Method for producing a hydrocarbon cut with a high octane level and low sulphur content

A technology with high octane number and low sulfur content, which is applied in the fields of hydrocarbon oil treatment products, processing hydrocarbon oil, liquid carbon-containing fuel, etc., and can solve problems such as the decline of octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

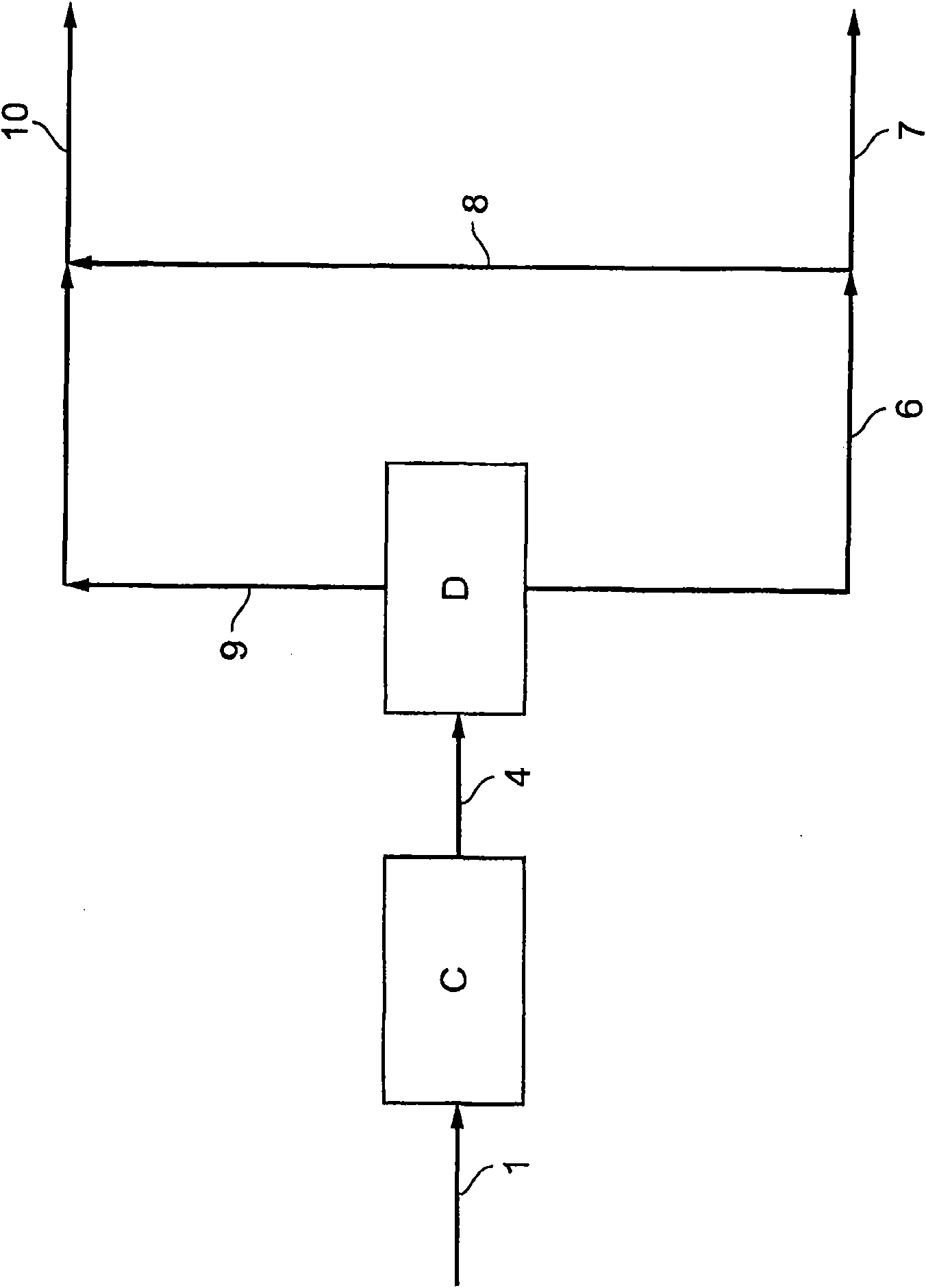

[0124] Example 1 ( figure 1 )

[0125] a) Obtain desulfurization catalytic cracking gasoline

[0126] The starting material is catalytically cracked gasoline to produce at least a similar high-quality gasoline and a raffinate that can be supplied to a steam-cracking unit.

[0127] FCC gasoline has the following characteristics:

[0128] ASTM D86 Distillation: Starting point: 35°C

[0129] End point: 220°C

[0130] Olefin content: 33.6% by weight

[0131] Aromatic compound content: 34.6% by weight

[0132] RON=93.00

[0133] Sulfur = 3,278ppm

[0134] The starting material (1) is selectively desulfurized on a Co / Mo catalyst (HR 806 type) under the following conditions: In the hydrodesulfurization unit (C), temperature: 260°C, P=2MPa, VVH=4h -1 , H 2 The / HC ratio was 200 l / l.

[0135] b) Extraction of desulfurized gasoline

[0136] The effluent obtained in the hydrodesulphurization step is sent via line (4) to unit (D) for the extraction of sulfolane ar...

Embodiment 2

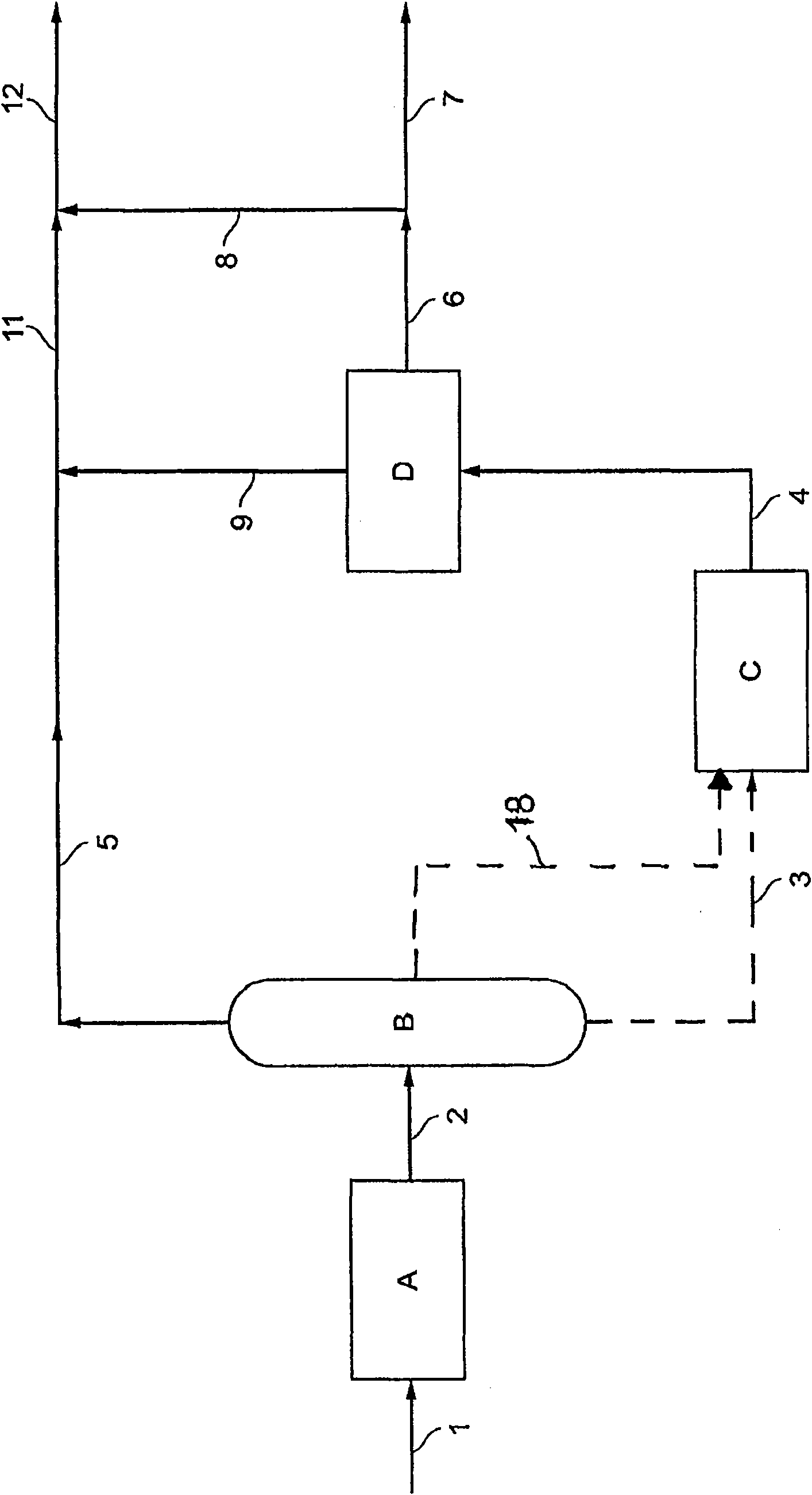

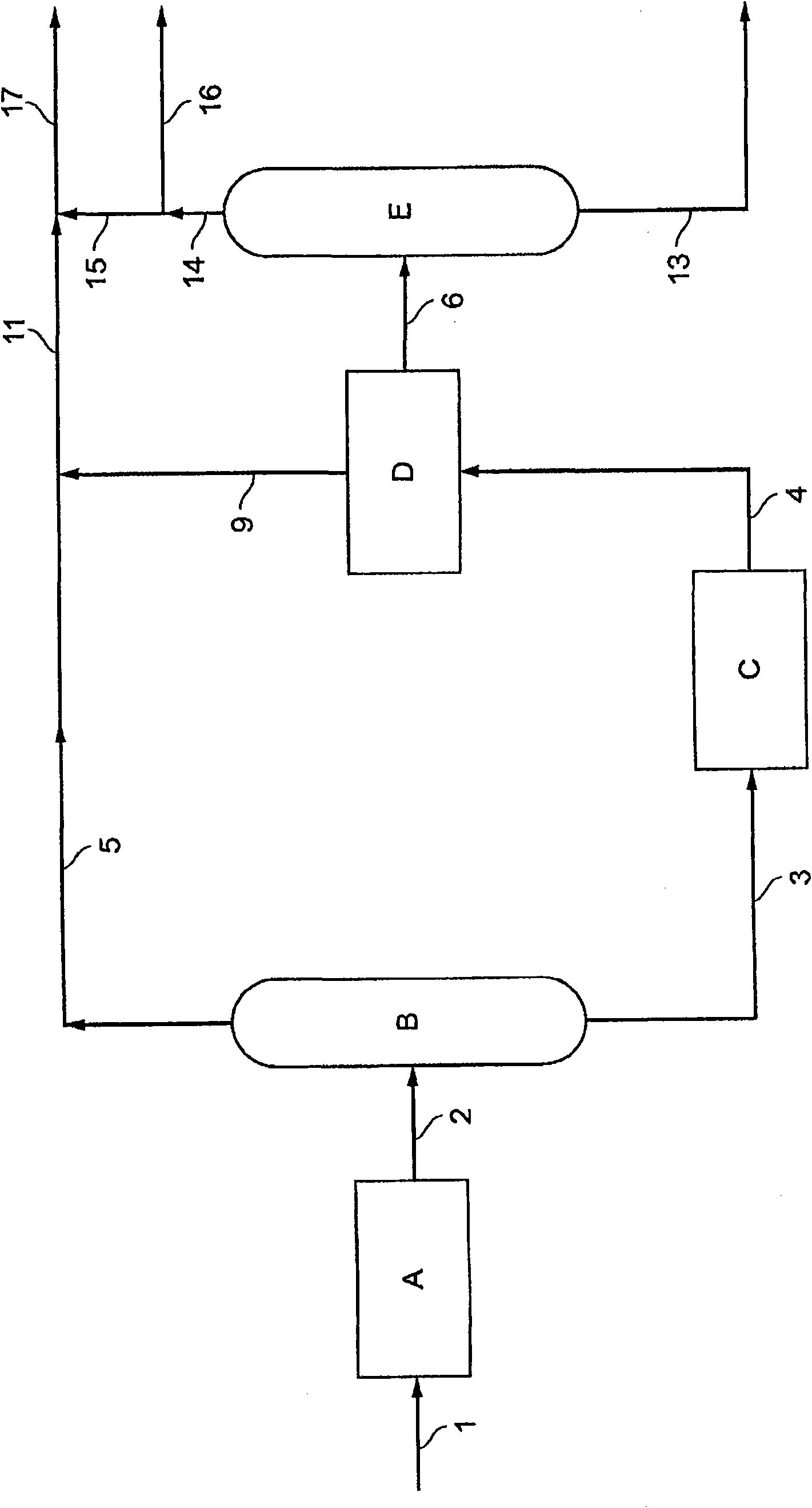

[0145] Example 2 ( figure 2 -selective mode)

[0146] a) Obtain a kind of desulfurization catalytic cracking gasoline

[0147] The starting material is catalytically cracked gasoline, from which it is necessary to recover the raffinate for sending to steam cracking while improving the quality of the gasoline produced.

[0148] FCC gasoline flowing through line (1) has the following properties:

[0149] ASTM D86 Distillation: Starting point: 35°C

[0150] End point: 140°C

[0151] Olefin content: 34.5% by weight

[0152] Aromatic compound content: 19.2% by weight

[0153] RON=91.40

[0154] Sulfur = 1,112ppm

[0155] It was processed over a Ni-Mo selective hydrogenation catalyst (HR845).

[0156] Gasoline is processed under the following conditions:

[0157] Temperature: 160℃; Pressure: 2MPa; VVH=4h -1 , H 2 The / HC ratio was 5 l / l.

[0158] The effluent flowing through line (2) is then subjected to fractional distillation in a column (step B).

[0159...

Embodiment 3

[0169] Embodiment 3 ( figure 2 -non-selective mode)

[0170] a) Obtain a kind of desulfurization catalytic cracking gasoline

[0171] The starting material is catalytically cracked gasoline, from which it is necessary to recover the raffinate for sending to steam cracking while improving the quality of the gasoline produced.

[0172] FCC gasoline flowing through line (1) has the following properties:

[0173] ASTMD86 Distillation: Starting point: 35°C

[0174] End point: 140°C

[0175] Olefin content: 34.5% by weight

[0176] Aromatic content: 19.2% by weight

[0177] RON=91.40

[0178] Sulfur = 1,112ppm

[0179] It was processed over a Ni-Mo selective hydrogenation catalyst (HR845).

[0180] Gasoline is processed under the following conditions:

[0181] Temperature: 160℃; Pressure: 2MPa; VVH=4h -1 , H 2 The / HC ratio was 5 l / l.

[0182] The effluent (2) is then fractionally distilled (unit B). At the top, the fraction with a final desulfurization AS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com