Retraction structure of safety syringe

A safety syringe and needle seat technology, applied in the field of retractable structures, can solve the problems of drug and blood contamination, deepening infectious diseases, stab wounds by medical staff and cleaning personnel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

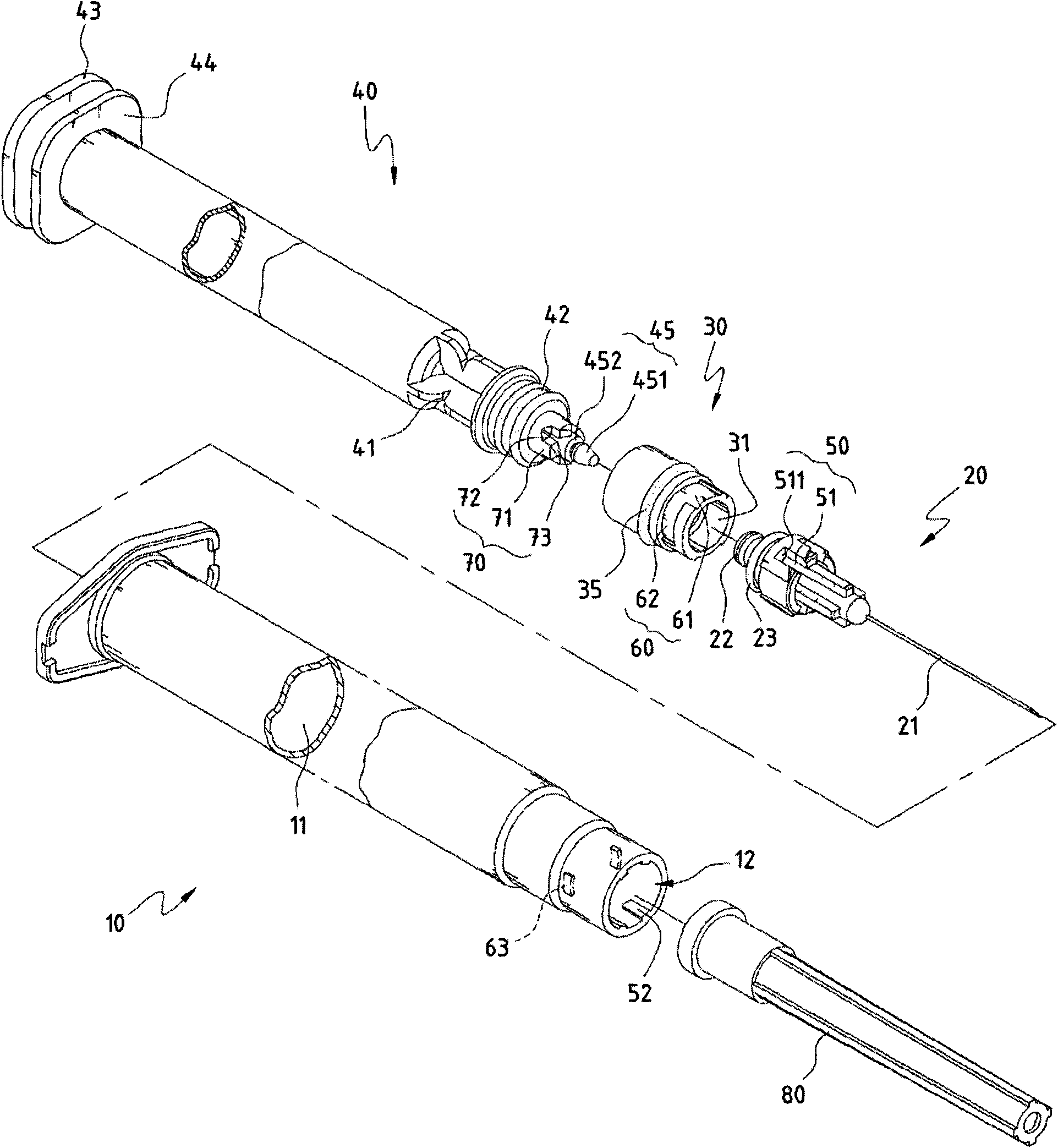

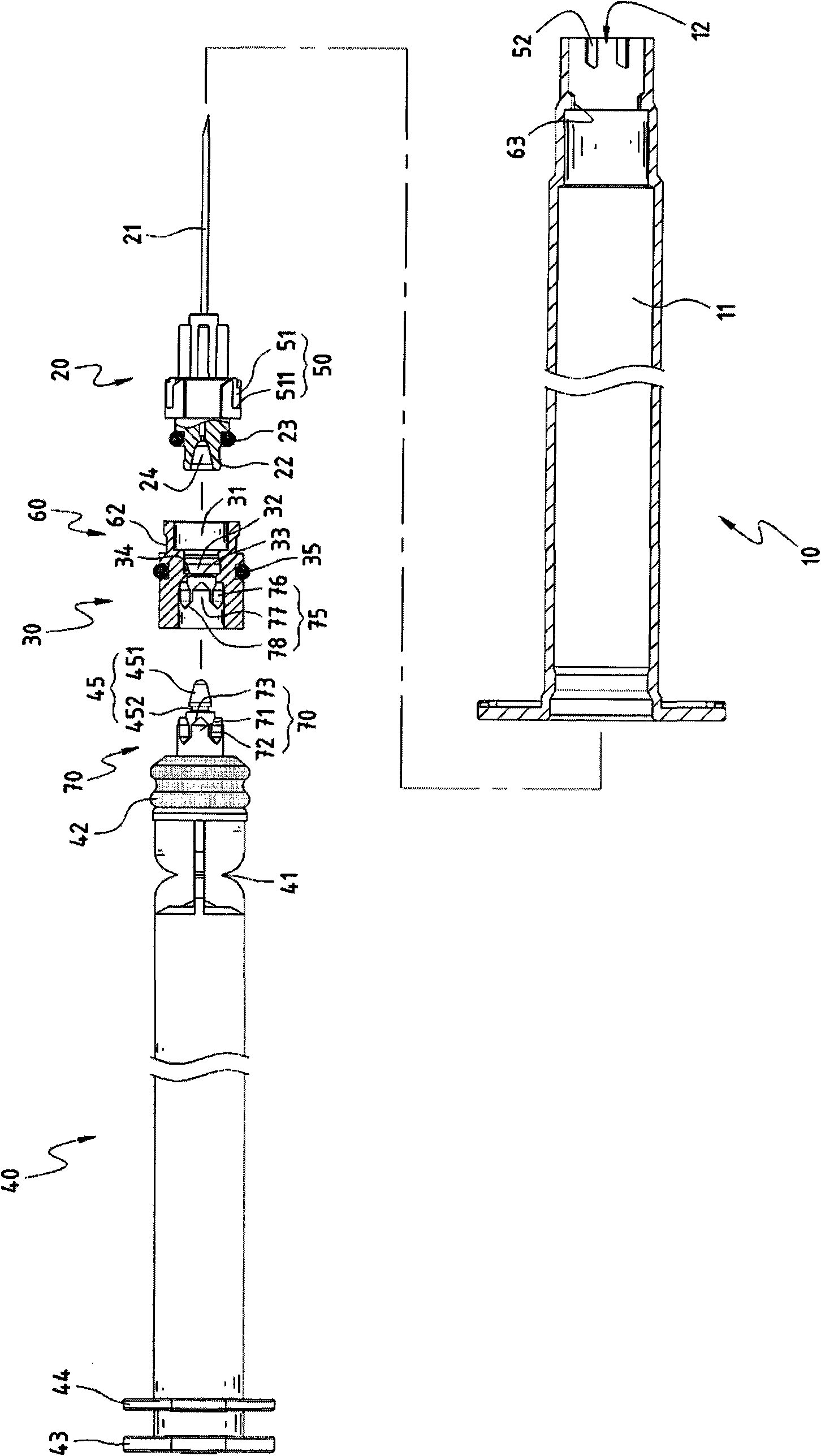

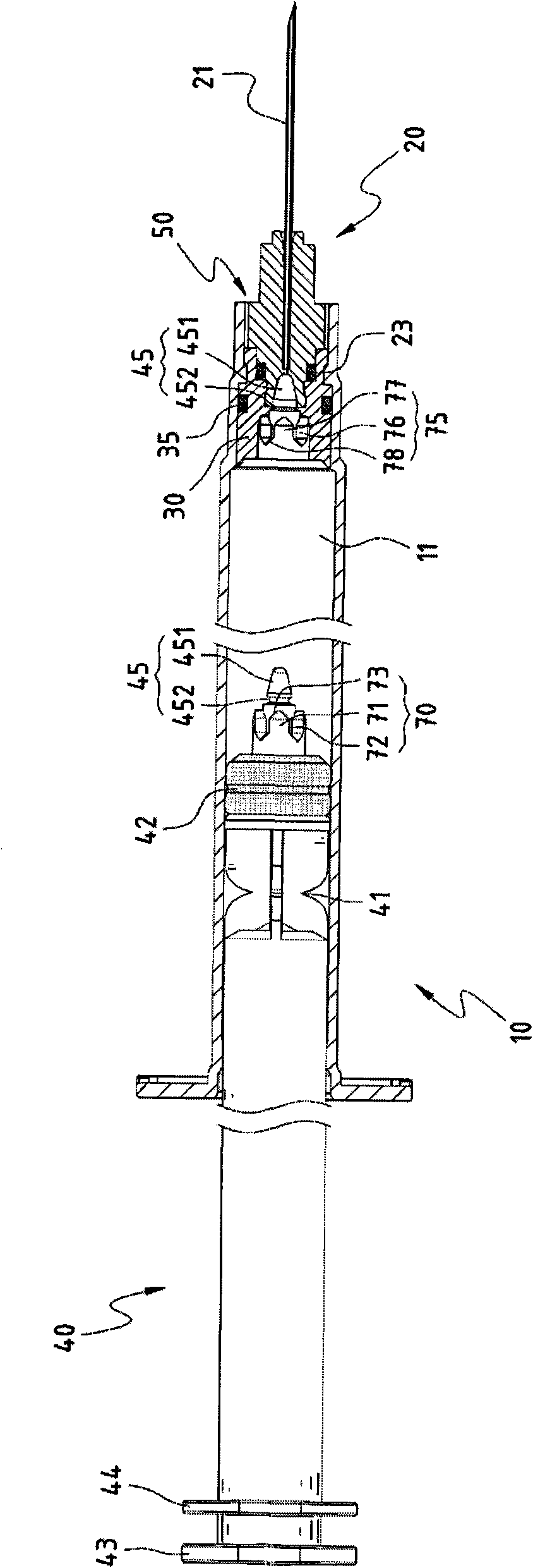

[0026] Now illustrate the present invention in conjunction with accompanying drawing and embodiment.

[0027] The main component symbols are explained as follows:

[0028] Cylinder body (10), chamber (11), open end (12), upper needle seat (20), injection needle (21), assembly end (22), O-ring (23), locking groove (24 ), the lower needle seat (30), the container (31), the connecting groove (32), the through hole (33, the retaining edge (34), the stop ring (35), the push rod (40), the break (41 ), rubber plug (42), adjusting end (43), extension piece (44), locking end (45), oblique cone edge (451), ring shoulder (452), limiting rotation unit (50), limiting rotation Seat (51), blocking surface (511), rotation limiting piece (52), L-shaped locking unit (60), opening part (61), limit part (62), guide block (63), rotating seat ( 70), rotary claw (71), card groove (72), guide inclined surface (73), rotary groove (75), rotary claw (76), card groove (77), guide inclined surface (78),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com