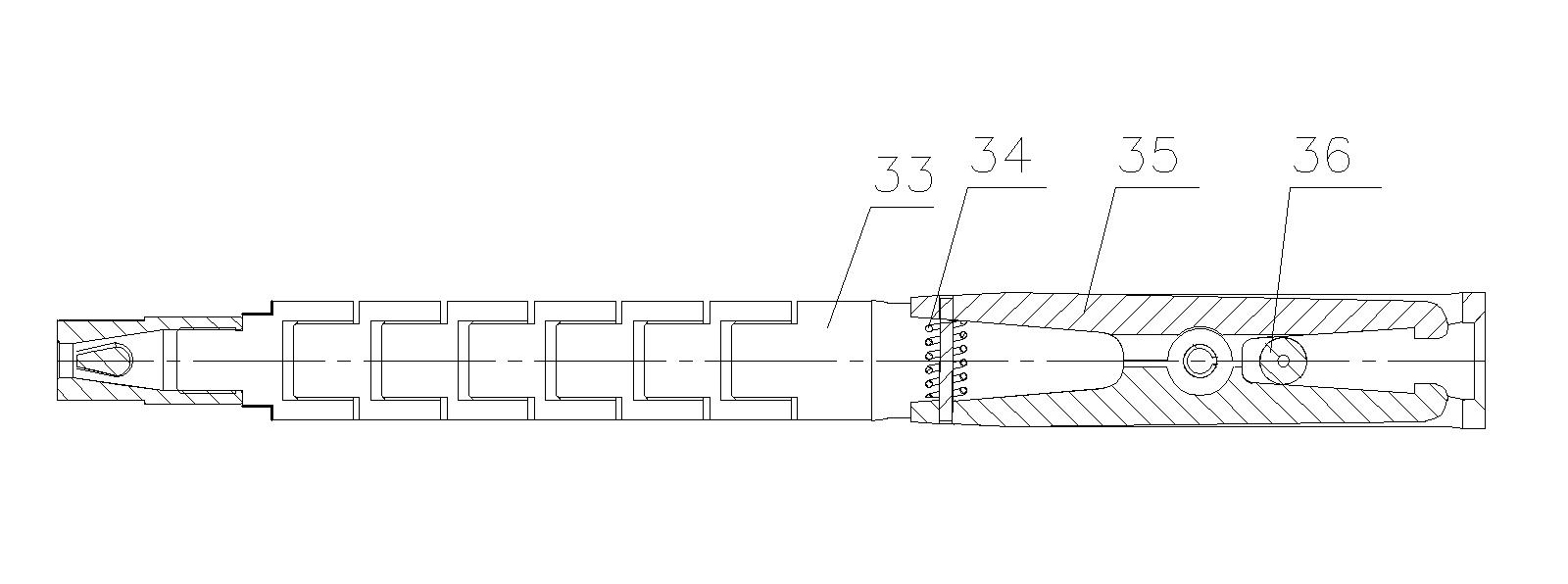

[0022] First of all, the composite positioning mechanism designed in the inner tube assembly of the present invention is the bullet clip composed of the mandrel 5, the cushion block 6, the spring 7, the tension spring 8, the clip 9, the pin sleeve 10 and the clip seat 11. Positioning mechanism and mandrel positioning mechanism. Tension spring 8 and bullet clip 9 are connected by pin sleeve 10, and the total thickness of bullet clip two wings is equal to the groove width of bullet clip seat 11, utilizes elastic cylindrical pin that tension spring 8 and bullet clip 9 are connected on the bullet clip seat 11. When the inner pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com