Uniset for tracking and monitoring tail gas temperature verification thermal efficiency of steam-jetting type engine

A technology of tracking monitoring and combined devices, applied in the direction of internal combustion engine testing, etc., can solve problems such as potential safety hazards, promotion and application of technical solutions and technical means, teaching aids, pollution, etc., and achieve the effect of relaxing time and conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

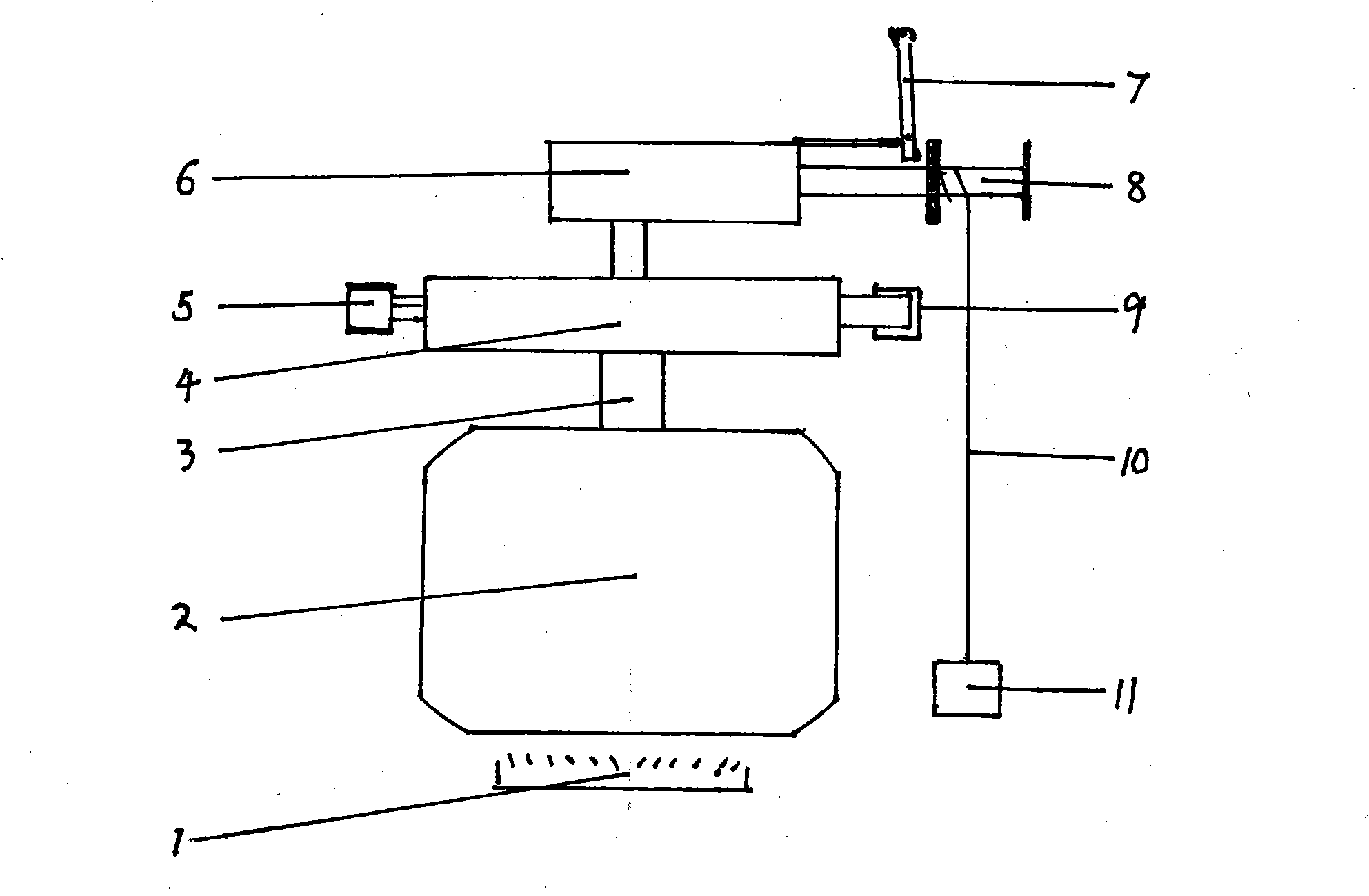

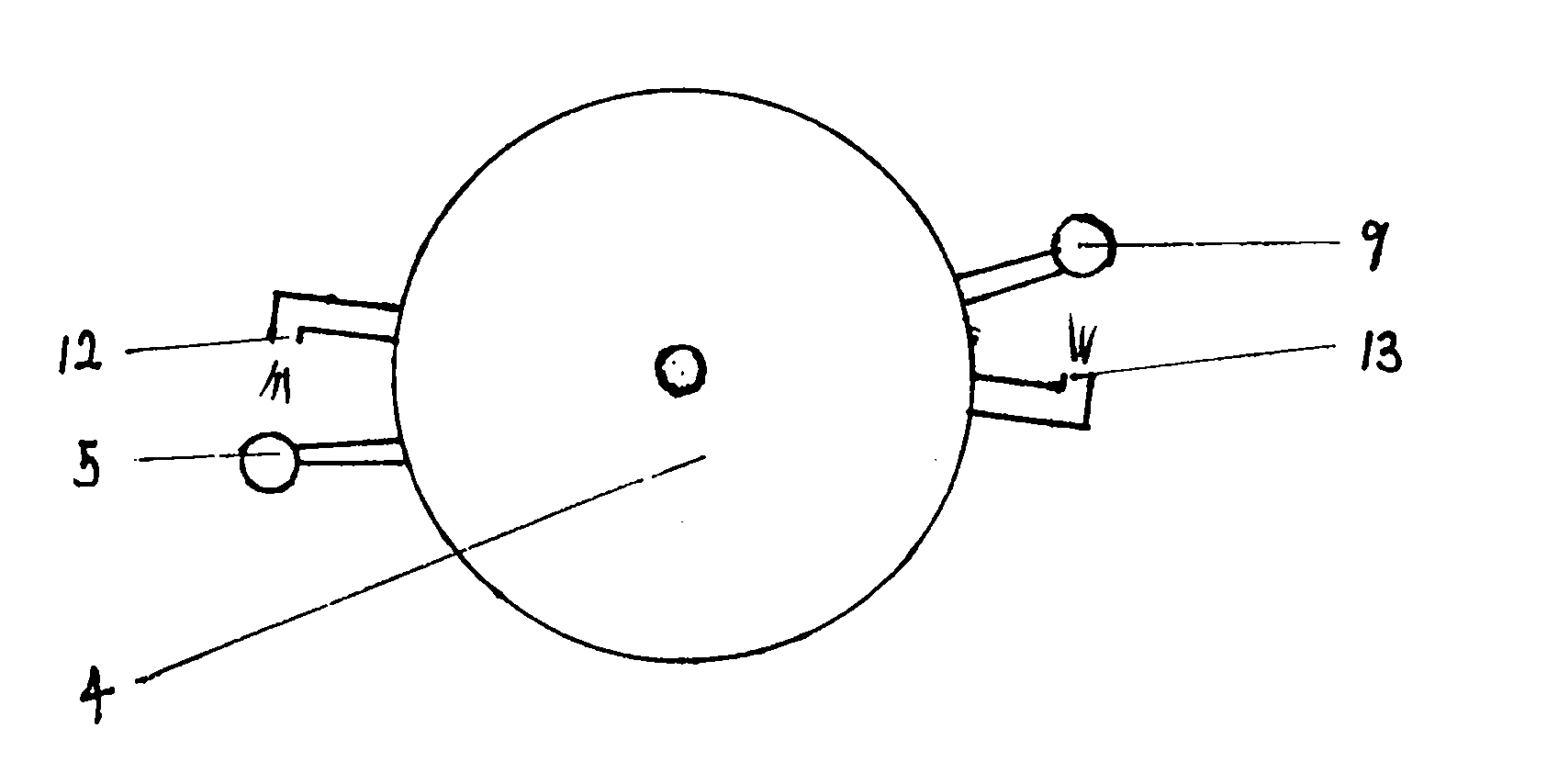

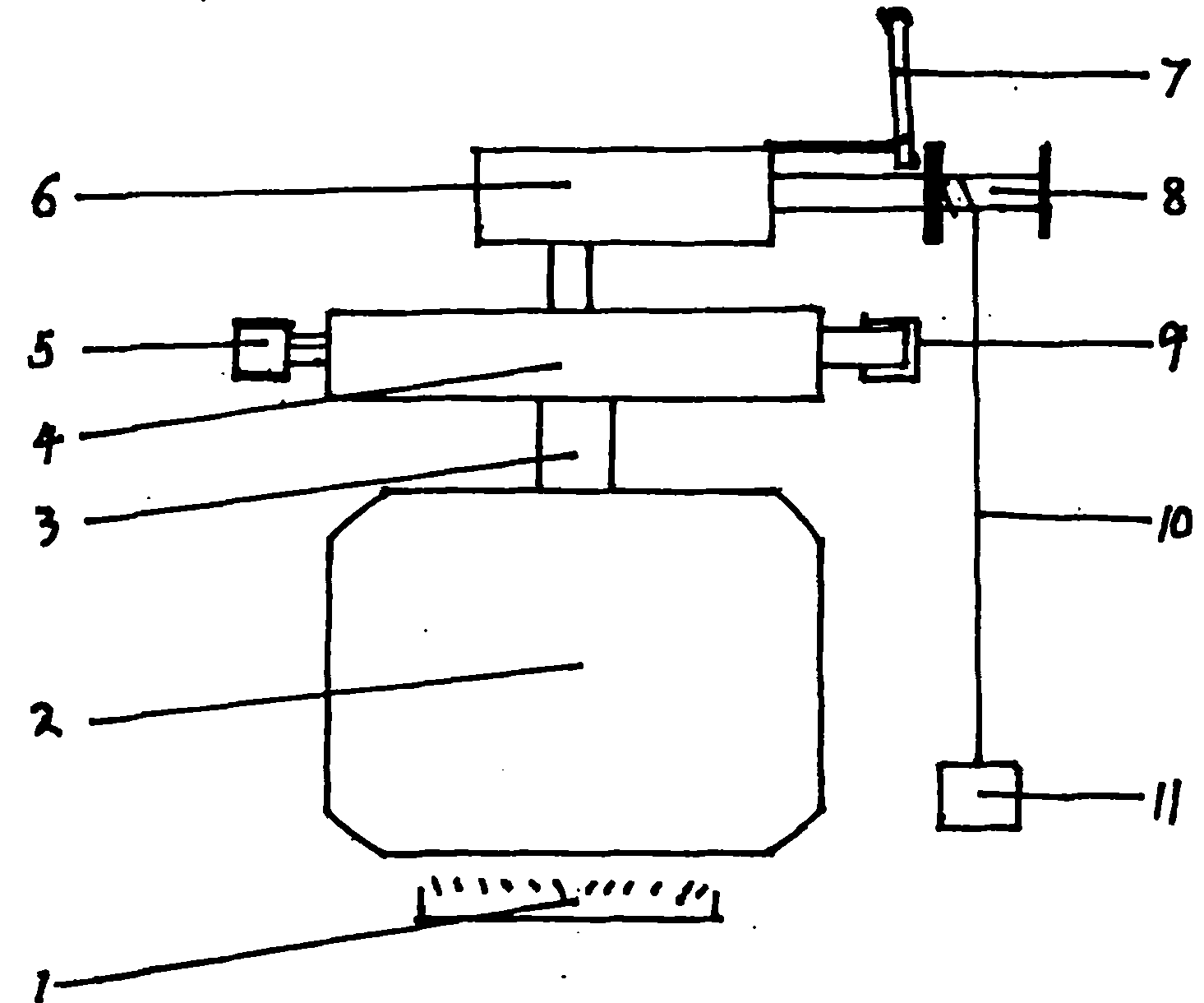

[0021] combine figure 1 figure 2 , heated by a gas furnace, so that the water in the pressure cooker 2 is heated and turned into high-pressure and high-temperature steam, which enters the inner cavity of the rotor 4 through the hollow shaft 3, and finally sprays out at two nozzles 12 and 13 at high speed, and the recoil force causes the rotor 4 to generate steam. Torque thus rotates at a high speed, drives the winch 6, and lifts the heavy object 11 by winding the traction rope 10 by the reel 8, and this moment is the working state. When the brake handle 7 is pushed to brake the reel 8, the rotor 4 is forced to stop rotating through linkage, and it is in a non-working state at this moment. The hollow shaft 3 plays a role of supporting and guiding the rotor 4, and through tight fit, the rotor 4 can be continuously sprayed out through the nozzles 12 and 13 without leakage no matter whether the rotor 4 rotates at high speed or stops. Since the cooperation of the two is an obvio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com