Engineering machinery engine energy-saving cooling fan

A technology of construction machinery and cooling fan, applied in the direction of engine cooling, machine/engine, engine components, etc., can solve the problems of large intermediate energy transfer loss, high price, shorten the life of the engine and radiator, etc., to improve the service life, The effect of high work efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

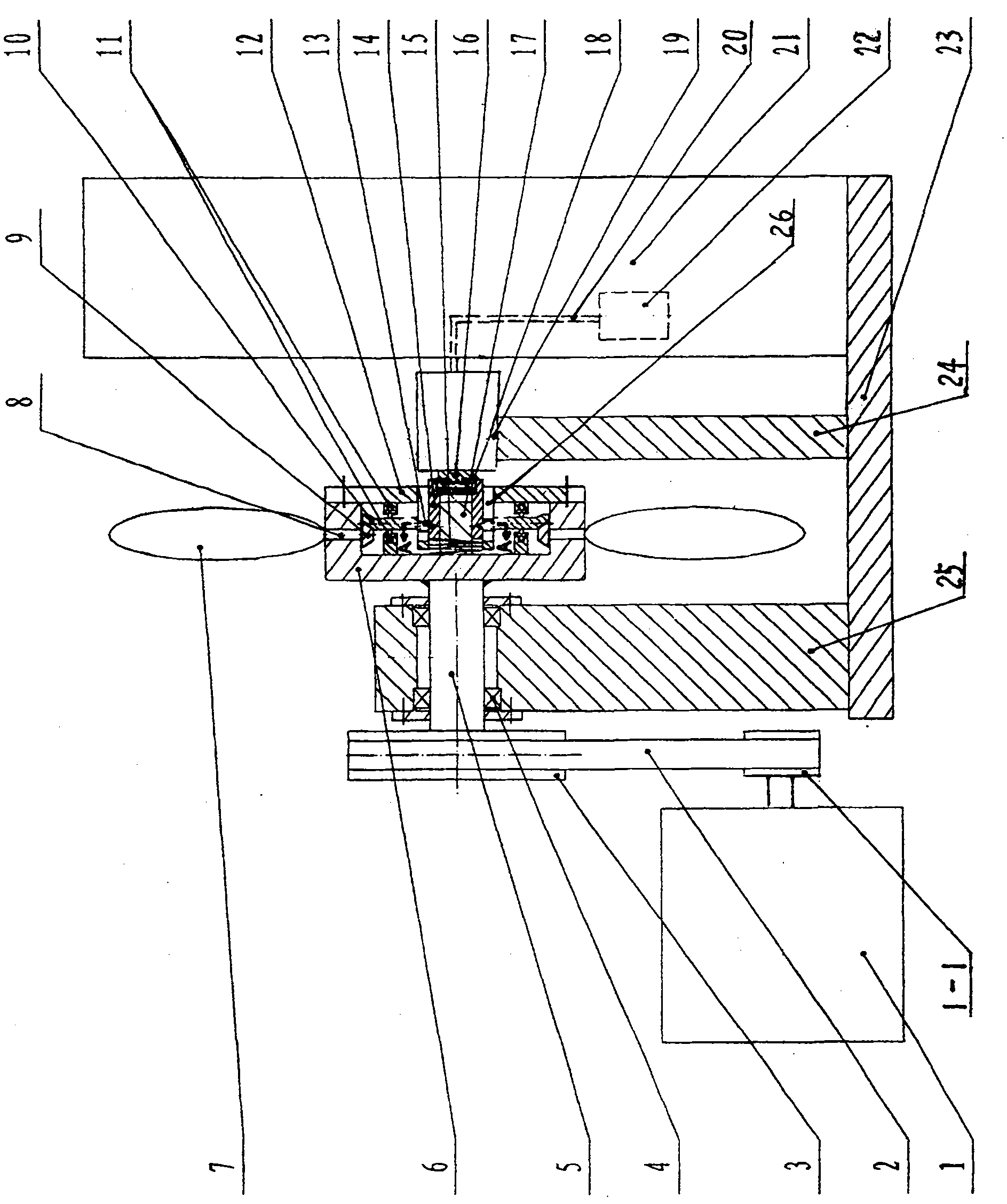

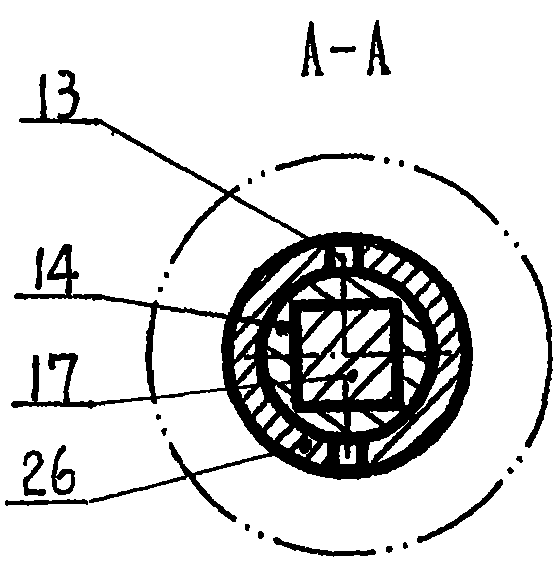

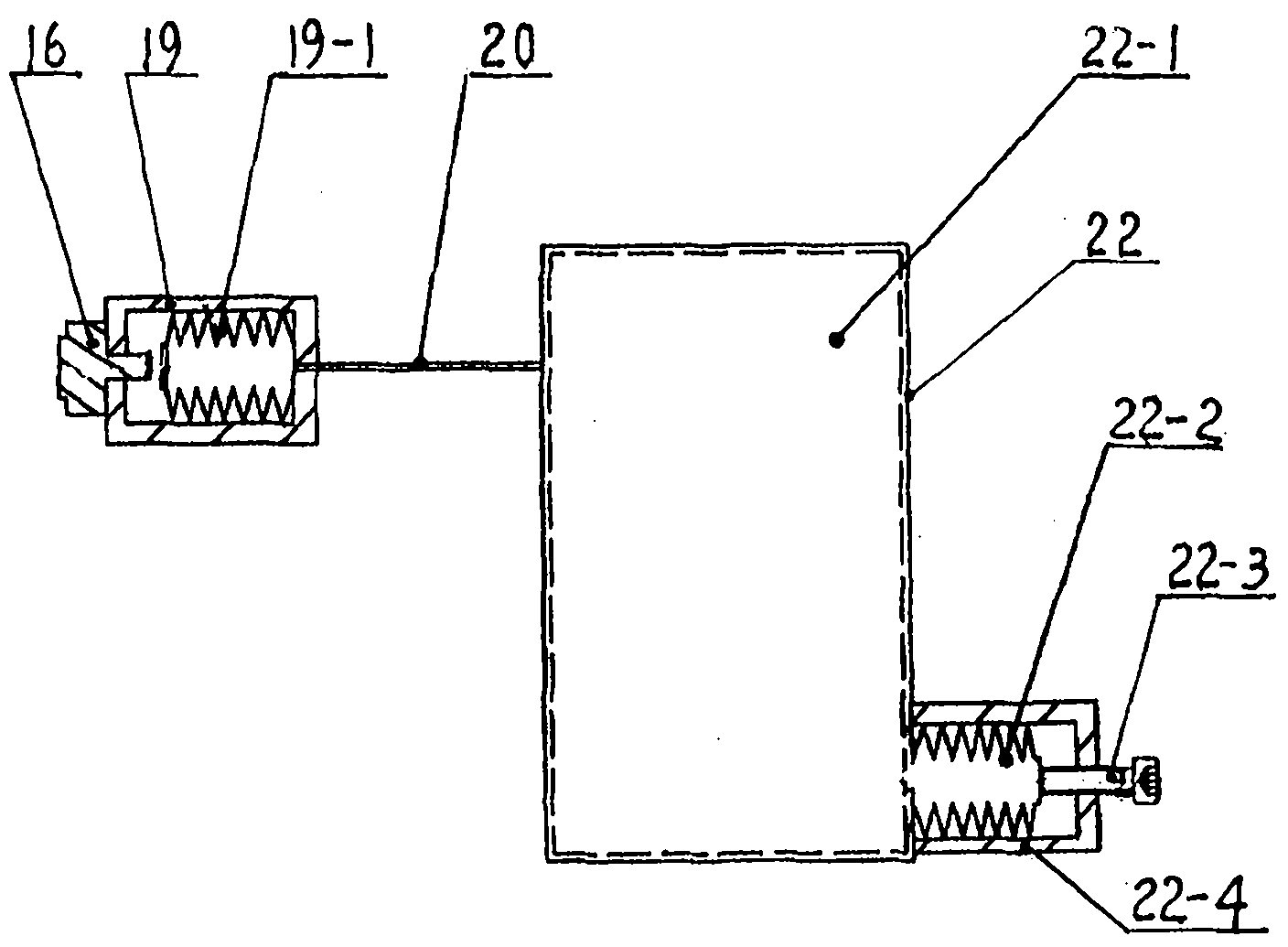

[0011] Examples, see attached figure 1 , 2 3. Fixed shaft support 25 on the left end of the base 23 of the energy-saving cooling fan of the engineering machinery engine, fixed temperature drive part support 24 in the middle, and fixed radiator 21 on the right end. Fixed engine 1 on the left side of base 23, engine pulley 1-1 is adorned in the center of the right side of engine 1, and engine pulley 1-1 connects pulley 3 with belt 2 transmission, and pulley 3 is contained on the left end of pulley shaft 5, and pulley shaft 5 is fixed on the top of the shaft support 25 with the bearing 4. A wheel hub 6 is welded and fixed on the right end of the shaft bracket 25, and several blade shafts 8 are installed radially symmetrically on the circumferential wall of the wheel hub 6, and several blades 7 are mounted symmetrically on the outer wall of the wheel hub 6 on the blade shaft 8, and the blade shafts 8 Several small bevel gears 9 are installed symmetrically with the blades 7 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com