Acoustic barrel for aircraft engine nacelle including crack and delamination stoppers

A technology for engine compartments and aircrafts, applied in the field of inner sound boxes, which can solve the problems of lack of multi-segment sound boxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

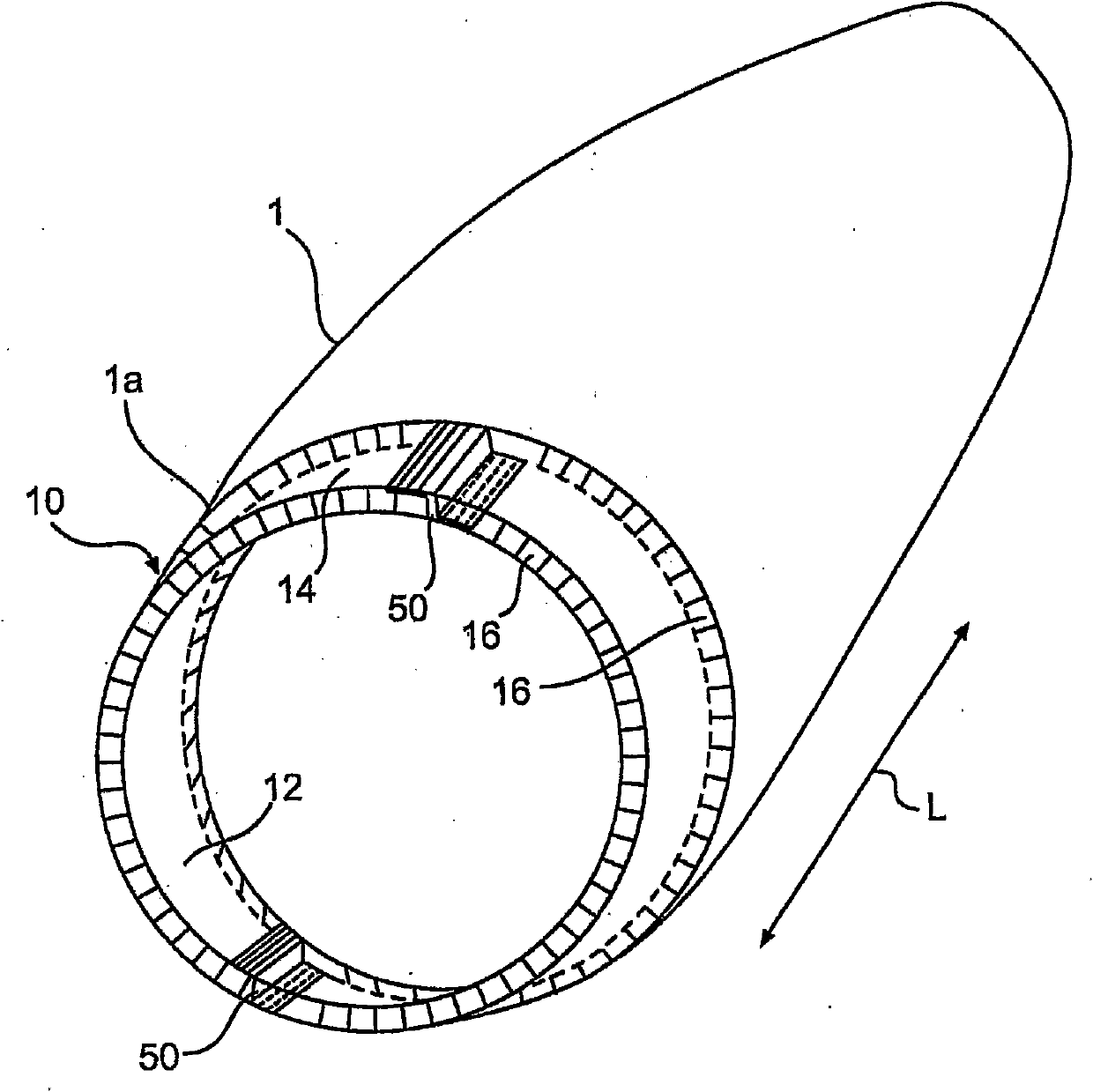

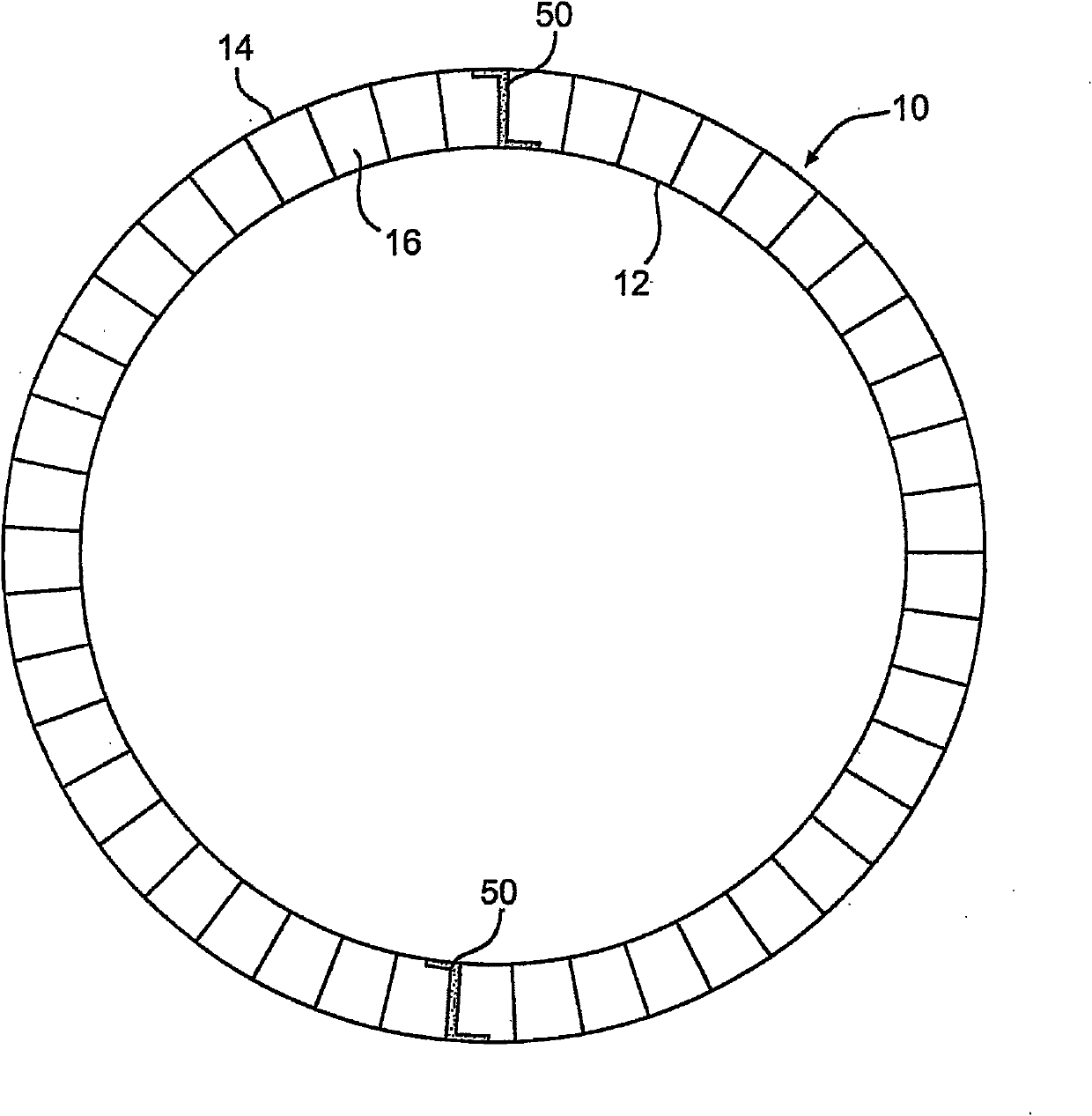

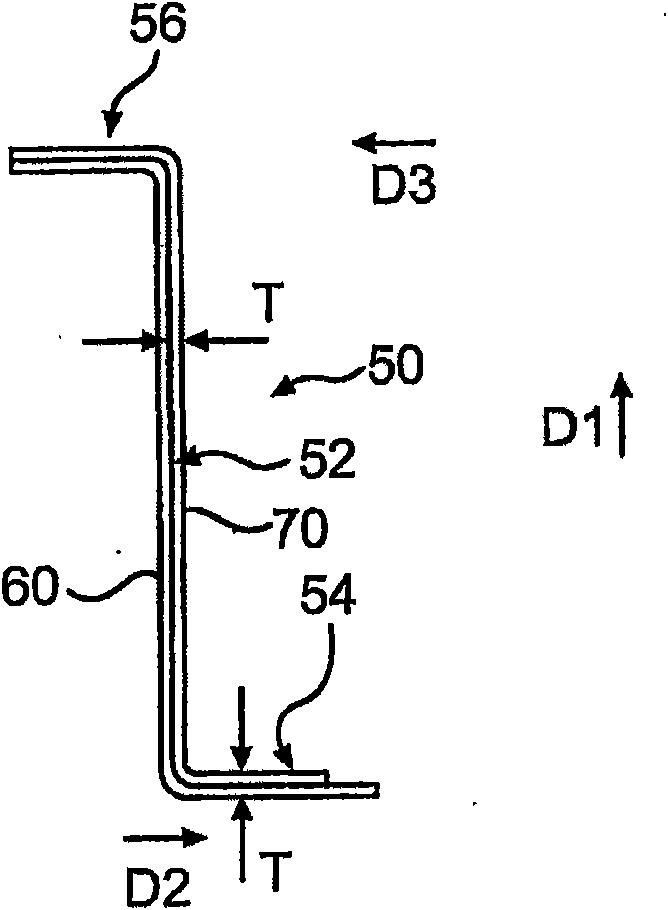

[0023] figure 1 There is shown an aircraft nacelle 1 comprising an inner acoustic box 10 at the inlet 1 a according to an embodiment of the invention. Such as figure 1 with 2 As shown, the casing 10 is a 360-degree single-piece annular structure. The receiver 10 includes an annular perforated inner panel or skin 12 , an imperforated outer panel or skin 14 radially spaced from the inner skin 12 , and an acoustic honeycomb core 16 disposed between the inner skin 12 and the outer skin 14 . The term "circular" includes along the length L of the nacelle 1 ( figure 1 ) diameter and shape configurations that vary in direction and are not intended to be limited to right cylinders. The inner skin 12, outer skin 14 and honeycomb core 16 may be of composite construction, such as graphite epoxy or the like. The inner skin 12 and outer skin 14 are bonded to the core 16 with an adhesive such as Henkel epoxy adhesive EA9258.1, or another adhesive material with comparable peel and shear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com