Exhaust gas recirculation cooling element for an internal combustion engine

A technology of exhaust gas recirculation and cooler, applied in the direction of internal combustion piston engine, combustion engine, heat exchanger, etc., can solve the problems of insufficient efficiency and achieve the effects of compact structure, extended inspection and maintenance intervals, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

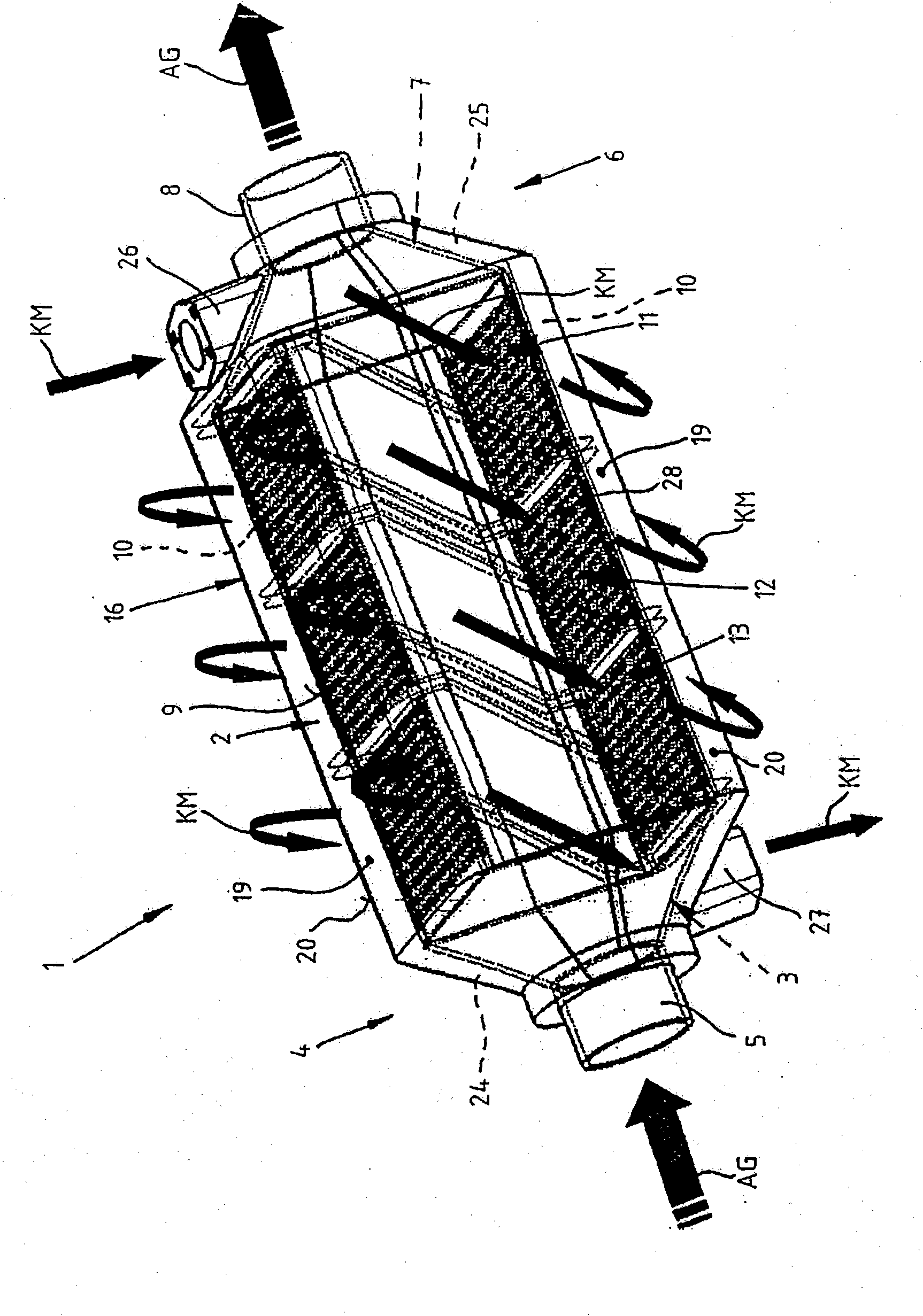

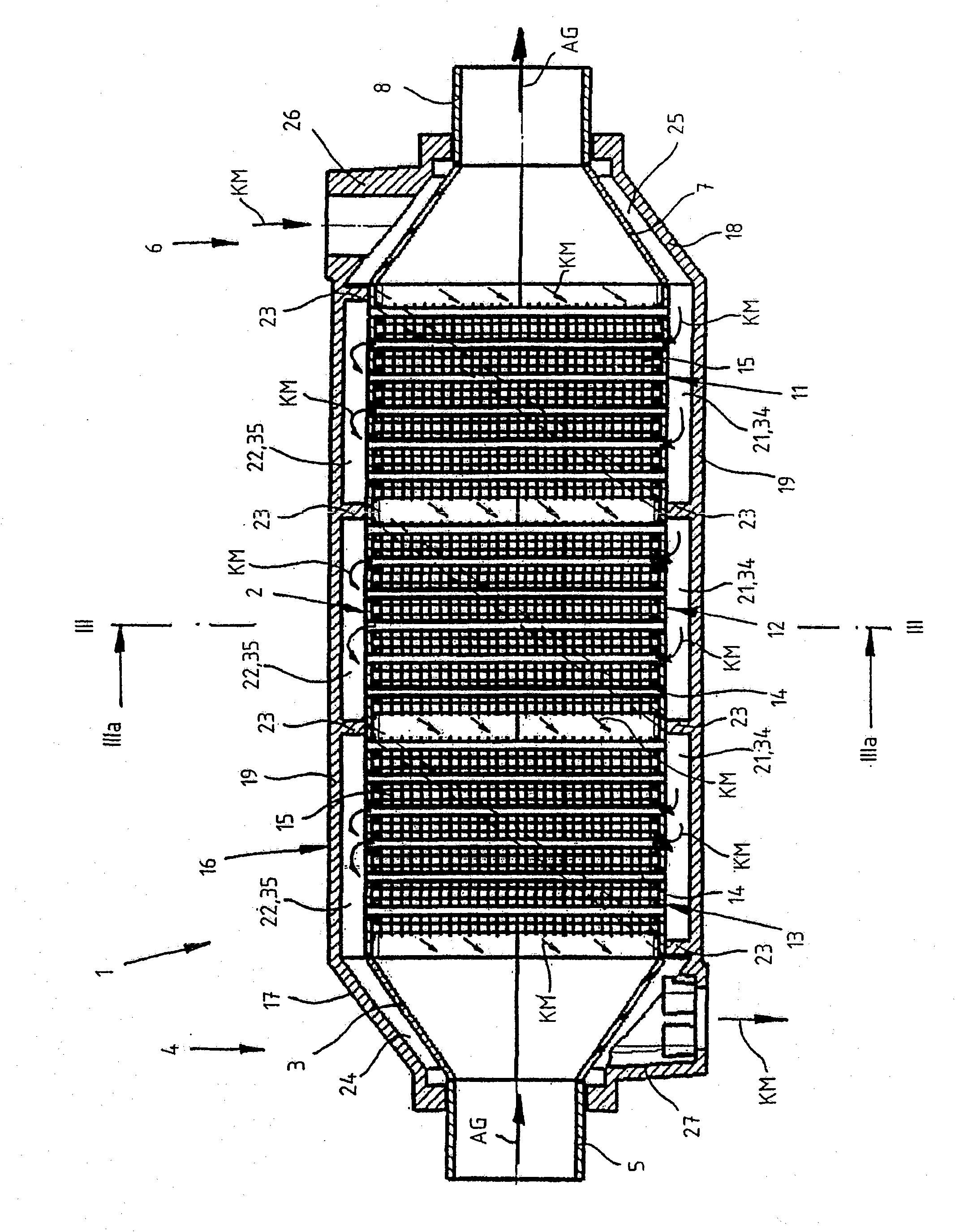

[0030] exist Figures 1 to 3 Indicated by 1 is an exhaust gas recirculation cooler for a large internal combustion engine not shown in detail, such as can be used, for example, on board a ship. In the exhaust gas recirculation cooler 1 , the hot exhaust gas AG leaving the internal combustion engine undergoes an indirect heat exchange with a coolant KM in the form of cooling water.

[0031] The exhaust gas recirculation cooler 1 has a heat exchange insert 2 that is rectangular in cross section and has a conical inlet region 3 for hot exhaust gas AG at one end 4 . The inflow region 3 is located downstream of the inflow connection 5 for the hot exhaust gas AG. At the other end 6 of the exhaust gas recooler 1 there is a conical outflow region 7 of the heat exchange insert 2 for the cooled exhaust gas AG. The outflow region 7 merges into a cylindrical outlet connection 8 for the cooled exhaust gas AG.

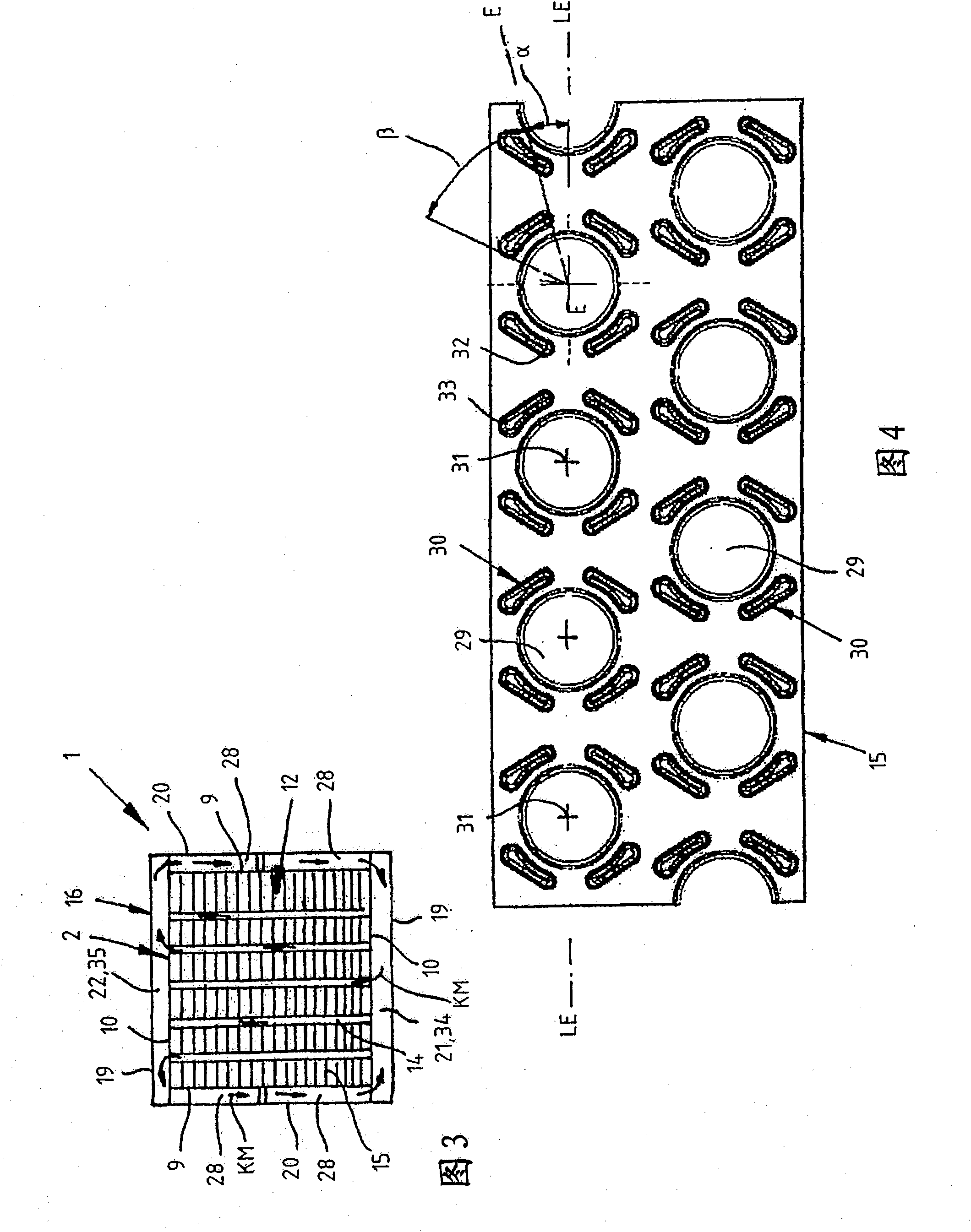

[0032]The heat exchange insert 2 has two closed side walls 9 facing each oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com