One-bath dyeing method of modified polyester/wool blended fabric

A dyeing method and technology of modified polyester, which is applied in the field of one-bath dyeing of modified polyester/wool blended fabric and one-bath dyeing of polyester/wool blended fabric. problem, to achieve the effect of reducing energy consumption, not easy to color difference, and high dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Modified polyester and wool in the same color but different shades

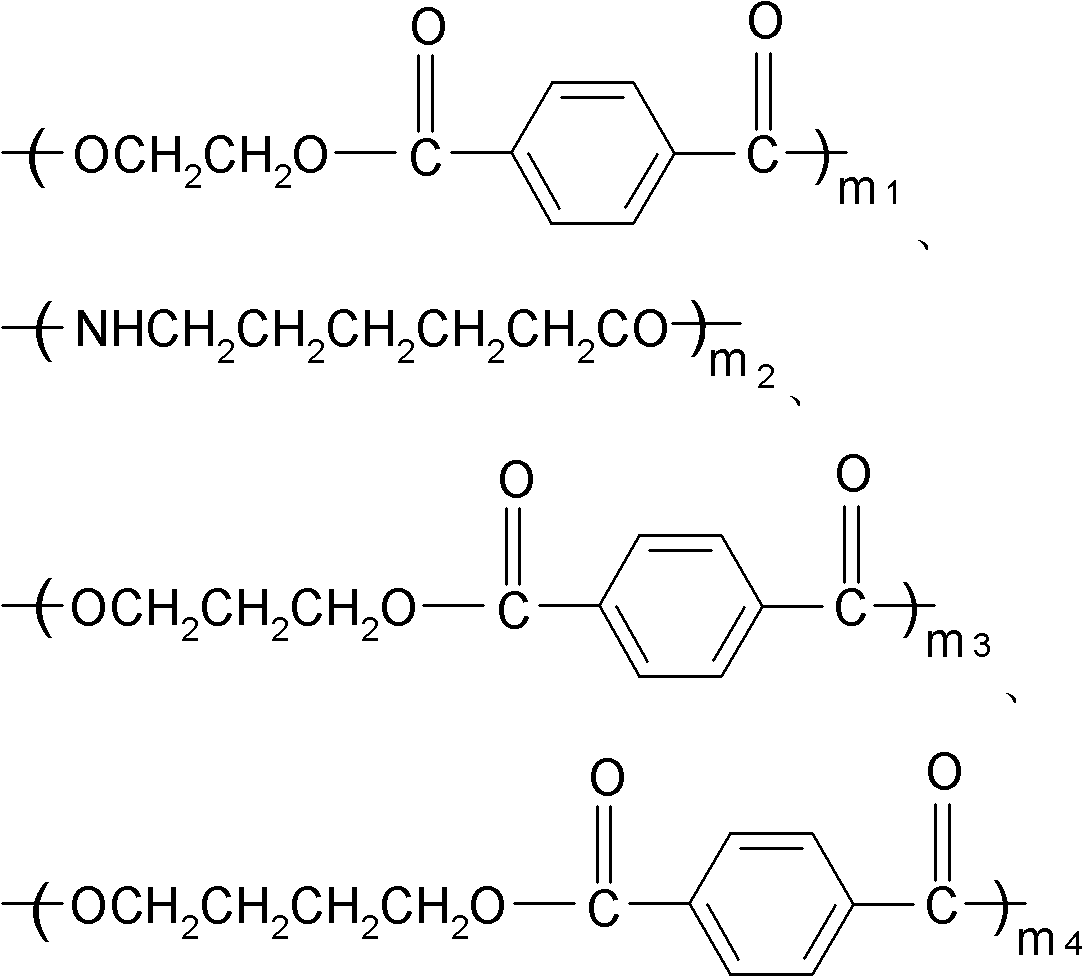

[0054] The structure of described modified polyester is:

[0055] where 101 2 <70.

[0056] The fabric is a modified polyester / wool 30 / 70 blended fabric with a fabric weight of 185g / m 2 , the dye formula is: Acid Black 10B 1.5% (o.w.f), Yuanming powder 10g / L, leveling agent TF-217A 1.5g / L, adjust the pH value of the dyeing solution to 4.5 with citric acid and sodium citrate, and fabrics at 25°C Dyeing, then the dyeing solution is heated up to 100°C at a speed of 3°C / min, kept for 60 minutes, cooled and drained, and then washed with water. The color fastness of the dyed product is tested, and the color fastness of the dyed product is tested. Dry and wet grinding The color fastness is grade 4.

Embodiment 2

[0058] Modified polyester and wool completely different colors

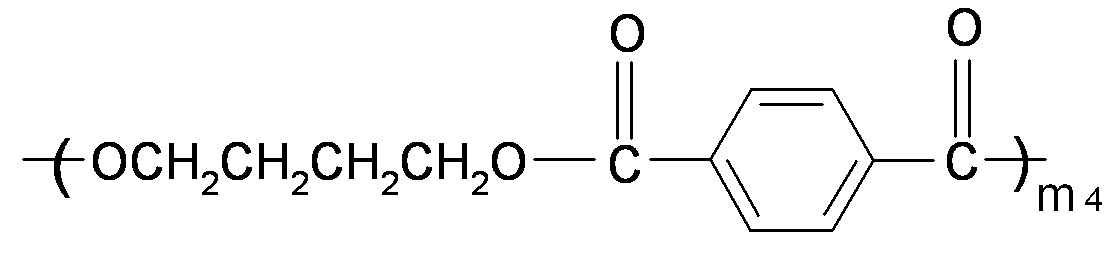

[0059] The structure of described modified polyester is:

[0060] where 101 2 3 <5.

[0061] The fabric is a modified polyester / wool 50 / 50 blended knitted fabric with a fabric weight of 210g / m 2 , the dye solution formula is: disperse red FB 0.5% (o.w.f), weak acid bright yellow 5G 1.2%, use glacial acetic acid and sodium acetate to adjust the pH value of the dye solution to 4~5, the fabric is dyed at 40 ° C, and then the dye solution is heated at 2 ° C Heat up to 100°C at a speed of 1 / min, keep warm for 45 minutes, cool down and drain, and then wash with water. The color fastness of the dyed product is tested. The color fastness to dry rubbing is grade 4-5, and the color fastness to wet rubbing is grade 4.

Embodiment 3

[0063] Modified polyester and wool are exactly the same color

[0064] The structure of described modified polyester is:

[0065] 101 2 <70.

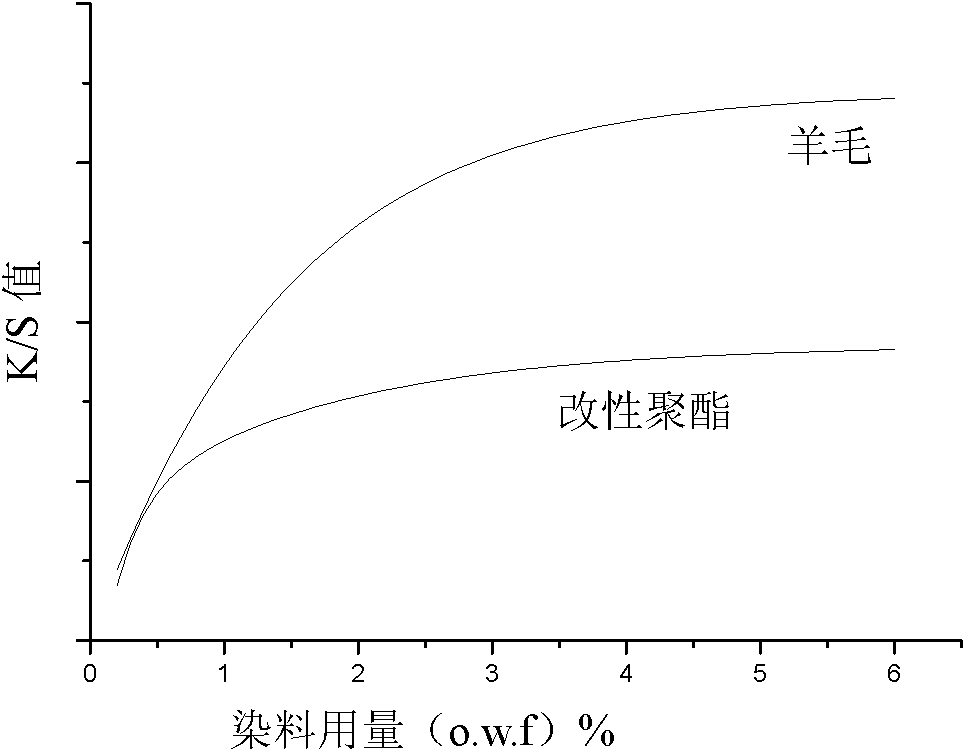

[0066] The fabric is a modified polyester / wool 40 / 60 blended knitted fabric with a fabric weight of 220g / m 2 , the color sample K / S value is 12.6, according to the computer color matching database, wool dyeing, only use weakly acidic black BR can meet the color sample color requirements, its consumption is 1.8%, according to the formula in the present invention to calculate the required amount of modified polyester Apparent depth value Δ(K / S) complemented by disperse dyes D is 5.76 (correction coefficient F is 1.2), and the calculated dye dosage in the final dye solution formula is: weak acid black BR 1.47%, disperse black 0.4%.

[0067] The formula of the dyeing solution is: Disperse Black 0.4% (o.w.f), Weak Acid Black BR 1.47%, Leveling Agent TF-217A 0.5~1.0g / L, Yuanmingfen 8g / L, adjust the dyeing solution with glacial acet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com