Semiconductive EVA plastic shielded flexible cable and manufacturing method thereof

A semi-conductive, flexible cable technology, used in cable/conductor manufacturing, insulated cables, flexible cables, etc., can solve a wide range of applications and other problems, achieve enhanced tensile capacity, good machinability, and tensile strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with example the present invention will be further described:

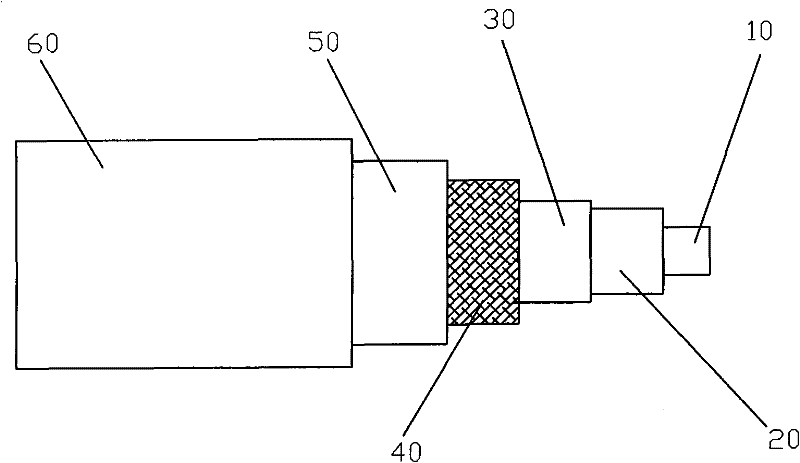

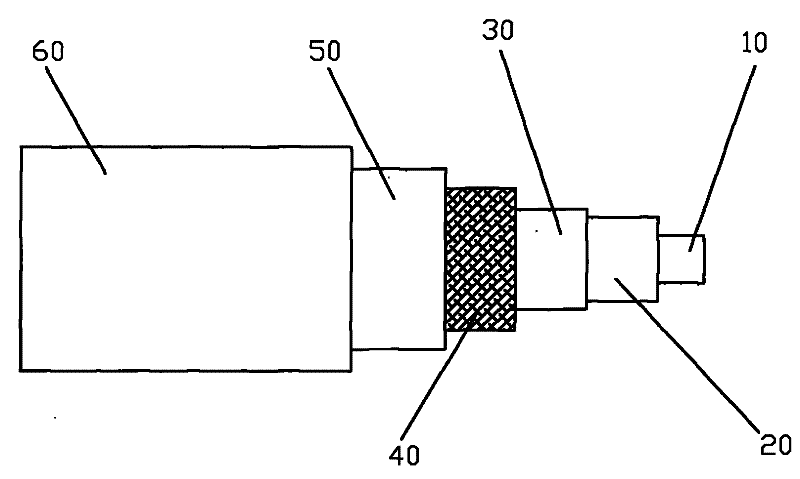

[0040] exist figure 1 Among them, a semi-conductive EVA plastic shielded flexible cable includes a copper core conductor 10, and the outer layer of the copper core conductor 10 is coated with a polyvinyl chloride insulating layer 20, an aluminum foil Mylar 30, a fiber braiding layer 40, and a semi-conductive EVA plastic shielding layer. 50 and the polyvinyl chloride outer sheath 60, these six parts are covered layer by layer from the inside to the outside. In practice, the copper core conductor is twisted with multiple annealed bare copper wires. The outer layer of the copper core conductor is covered with a polyvinyl chloride insulating layer to form a core wire. The core wire can be set to two cores or more than two cores to meet the needs of different purposes and occasions. The core wires need to be twisted when forming a cable.

[0041] In the present embodiment, semi-conductive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com