Linear electrostatic sensor array method for measuring particle speed and device thereof

An electrostatic sensor and particle velocity technology, applied in measuring devices, fluid velocity measurement, velocity/acceleration/impact measurement, etc., can solve the problems of reducing the filter space selectivity, affecting the accuracy of velocity measurement, and the wave peak is not obvious, etc., to achieve The effect of convenient signal processing, simple structure and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

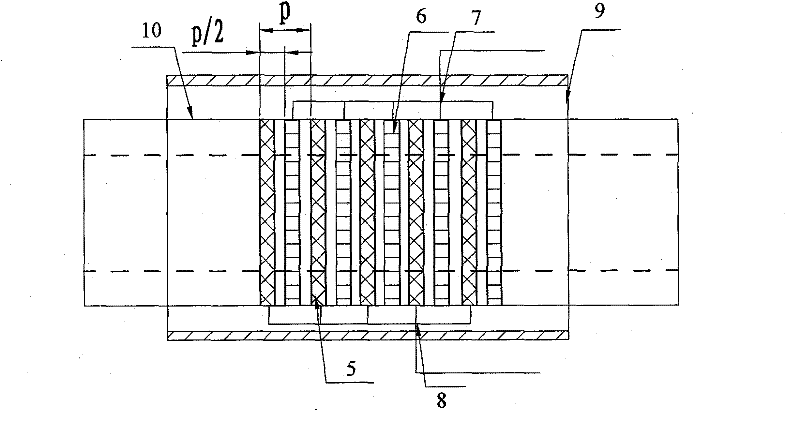

[0018]A linear electrostatic sensor array measurement method for particle velocity, taking two groups of first electrostatic sensor array 5 and second electrostatic sensor array 6 with the same structure and dimensions and insulating measurement pipeline 10, said first electrostatic sensor array 5 includes at least the first electrostatic sensor array 5 11 ring electrostatic sensors, the 12th ring electrostatic sensor, the 13th ring electrostatic sensor, the 14th ring electrostatic sensor, the 15th ring electrostatic sensor, the second electrostatic sensor array 6 includes at least the 21st ring electrostatic sensor, the 22nd ring electrostatic sensor , the 23rd annular electrostatic sensor, the 24th annular electrostatic sensor, the 25th annular electrostatic sensor, the 11th annular electrostatic sensor, the 12th annular electrostatic sensor, the 13th annular electrostatic sensor, the 14th annular electrostatic sensor, the 15th annular electrostatic sensor set Set in the insu...

Embodiment 2

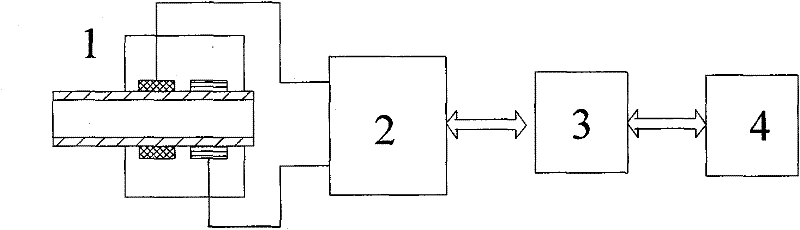

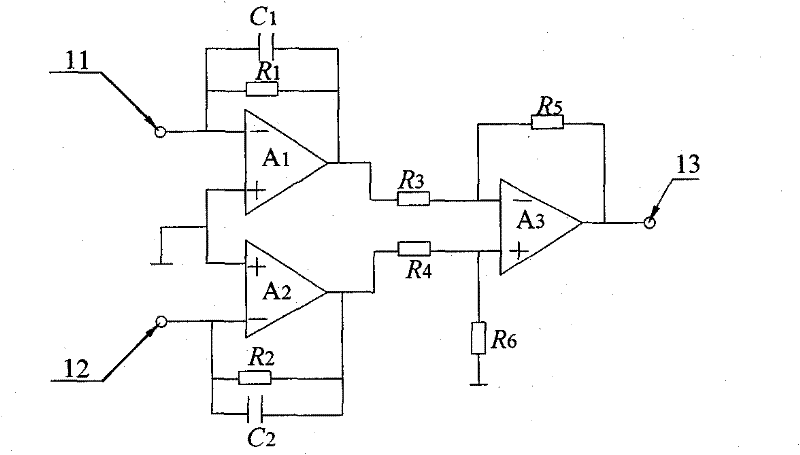

[0020] A device for implementing a linear electrostatic sensor array measurement method for particle velocity, comprising: a measuring probe 1, a pre-charge differential amplifier circuit 2, a data acquisition card 3 and a computer 4, the output terminal of the pre-charge differential amplifier circuit 2 and the The input end of the data acquisition card 3 is connected, the output end of the data acquisition card 3 is connected with the input end of the computer 4, and the computer 4 performs spectrum analysis on the output signal of the data acquisition card 3 and determines the peak frequency on the spectrum, and then calculates and obtains the gas-solid Two-phase flow particle average velocity, the measuring probe 1 includes: an insulating measuring pipeline 10, a first electrostatic sensor array 5 and a second electrostatic sensor array 6 provided on the insulating measuring pipeline 10, and an insulating measuring pipeline 10, the first A metal shield 9 is provided outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com