Microemulsion composition and preparation method thereof

A technology of composition and microemulsion, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., can solve the problems of micro-toxicity, and achieve the effects of small impact, transdermal penetration, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

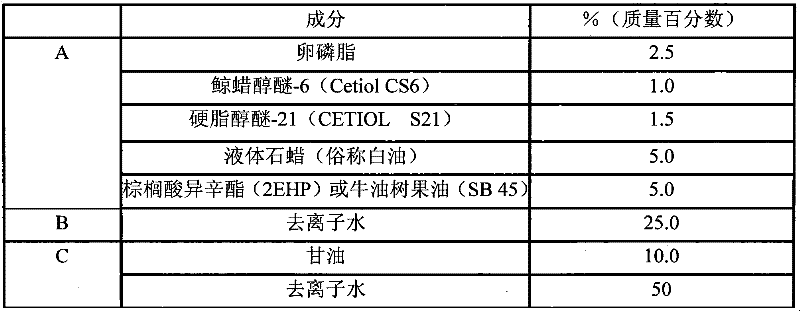

[0040] Weigh raw materials according to the table:

[0041]

[0042] Step 1, heat component A to 75°C and stir evenly; at the same time, heat component B to 75°C;

[0043] Step 2, under stirring, slowly drop component B into component A, and stop heating when obvious blue light is observed;

[0044] Step 3, cooling the solution in step 2 until the temperature drops to 35° C., adding component C and stirring evenly to obtain a microemulsion composition.

Embodiment 2

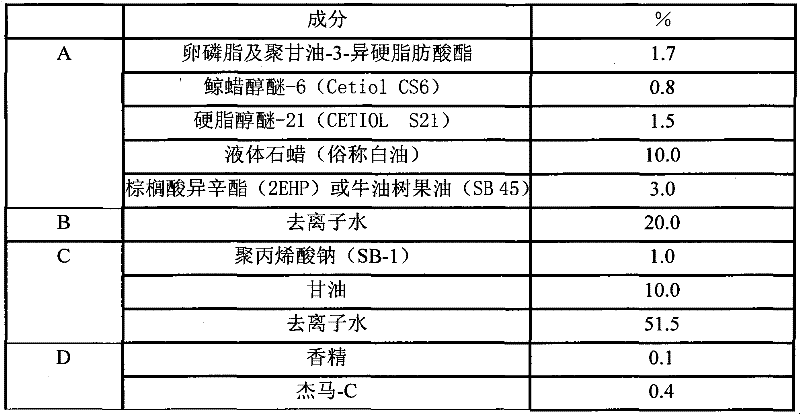

[0046] Weigh raw materials according to the table:

[0047]

[0048] Step 1, heat component A to 85°C and stir evenly; at the same time, heat component B to 85°C;

[0049] Step 2, under stirring, slowly drop component B into component A, and stop heating when obvious blue light is observed;

[0050] Step 3, cooling the solution in step 2 until the temperature drops to 40°C, adding component C, stirring evenly to obtain a microemulsion composition;

[0051] Step 4, further cooling the solution in step 3 to room temperature, adding component D, and stirring evenly to obtain a microemulsion composition.

Embodiment 3

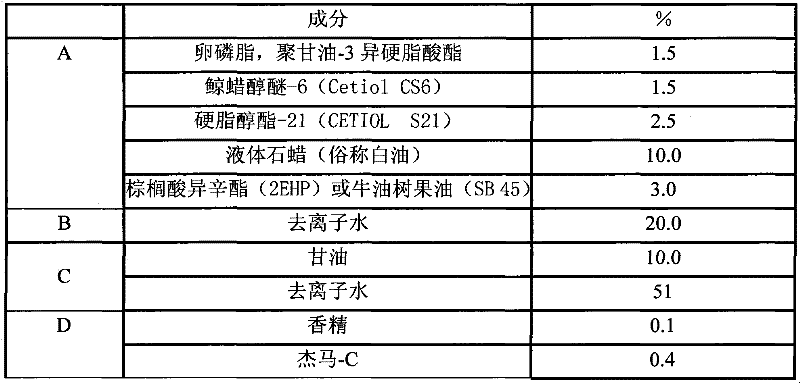

[0053] Weigh raw materials according to the table:

[0054]

[0055] Step 1, heat component A to 80°C and stir evenly; at the same time, heat component B to 80°C;

[0056] Step 2, under stirring, slowly drop component B into component A, and stop heating when obvious blue light is observed;

[0057] Step 3, cooling the solution in step 2 until the temperature drops to 45°C, adding component C, stirring evenly to obtain a microemulsion composition;

[0058] Step 4, further cooling the solution in step 3 to room temperature, adding component D, and stirring evenly to obtain a microemulsion composition.

[0059]The present invention adopts nonionic emulsifier, selects suitable grease, and the microemulsion composition droplet that forms is far smaller than emulsion droplet, and disperses more evenly, and the impact on external environment is little, more stable, therefore, can be used as solvent, has It is conducive to transdermal penetration and promotes the exertion of fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com