Method for operating otto-gas engine

An internal combustion engine, Otto technology, applied in the direction of internal combustion piston engine, combustion engine, mechanical equipment, etc., to achieve good efficiency and avoid knocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

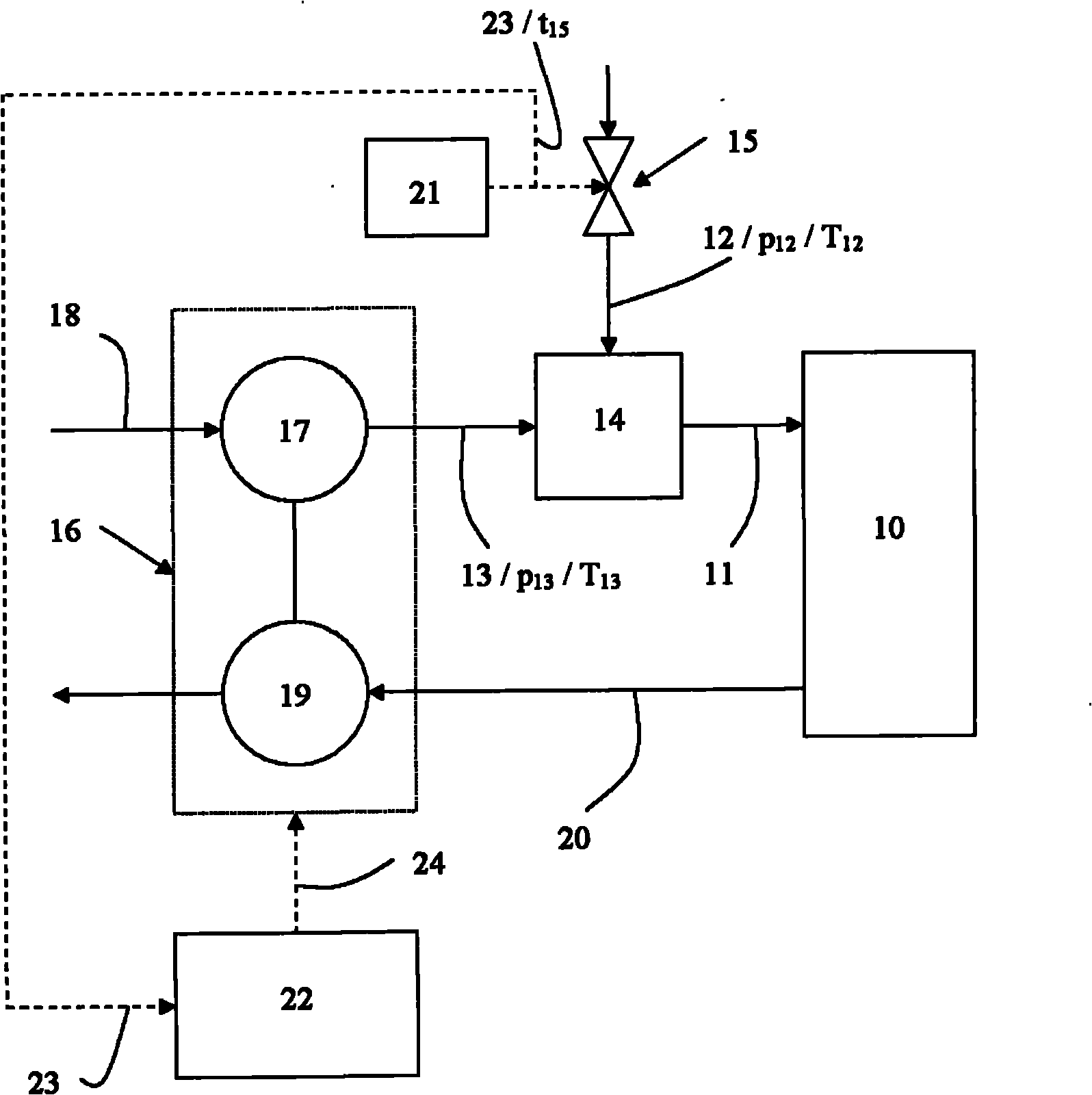

[0025] figure 1 A schematic block diagram of an Otto internal combustion engine, which is designed as a large gas engine and includes cylinders 10 , is shown. A mixture 11 of fuel 12 , ie gas, and combustion air 13 is supplied to the cylinder 10 for combustion of the mixture 11 , wherein the fuel 12 and the combustion air 13 are mixed in a mixer 14 .

[0026] Fuel 12 is mixed into combustion air 13 , which is compressed combustion air 13 compressed by means of an exhaust gas turbocharger 16 . The exhaust gas turbocharger 16 has a compressor 17 in which uncompressed combustion air 18 is compressed into compressed combustion air 13 , wherein the compressor of the exhaust gas turbocharger 16 17 is driven by a turbine 19 of the exhaust gas turbocharger in which exhaust gas 20 of the internal combustion engine is expanded.

[0027] As already mentioned, the fuel 12 is mixed into the compressed combustion air 13 , for which purpose at least one fuel control valve 15 is assigned to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com