Silencing exhaust device for high-power engine

An exhaust device and engine technology, applied in the direction of muffler, exhaust device, engine components, etc., can solve the problems of substandard noise reduction, engine power loss, high temperature of muffler cylinder, etc., to reduce surface temperature and regenerate noise Low, small pressure loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

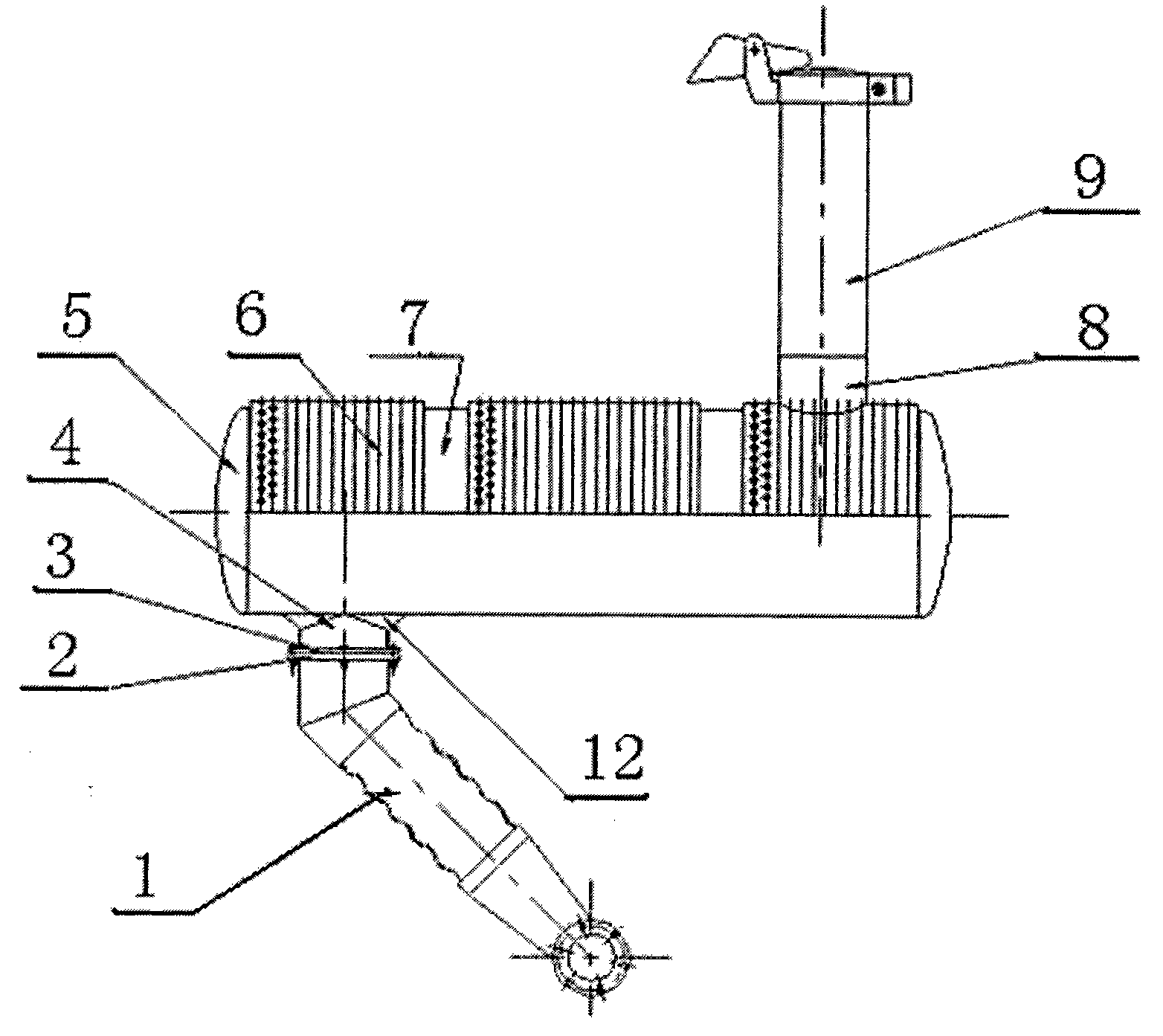

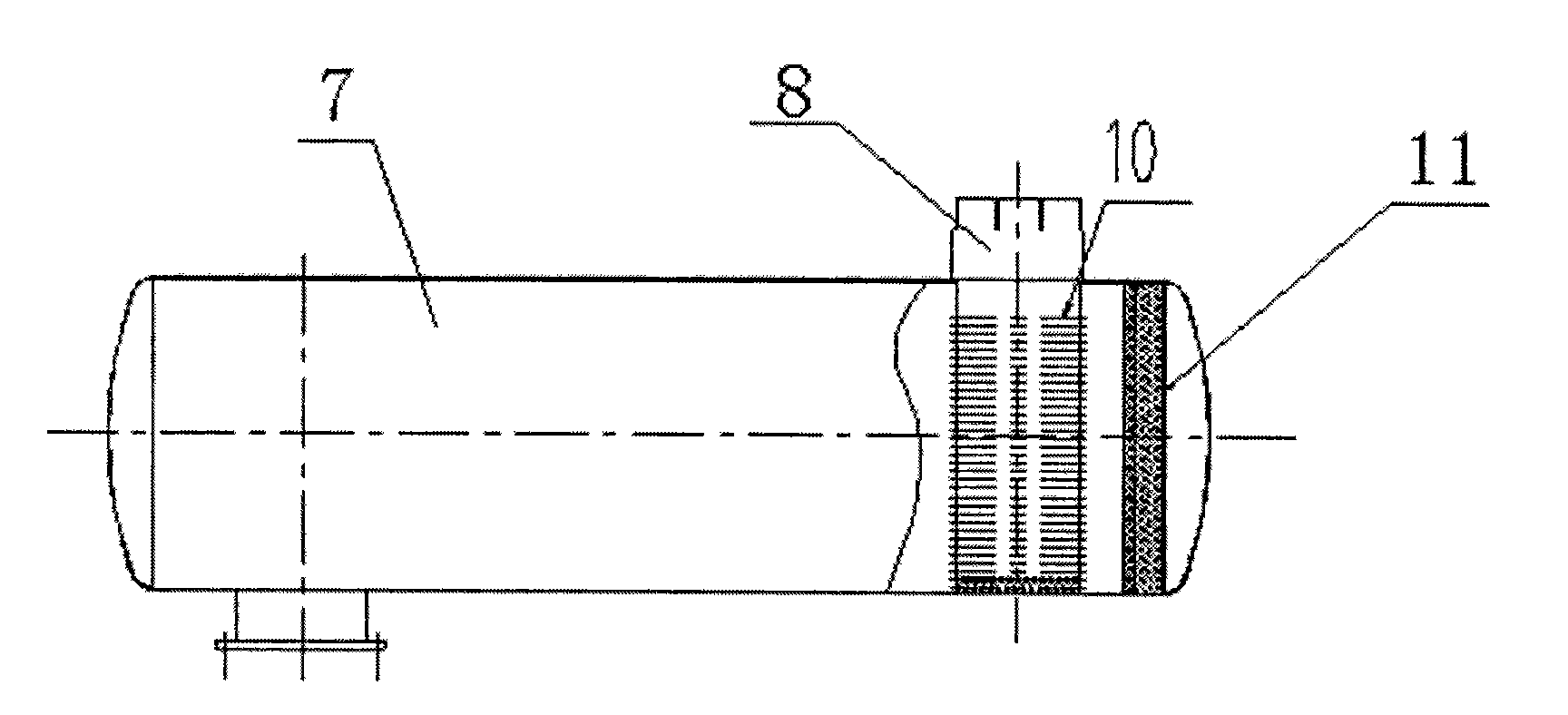

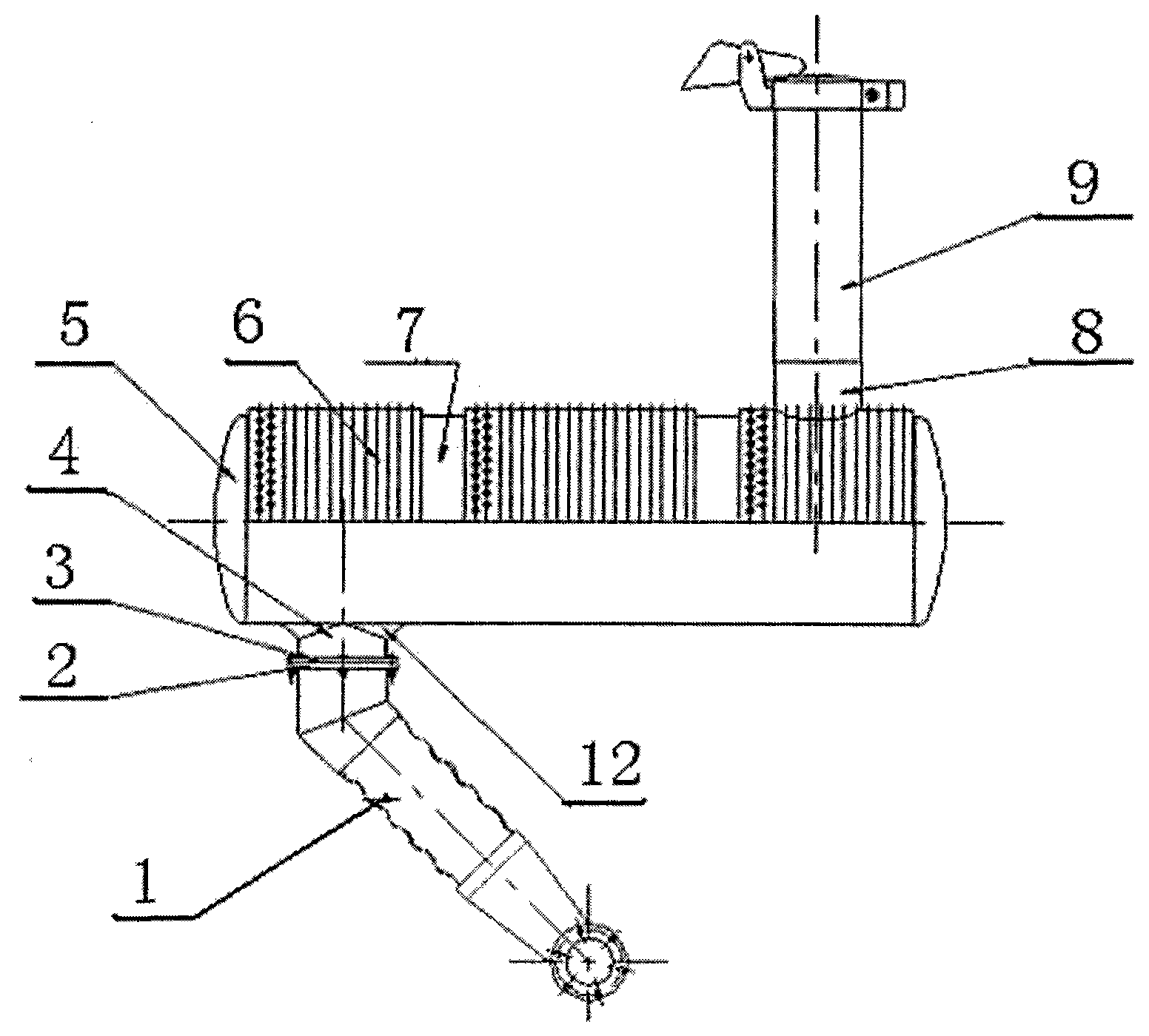

[0012] Depend on figure 1 It is known that it is a structural schematic diagram of the present invention, a noise-absorbing exhaust device for a high-power engine, including an air intake connecting pipe 1, an air inlet 4, a cylinder 7, an air outlet 8 and an exhaust pipe 9, and the cylinder 7 is the two ends The cylindrical shape of the round end cover 5 is arranged, the intake pipe is connected as a whole with the device through the bolt connection of the takeover flange I and the takeover flange II, and the exhaust pipe 9 is connected with the device by a hoop. Ingot sheet 12 is welded on air inlet 4, and ingot sheet 12 can strengthen the strength of air inlet 4 and cylinder body 7 welding place, and end cap 5 is welded on the two ends of cylinder body 7. The exhaust pipe 9 is arranged on the upper part of the cylinder 7 through the air outlet 8, and the outer wall of the cylinder 7 is provided with a heat insulating plate 6, which is covered with small holes, and the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com