Water jacket for inner heat-storing coal-gas furnace

A technology of gas generator and water jacket, which is used in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of affecting the application performance and service life, reducing the steam decomposition rate, and the heat loss of the water jacket, etc., so as to improve the steam decomposition rate, improve application performance, reduce the effect of wall hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

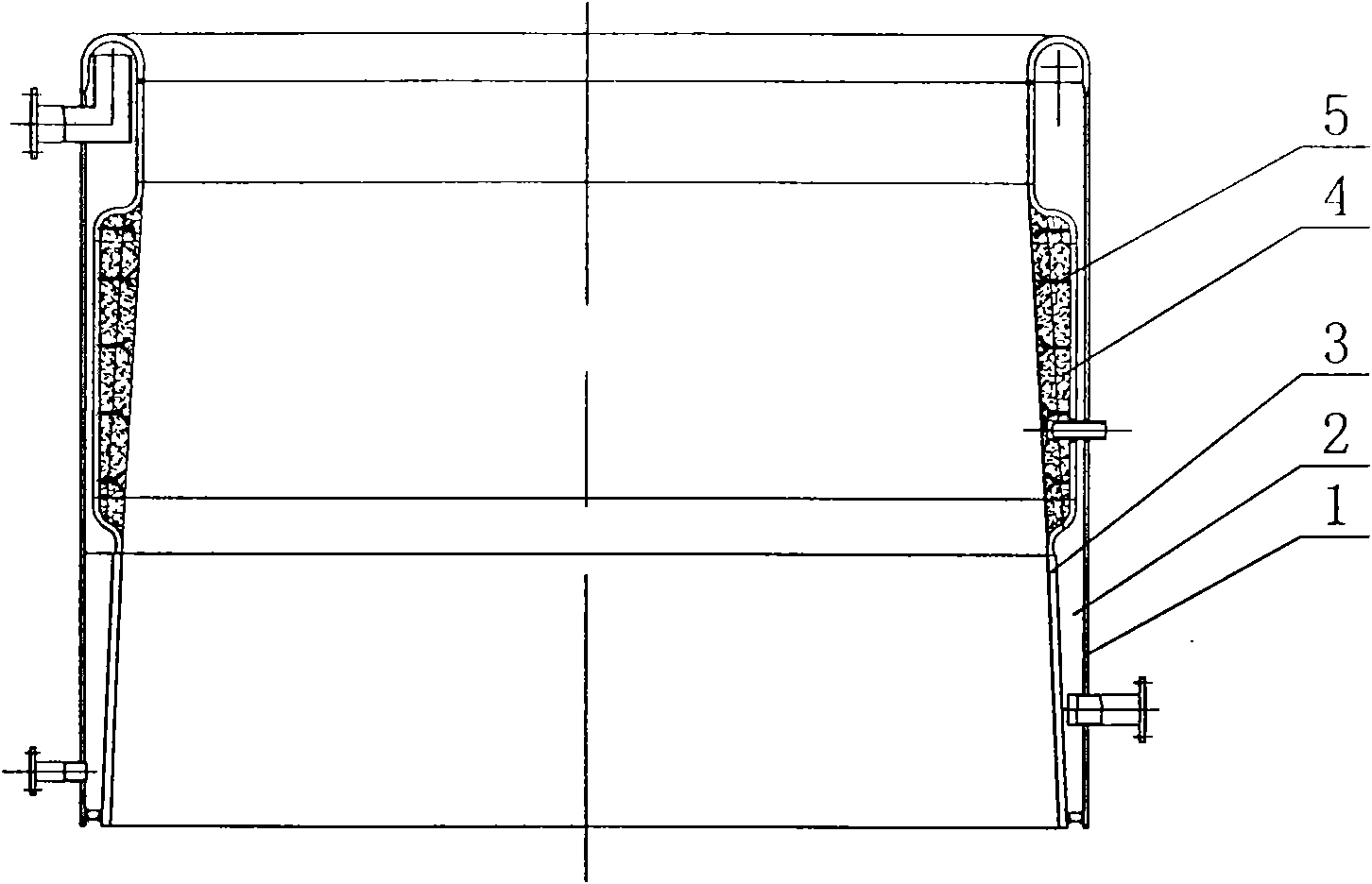

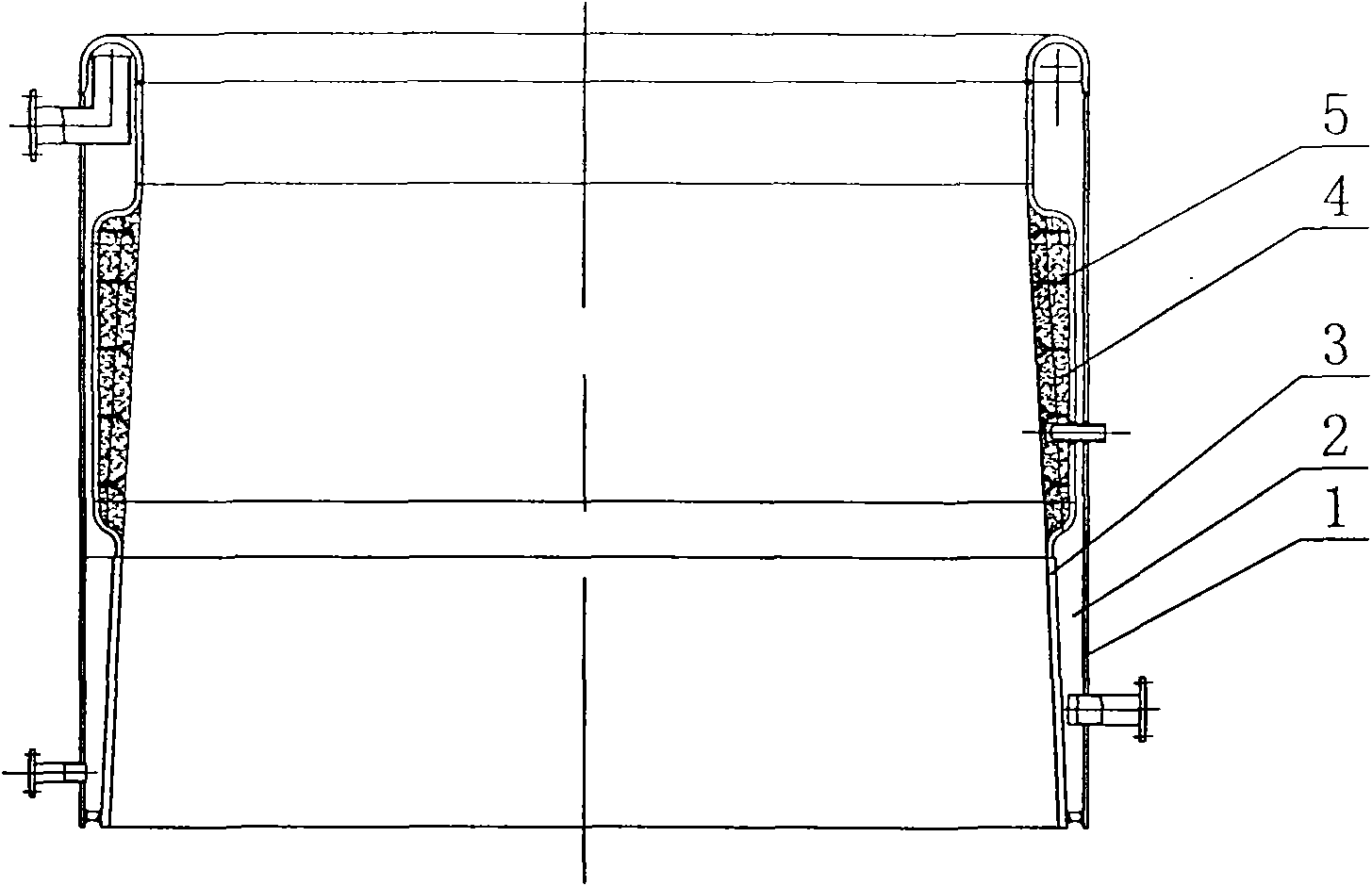

[0010] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

[0011] As shown in the figure, in the water jacket of the internal heat storage gas generator according to the present invention, the water jacket cavity 2 is between the inner and outer walls 3 and 1 of the water jacket, and the inner wall of the water jacket corresponding to the furnace area is covered with refractory heat preservation Layer 4. The refractory insulation layer 4 is an overall structure formed by casting refractory insulation castables, in which a Y-shaped anchor piece 5 is embedded, and the inner end of the anchor piece 5 is fixed on the inner wall 3 of the water jacket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com